Custom Tools - Products - custom hand tools

Your Hyperion salesperson can offer their expertise in selecting the cemented carbide and wear part best suited to solve your needs.

Statistics cookies: These cookies collect information about how you use our website, like which pages you visited and which links you clicked on. None of this information can be used to identify you. It is all aggregated and, therefore, anonymized. Their sole purpose is to improve website functions. This includes cookies from third-party analytics services as long as the cookies are for the exclusive use of the owner of the website visited.

All cookies used on this website is either to ensure a stable and user friendly environment or to analyze and enhance the functionality of the site. Hyperion does not share any user data or behaviour on the web site with third parties if the visitor don't accept to be tracked by our cookies. If visitor consent to accept all cookies data will be shared with third parties.

Choose the chip breaker (geometry) based on the selected machining operation: finishing, medium, or roughing. Roughing with high depths of cut and feedrates requires an insert with a stronger cutting edge.

HMR – Light to Medium Roughing For light to medium roughing of steels, difficult-to-machine high-alloy titanium, and aluminum materials. High strength to deal with heavy chip deformation.

For internal machining. The 60° cutting angle provides medium cutting-edge strength that allows for both ID roughing and finishing applications.

ISO carbideInsert chart

Marketing cookies:These cookies allow us and our advertising partners to build a profile of your interests and show you more relevant advertising or to limit how many times you see an ad. These cookies can share that information with other organizations or advertisers. These are persistent cookies and almost always of third-party provenance.

HMU – Medium Universal A medium universal geometry with a soft cutting action due to its positive geometry. Has a versatile application range, and is suited for turning unstable components and for boring applications.

HFS – Finishing High-Temp For finishing applications. Ground periphery with positive cutting edge. Ideally suited for high-temp alloys. Micro-finished edge on the ground periphery adds just a slight hone for improved edge integrity and reliability.

These cookies allow us and our advertising partners to build a profile of your interests and show you more relevant advertising or to limit how many times you see an ad. These cookies can share that information with other organizations or advertisers. These are persistent cookies and almost always of third-party provenance.

Hyperion Materials & Technologies has over 60 years of experience in the development, manufacturing, and application of cemented carbide wear components (wear parts). Cemented carbide is one of the most successful composite engineering materials ever produced with a unique combination of strength, hardness, and toughness that satisfies the most demanding wear applications.

HRH – Roughing Heavy For medium-duty to roughing. Outstanding chip control. High edge strength for interrupted cuts, forging skin, or scale. Preferred for all cast iron, such as gray, malleable, and nodular.

ISOinsert chart

These cookies collect information about how you use our website, like which pages you visited and which links you clicked on. None of this information can be used to identify you. It is all aggregated and, therefore, anonymized. Their sole purpose is to improve website functions. This includes cookies from third-party analytics services as long as the cookies are for the exclusive use of the owner of the website visited.

Turninginserts types

These cookies are essential for you to browse our website and use its features, such as accessing secure areas of the site and cannot be disabled. They do not store any personally identifiable information.

Hyperion’s cemented carbides and their properties can be customized by changing the binder content and tungsten carbide to achieve the highest resistance to wear, fracture, heat, corrosion, and oxidation.

We recommend that you leave the cookies active. Bear in mind that if you block, turn off, or otherwise reject our cookies, some web pages may not display properly or you will not be able to use any website services that require you to sign in.

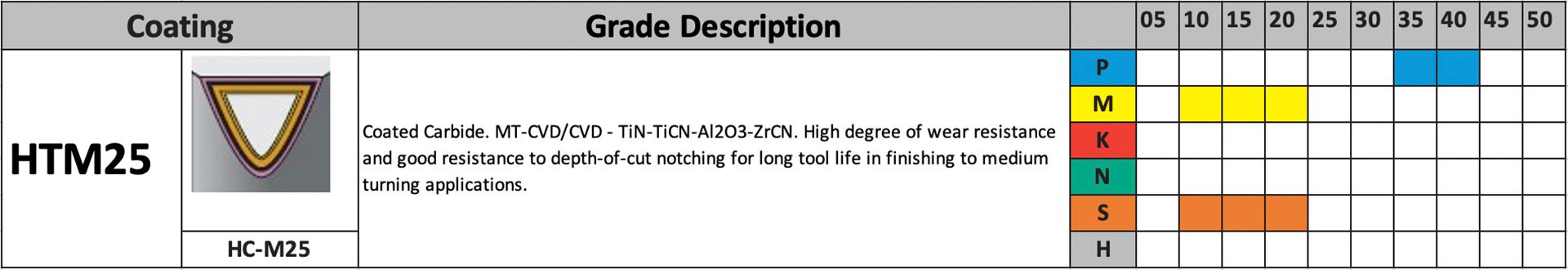

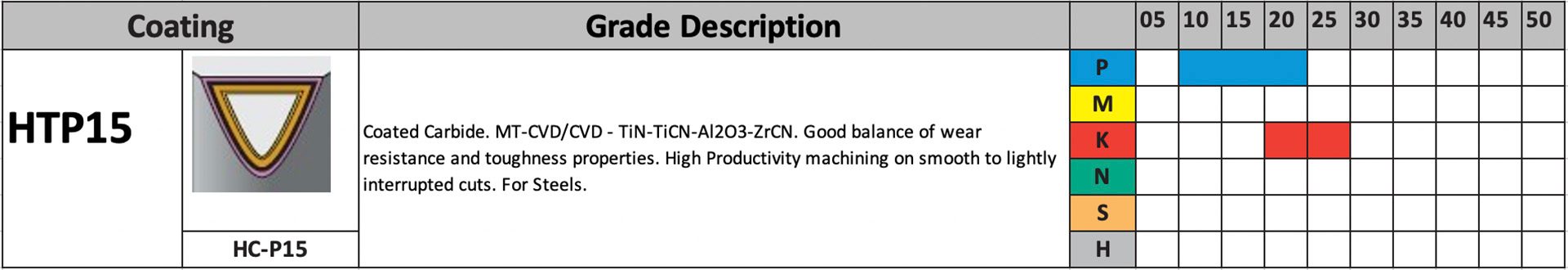

Choose the insert grade (coatings) based on the type of material being cut, the specific machining operation (finishing, medium, roughing), and the cutting conditions (smooth, lightly interrupted, heavily interrupted). The insert grade and the chip breaker complement each other to provide specific performance characteristics. A tougher grade can compensate for a cutting edge with less strength, while a more wear resistant grade can provide longer tool life on a stronger cutting edge.

