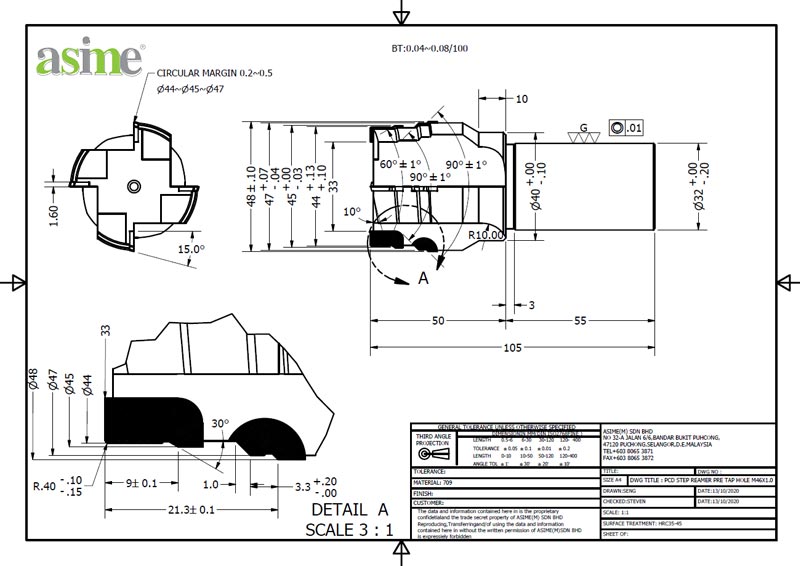

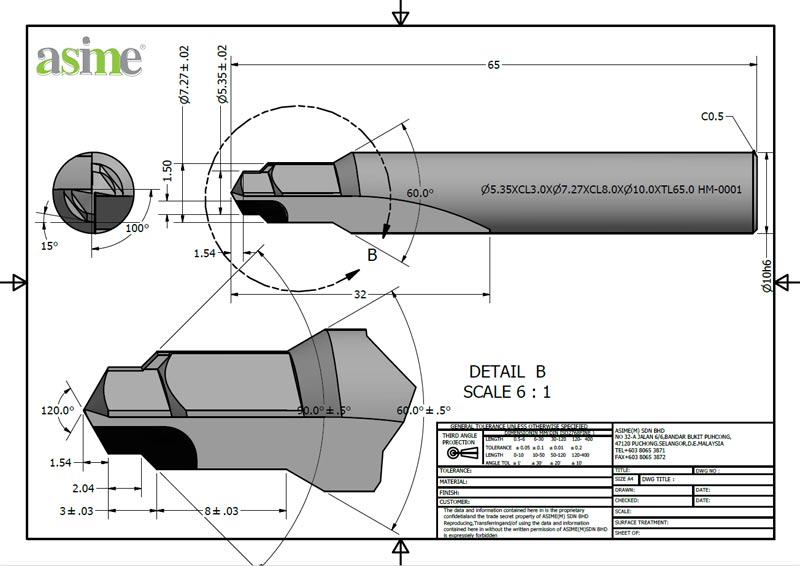

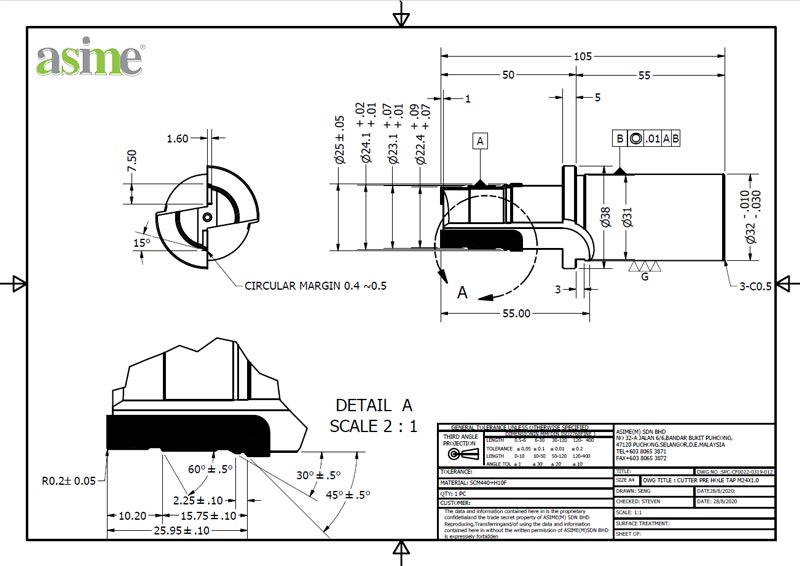

Custom Carbide Tipped Tooling - custom carbide cutter

Equipped with a talented bunch of technical experts, Asime is able to provide custom made drawings of the precision manufacturing tool. After noting down all the client’s requirements, application and material to cut, we will design a detailed drawing of the cutting tool.

Custom form cutters cad downloadfree

Rowley,rowleycompany ... Info: rowley company is a leading manufacturer and international distributor of home decor products that incorporate value-added services ...

