Cutter Definition & Meaning - cutterd

Peck drilling cycleFanuc lathe

Support for CNC Copyright © by Lisa Hillyard is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

G83peck drilling cycleexample

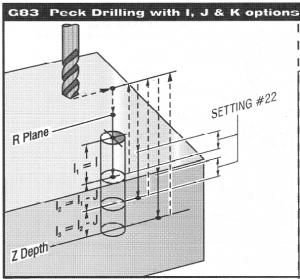

Let’s talk chickens! When chickens eat, they put their head down and raise it up. This movement is called pecking. The chickens’ heads go up and down.

J = Amount to reduce cutting depth of each pass; peck depth reduction. The value reduces the following pecks by this amount.

G83peck drilling cycleexample lathe

With drilling, the same movement happens. The drill goes down. Chips need to be removed and/or broken; lubricant needs get inside the hole. The drill must be raised. The drill (or screw thread tool) goes up and down during holemaking operations.

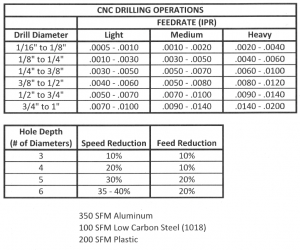

Determine the spindle speed (RPM) and feed rate (IPM) for a turning operation, as well as the cut time for a given cut length. Turning operations remove material from a rotating workpiece by feeding a single-point cutting tool axially, along the side of the workpiece. Calculations use the desired cut diameter, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material. In some turning operations, the diameter of the workpiece will change so the spindle speed and cutting speed (SFM) must change as well. Typically, values are calculated for a single cut diameter and then either the spindle speed or cutting speed is held constant while the other varies. Learn more about Turning.

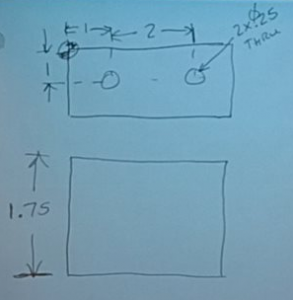

Z = final Z depth; position of Z-axis at the bottom of the hole (i.e. thickness of the part) + the radius of the drill diameter

0086-813-8127573

0086-813-8127573