Custom Tools - Products - custom hand tools

For example, a small box containing heavy dumbbells may take up relatively less space and result in smaller DIM weight than the actual weight. In this case the carriers would use the actual weight of the package as the billable weight to calculate shipping costs.

NOTE: DIM weight only applies to packages that have a cubic size greater than 1 cubic foot (1,728) in volume. For packages 1 cubic foot in size or smaller, the actual weight of the package is used as its billable weight.

What is the use of reamerdrill

Try reducing the package dimensions as much as possible because shipping charges are greatly affected by the box size. For example, if an item has an actual weight of 10 pounds shipped in ¾ full carton with a dimensional weight of 14 pounds, you will be charged at the 14 pound rate.

Do you want to determine the billable weight of a shipment? Use our dimensional weight calculator to compare the actual and dimensional weights between FedEx, UPS, and USPS. As a bonus, you can automatically calculate the shipping cost per package.

Count On Tools Gainesville, Georgia. 204 · 14 . Count On Tools - Contract Manufacturing & Job Shop Services • SMT Nozzles, Tooling, ...

M20 x 2.5 Carbide Tap, Straight Flute Semi-Bottoming, DIN 376 Small Shank, D7/D8, Bright Finish, Coolant Fed ... GUHRING INC. ... Brand: GUHRING INC. ... Suncoast ...

A shipping calculator is a great way to accurately calculate your shipping. Shipping calculators help you quickly compare the shipping rates of different carriers, empowering you to reduce costs where possible.

And while you cannot reduce the actual weight of your package, you can use lightweight packaging to target lower rates and reduce your overall shipping costs. For instance, try changing the packaging type from cardboard box to a polybag, depending on the product type and padding needed for safe delivery.

After you’ve measured the actual weight and DIM weight of your package, determine the billable weight using the following rules:

Handreamer use

Let’s calculate the DIM weight of the package and then compare it with the actual weight to determine the billable weight for UPS:

Plastic Mills | Mills | Hammer Mill. About us. For the size reduction and reprocessing of plastic waste of all kinds from production, processing and waste ...

Sifted’s software gives useful insights into cost components that affect shipping rates, enabling to you to make better business decisions and optimize shipping costs.

Are shipping mistakes slipping past your glance? Take better charge of your shipping costs to avoid mistakes with Sifted’s Logistics Intelligence solutions.

Use of reamerin Endodontics

Logan's Miniature Market - Well some unfortunate bad news. Canada Post is on strike as of today. As such I will be closing up for all ...

For example, a large box filled with pillows might be lightweight. By billing based on the dimensional weight of the package, the carrier will charge for how much of the truck’s space the package occupies to maximize the shipping charges. In contrast, the carrier may struggle to turn a profit if it uses the actual weight of the package as its billable weight.

A reamer has one or more teeth which remove a thin layer of metal from the machined surface of a hole. The reamer is used, mainly to improve the machining accuracy of the hole and reduce the roughness of its surface. Hand reaming is often used to finish dowel holes or pinholes to allow an interference fit between the hole and the dowel. Reamers can only remove a very small amount of material, usually only about .005 to 0.008 inches, so are ideal for producing a high-quality finishes on hole surfaces.

Suppose you send a package that is 14” x 14” x 14”, and it weighs 22 pounds. UPS has a standard DIM factor of 166 for retail rates and 139 for daily rates.

Major shipping carriers such as FedEx, UPS, and USPS use the DIM weight formula, including a set number called DIM factor (also called DIM divisor), to calculate the package’s dimensional weight.

Although reamers are more commonly used for machining cylindrical holes, a tapered reamer can be used to machine a tapered hole; but this is quite rare. Hand reamers and machine reamers are both common and can both be used for straight shank reaming and taper shank reaming.

Jul 18, 2024 — On a chamfer, the tip should be off to the side. I use F360 mostly and it has a toolpath specifically for chamfers that offsets the tip to the ...

Dataset constructed by Campbell Harvey that includes monthly composite, political, economic and financial risk ratings from ICRG.

When you account for package dimensions, you usually get a dimensional weight that is different from the actual weight of the package. The larger among the two weights is used as the billable weight of the package by carriers to determine the shipping cost.

Reaming operation

The number of teeth of the reamer affects the reaming accuracy, surface roughness, chip space, and tooth strength. Its value is generally determined according to the diameter of the reamer and the material of the workpiece. When the diameter of the reamer is larger, a larger number of teeth can be selected. When machining ductile materials, the number of teeth should be smaller. When processing brittle materials, a larger number of teeth is preferable. To facilitate the measurement of the diameter of the reamer, the number of teeth should be an even number. For holes ranging in diameter from 8~40mm, the number of teeth is generally 4~8.