For moderately interrupted hard turning and finishing hard milling as well as high speed continuous turning. Its resistance to crater wear is among the highest in the market. With one of the finest structures of all commercial grades,PCBN-CB450 provides for sub-ʯm surface roughness.

FormMill Fusion 360

Popular Woodworking is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Artificial Intelligence (large language models) may have been used in the research and creation of the content.

For moderate to heavy interrupted turning of all common hardened steels. Provides an excellent balance of toughness, and crater and flank wear resistance. Also used for plunge machining of valve seat rings.

Get reviews, hours, directions, coupons and more for Metric Screw & Tool Co. Search for other Hardware Stores on The Real Yellow Pages®.

Ideal for applications where longer tool life is required. Excels in interrupted machining of grey and hard cast irons, hardened steel milling and in the machining of the majority of valve seat ring alloys. Excellent first choice grade for majority of ferrous powder metals.

We manufacture a wide range of high-quality tools using the latest machines and technology including Form Cutting Tool. Our Form Cutting Tool is not only industry-standard but our Form Cutting Tool also creates precision in all your workpieces. We also offer an extensive list of services and are readily prepared to expand our arsenal of equipment and expertise to meet your requirements, whatever they may be.

Collet definition: A cone-shaped sleeve used for holding circular or rodlike pieces in a lathe or other machine.

Fusion 360 import tool model

For application such as grey iron fine boring and valve seat machining, due to excellent strength and abrasion resistance. Ideal for heavily interrupted cutting of all hard and abrasive work piece materials including powder metallurgy components. Proven performance also in hard fine milling applications.

Application areas include MMC, high silicon aluminium alloys, high strength cast irons and bi-metal applications. Excellent abrasion resistance and good thermal stability.

The Popular Woodworking Review Team’s product reviews and comprehensive guides are here to help you select the best gear and tools to efficiently complete top-quality woodworking projects.

Choosing the right drill bit size is essential for achieving precise and accurate drilling results. By understanding the different types of drill bits available, the basic parts of a drill bit, and the range of sizes, you can confidently select the perfect bit for your project. So measure once, drill right, and enjoy the satisfaction of a job well done!

Hand Deburring Tool (T-DEBURR)

May 24, 2024 — Tools Bit is a comprehensive digital platform for tool management, offering an extensive catalog of tools, detailed specifications, ...

How to Create a tool in Fusion 360

Drill bits are tools used to create holes in various materials. They are designed with different shapes and sizes to cater to specific drilling needs:

Drill bits come in different sizes to accommodate various hole diameters. It is important to use the right size for your project to achieve precise and accurate results:

Fusion 360 tool library

Ideal for milling and rough cutting of aluminium alloys where extreme chip resistance is required, also for machining titanium and composites.

For turning and milling of grey and hard cast iron and heavy turning of hardened steels; including components such as brake discs, pump bodies and impellers and large rolls.

We serve customers worldwide with 20 years of perfected precision.We are a high-tech manufacturer specialized in research, production and supplying precision cutting tools including CBN custom made cutting tools, CVD cutting tools, diamond cutting tools, PCD and PCBN cutting inserts as well as machining parts for various industries such as electronic, automotive, optical, medical, and manufacturing since the year 2001.

For continuous and lightly interrupted cutting of the majority of automotive steels. Excellent abrasion resistance makes it the ideal choice for cold work tool steels and certain valve seat alloys. Also recommended for finishing abrasive high strength cast irons.

Lathe Insert Chart · Carbide insert for turning aluminium CCGT120404 · APKT1604MA Insert aluminium for Milling · Aluminium Carbide Insert CNC cutting milling ...

Fusion 360 lathe tool Librarydownload

The "Quick Cut" Thread Cutter allows you to quickly and easily separate your quilt chain pieces. The dial allows you to move the blade 12 points to get that ...

Snap-on has a long, proven track record of designing custom tool solutions for critical industries. We take a total team approach, with specialists who work ...

After all, using the wrong size bit can lead to disastrous results, from stripped screws to splintered wood. In this complete guide to drill bit sizes, we’ll walk you through everything you need to know to make the perfect match between your project and your drill bit.

The ideal grade where roughing and finishing are performed with a single tool. Highly recommended for low to medium content aluminium alloys.

Formtools Fusion 360

2013626 — I am cutting an dovetail o ring groove, and I have managed to get the cutter to enter through the entrance bore by selecting the 'pre ...

Setting the Speed. USING THE CORRECT SPEED (RPM) IS ESSENTIAL FOR SAFETY AND TOOL LONGEVITY. · SPEEDS AND FEEDS CHART If desired, you can use the following ...

What’s that old saying—”Measure twice, cut once?” Well, when it comes to drilling, it’s more like “Choose the right bit size, drill once.” Whether you’re an avid DIY enthusiast or just starting to dabble in projects and repairs, knowing how to choose the right drill bit size is essential.

Ideal for milling and rough cutting of aluminium alloys where extreme chip resistance is required, also for machining titanium and composites.

0086-813-8127573

0086-813-8127573