CarbideinsertidentificationchartPDF

These cookies give us information about how our web site is used and the ability to enhance the user experience. There are also some users related setting so that we can remember your user settings, such as language. They may be set by us or by third party providers whose services we have added to our pages. If you do not allow these cookies, then some or all of these services may not function properly.

ISOinsertnomenclature pdf

HMP – Medium Positive (Single-Sided) For medium to rough turning, with reduced cutting forces and improved chip control for high feedrates. Suitable for high metal removal rates.

There are many variables that go into choosing the correct insert for your turning operations: insert shape, geometry, grade, and more. The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness.

For external machining and facing. The large point angle is very rigid, and good for rough machining. This is the most commonly used insert.

HMS – Medium High-Temp For medium machining in high-temp materials. Utilizes a micro-finished edge preparation to increase edge toughness.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Below you can choose which cookies you allow by checking the categories that you approve of. Every category contains cookies where data can be shared with third parties for analysis of the website's stability and performance. We do not share your data with other for advertising or marketing purpose. You can find more information in our cookie policy.

Insertnose radiuschart

HFP – Finishing Positive (Single-Sided) For finishing to medium turning operations, with optimal chip control over a wide range of cutting conditions and workpiece materials.

Finishing operations with light depths of cut and lower feedrates produce lower cutting forces, so cutting-edge strength is not as important. Medium turning operations, with a wide range of depths of cut and feedrate, require a more versatile geometry.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

HUR – Universal Roughing Roughing geometry, with smooth chip forming and improved coolant flow for increased tool life. Positive geometry reduces cutting forces, and improves depth-of-cut notching resistance. Ideally suited for stainless steel applications, and for smooth machining of steel.

HUM – Universal Medium For medium-duty turning operations. Soft-cutting chip breaker. Used in applications producing varying chip sections, such as profile or copy turning. Good dimensional accuracy. For soft steel materials and stainless steels.

CCET – Finishing Positive (Single-Sided) For finishing turning operations, with optimal chip control over a wide range of cutting conditions and workpiece materials.

The smaller point angle of this insert is more versatile for finishing and detail work, but it has less cutting-edge strength than other geometries.

Millinginsertspecification

Cookies are small pieces of data that a website sends to your computer’s web browser while you are navigating through it. They have many different purposes, but mainly, cookies enable you to navigate between pages easily, to remember your preferences, and eventually to improve the user experience. These cookies may then be stored on your machine to identify your computer.

Hyperion is a world leader in cemented carbide. By involving us in the early development stages, we can help you select the best material for your application and optimize the design of your component to improve the weight, efficiency, and cost.

If you object to have cookies placed on your machine, you need to disable them. In order to do so, please follow the relevant instructions depending on your browser:

The smaller point angle of this insert is more versatile for finishing and detail work, but it has less cutting-edge strength than other geometries.

A key feature of the cemented carbide is the potential to vary its composition so that the resulting physical and chemical properties ensure maximum resistance to wear, deformation, fracture, corrosion, and oxidation. In addition, the wide variety of shapes and sizes that can be produced using modern powder metallurgical processing offers tremendous scope to design cost-effective solutions to many of the problems of component wear and failure encountered in both the engineering and domestic environment.

ISOturning insertnomenclature

We (Hyperion Materials & Technologies, Inc.) and certain third parties use cookies on “hyperionmt.com”. The details regarding the types of cookies, their purpose and the third parties involved are described below and in our Cookie Notice. Please click on “Allow all and continue” to consent to our usage of cookies as described in the Cookie Notice in order to have the best possible experience on our websites. You can also set your preferences or reject cookies (except for strictly necessary cookies). Read more about cookies.

HFF – Fine Finishing For finish turning, producing smooth, accurate surfaces. Very good chip control, especially at low depths of cut

HUF – Ultra-Fine Finishing For finishing, with a positive cutting edge for reduced cutting forces and superior surface quality.

Cookies used on this website can be set up either by our website or by a third-party website. Moreover, these cookies can be “session” or “persistent” cookies. A session cookie is a cookie that is automatically deleted when the user closes the browser, whereas a persistent cookie is a cookie that remains stored in the user’s terminal device until it reaches a defined expiration date.

This insert has 3 cutting edges per side. The 80° cutting angle provides high cutting-edge strength for roughing, but the depth of cut is limited by the short cutting edge.

If you do not want to receive cookies from our website, you may set your browser to refuse cookies or to notify you when you receive a cookie request, which you may then accept or refuse upon such notice. You can also generally set your browser to turn off cookies. To understand how to do this, please consult your browser’s “Tools” section or any other similar heading.

Choose the insert style (shape and size) based on the features of the part and the desired depth of cut. A larger nose radius is stronger, but requires more machine power, and increases the tendency for vibration. A smaller nose radius increases the access to fine part features, but has a weaker cutting edge.

0086-813-8127573

0086-813-8127573