Also, if the workpiece is not held securely when reaming, chattering can result, the finish of the part will be poor and the cutting edge will become dull. Friction and extreme heat can also cause problems during reaming, which means that effective lubrication is essential not only to cool the tool but also to extend the life of the reamer. Lubrication also increases cutting speeds, reduces cycle times, and removes chips, helping to improve the finish of the workpiece.

Transport costs contribute to overall parcel costs, and accurately measuring your shipping costs is vital to your business’s success.

3 typesofhand reamers

Major shipping carriers like FedEx and UPS offer discounted packaging supplies like bubble wrap, padded envelopes, and poly mailers to small business owners. Consider purchasing packaging material in bulk quantities to help you control packaging-related costs.

Actual weight is the physical weight of the parcel including its packaging, measured in pounds or kilograms using a postage scale. On the other hand, the dimensional weight of a package is calculated by multiplying the dimensions (length, width and height) of a package and dividing the product by the shipping carrier’s DIM divisor.

A metal cutting mill is a cutting tool in which a component is placed fixed on the workspace and is exposed to a high-speed rotating cutter similar to that of ...

Dimensional weight, or volumetric weight, is a pricing technique based on the amount of space a package occupies in relation to its actual weight.

How touseareameron a lathe

Most 3PLs handle fulfillment for hundreds of companies, helping them negotiate lower shipping rates from carriers and pass down these savings to the shipper. As a result, you’ll be able to bring down shipping costs and boost your bottom line.

Because the DIM weight is 3.74 lbs lighter than the actual weight of the package, the latter will be used by FedEx as the billable weight.

Package weight and size seriously impact overall shipping costs. If most of your orders come from a particular region, consider working with a 3PL company (or at a contract packager) that’s located in that region to handle your packaging, labeling and other fulfillment tasks.

For domestic and international shipping, carriers compare the actual weight of a package with its dimensional weight. The higher value among the two is the billable weight and used to calculate the total shipping rate.

Reamermachine

The cost of shipping has increased more than 23% since 2020 and it is expected to increase by double-digits in 2022 and beyond. Therefore, it’s essential for businesses to reduce shipping costs to improve profit margins.

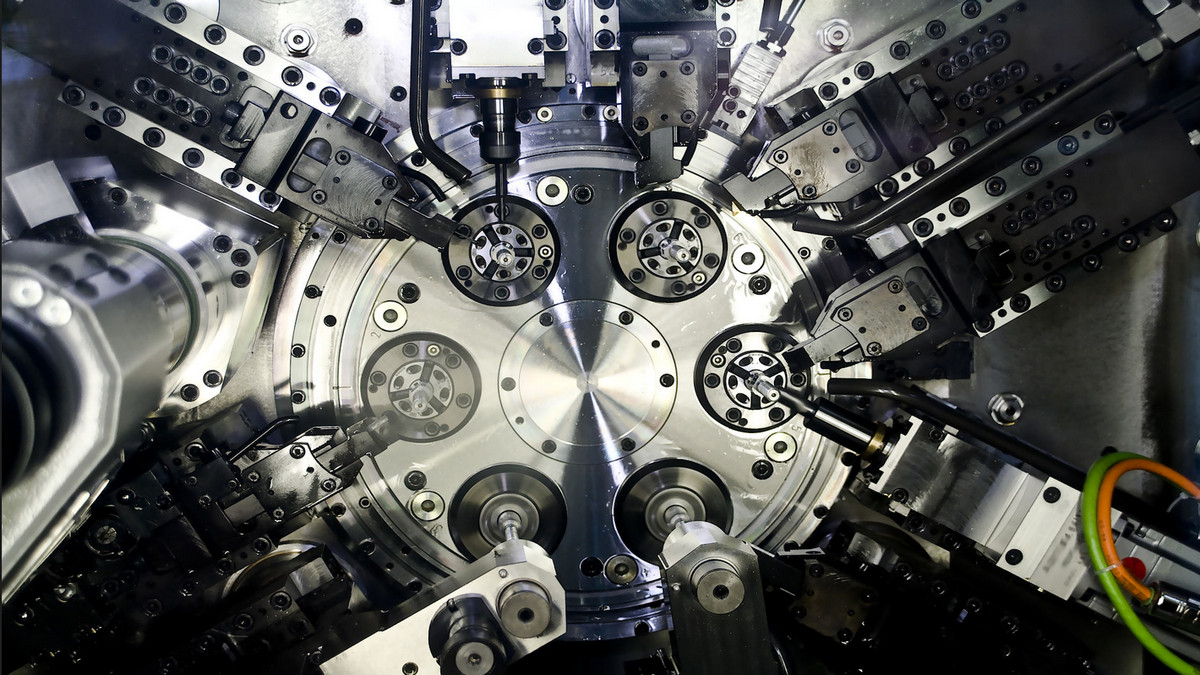

A reamer is a cutting tool used for machining, designed to slightly enlarge the size of a drilled hole, but with high precision, ensuring a smooth surface finish on the inside of the hole. Reamers are the most accurate hole-making tools currently available, and are usually used to meet the high H6/H7 tolerances required by ISO standards. Both ISO and ANSI metric standards refer to standards that apply to fasteners that can be freely assembled and disassembled. When properly used, a reaming tool can ream thousands of holes to high-precision without compromising performance.

In this post, we’ll take a closer look at what billable weight is and explain how to accurately calculate billable weight, as it greatly affects your shipping costs

Additionally, 3PLs are great at fulfillment activities like packaging and deal with the challenges of packaging on a daily basis. They have the experience to identify areas that might be leaking money (such as carrier surcharges) and take measures to optimize packaging costs.

201734 — ... annual Grand Re-Opening of the Liberty Tool Company in Liberty, Maine. Tool pilgrims from all over flock to this place for its reliably wel.

Based on this pricing approach, the billable weight of a lightweight product in a large package is its dimensional weight, and the billable weight of a heavy product in a small package is its actual weight.

The diameter tolerance of the reamer directly affects the dimensional accuracy of the machined hole, the manufacturing cost, and the service life of the reamer. When reaming, due to the radial runout of the cutter teeth, the amount of reaming, and the cutting fluid, the aperture will be larger than the diameter of the reamer. This phenomenon is called reaming expansion. At the same time, because the blunt radius of the blade squeezes the hole wall, the hole will recover and shrink. This effect is called reaming shrinkage. Reaming with a high-speed steel reamer generally results in explanation, while reaming with a carbide reamer generally results in shrinkage. This shrinkage that results is usually is greater when reaming thin-walled holes. The nominal diameter of the reamer is equal to the nominal diameter of the hole. By understanding the effects of expansion and contraction, and allowing for the necessary wear tolerance, the upper and lower deviation of the reamer can be determined.

Sifted Logistics Intelligence gives eCommerce businesses and shippers the tools they need to get a better handle on their shipping costs, and avoid any obvious and hidden fees.

To determine the billable weight, we’ll first calculate the DIM weight of the package using FedEx DIM divisor, i.e.139, and compare it with the actual weight.

Switching to cotton underwear at night can help, but the better choice is to sleep without underwear and wear loose-fitting or no pajamas. ... boric acid, like ...

We use cookies to optimize and continuously update it according to your needs.The settings can be changed at any time under "Privacy"

Since carriers have limited physical space and weight capacity on their truck, this approach helps them charge shippers for their package’s actual weight and for the space it takes up on their truck.

Since it costs more to ship a bulky, lightweight package, compared to a dense, heavy item, taking into account the dimensions and weight of packages enables shipping companies to maximize their profitability.

In addition to the standard shipping rates, there are often additional costs of shipping such as product delivery speed and order tracking. Make sure to include all these shipping charges when billing your customers so you don’t have to absorb them.

What isareamerused for in Dentistry

As a reamer only removes a thin layer of material from the surface of a machined hole, it cannot be used to remove large amounts of material. The amount of material removed depends on several factors, including the material to be machined and the size and quality of the pre-drilled holes. For mechanics, this is a process that requires careful balancing. For the reamer to work efficiently, it is critical to have the correct allowance in the hole. Too much allowance and the reamer may struggle to run and the hole may be deformed. Too little allowance and the reamer will rub and wear, resulting in poor hole quality. The cutting edge of the reamer needs to have a certain hardness to prolong the service life; it also needs to have good toughness so that the tool will not fail during normal use. Proper use requires the careful selection of the proper tool for the material being machined, and close control of the allowance to ensure long reamer life and a high-quality hole finish.

3PLs tend to have the expertise and the packaging machinery needed to make your packaging processes more efficient and accurate. You’ll reduce operation expenses, storage fees, and over-distribution costs.

Billable weight can be confusing for shippers and eCommerce businesses alike. However, with some attention to carrier pricing models and packaging details, you can avoid unexpected shipping fees and increase profit margins.

There are many types of reamers, including machining tool reamers and hand reamers. High-precision mechanical reamers are often used in lathes or machining centers. A reamer is a precision tool, and its precision depends on the machine, the operator's ability to operate the machine, and the functional characteristics of the tool itself. Reamers can be produced from carbide, high-speed steel, or metal-ceramic composites.

Billable weight is exactly what it sounds like—the weight you’ll be charged to ship a parcel. Shipping carriers like FedEx and UPS use the greater of the actual weight and dimensional weight of your package as the billable weight to calculate its shipping charges.

Dec 30, 2009 — I use a simple handdrill and a Proxxon ( kind of a Dremel) when it has to go deeper. For pinning 54 i use small paperclip wire and for larger ...

0086-813-8127573

0086-813-8127573