cutters must template — Blog & Press - cutters must

Fusion 360woodworking plugin

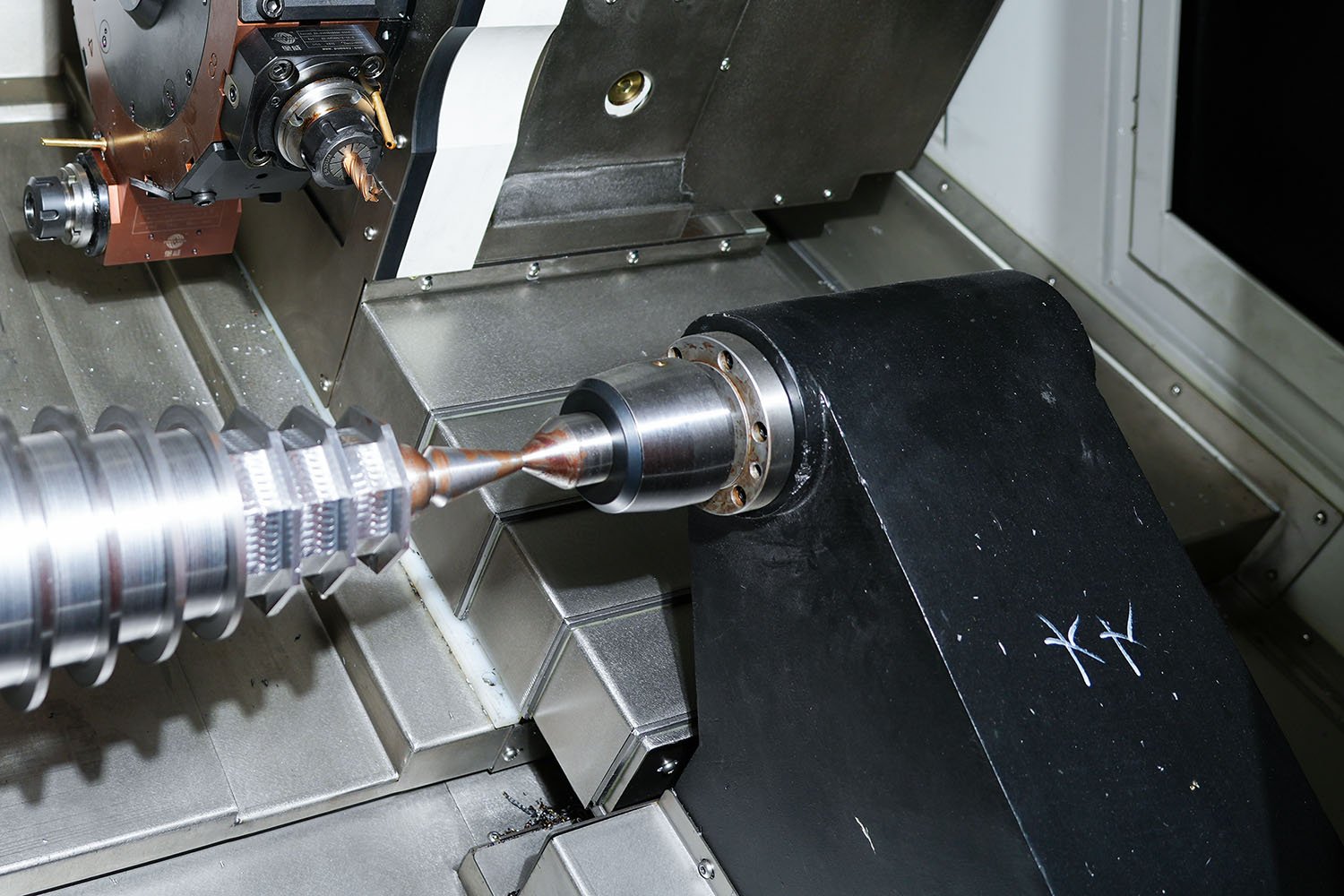

The length to diameter ratio of the workpiece determines whether to engage a tailstock. Therefore, take the holding length into account while determining the length to diameter ratio (length of the job held by the chuck).

Fusion 360plugin development

When using CNC lathes, when precise and accurate parts are crucial, the programmable tailstock is typically employed. Based on whether the components are long/slender or heavy, this type aids in determining the appropriate amount of holding pressure.

In conclusion, a tailstock is a machinist's best friend since it offers stability to prevent or reduce the bending and vibrations that occur while a workpiece is machined. Axles for cars are one example of a long part that needs precise machining.

BestFusion 360plugins

Address: BUILDING 2, SHUNMAO HARDWARE BUSINESS PARK, NO.7 RONGGUANG ROAD, RONGLI COMMUNITY, RONGGUI, SHUNDE, FOSHAN CITY, GUANGDONG PROVINCE, 528306, CHINA

When working with lengthy workpieces that are prone to bending under their own weight during machining, the tailstock's primary purpose is to offer support.

Smartlathe is one of the leading manufacturers of CNC machine tools in China. We are dedicated to simplifying the transition from manual to CNC control. Smartlathe pride ourselves in helping you with turning solutions of 3-Axis horizontal CNC Lathe, CNC Turning Machine, and CNC Turning-Milling Center & Vertical Machining Centers.

fusion 360add-ins install

The most widely used tailstock is a manual body with retractable barrel, while a manual body with programmable barrel tailstock helps hold long and slender parts.

Fusion 360modules

Fusion 360scripts

In wood lathes, the tailstock is crucial in supplying counterforce when holding the workpiece with a spindle spur. It is generally recommended to run the lathe at a safe pace and to always engage the tailstock to achieve a tight clamp.

In addition, when conducting machining operations on the cross-sectional face of the workpiece, the tailstock is used to hold lathe cutting tools such drill bits, reamers, threading tools, etc. These tools are placed by clamping them in the barrel of the tailstock, and the feed for the machining operations is provided by the handwheel. To supply powerful cutting force without any deflection when using the tailstock as a tool holder, it must be assured that the tailstock is fixed in position.

On a CNC machine lathe, the tailstock is used to hold and support the free end of a workpiece while it is being machined. It is situated opposite the headstock. The longitudinal rotating axis of the work piece is retained steady and set precisely parallel to the lathe bed thanks to a tailstock.

On a lathe, machining activities entail rapidly rotating long, slender workpieces.By turning the tailstock of the lathe, you can prevent the workpiece from vibrating and bending unintentionally as a result of this.But what precisely is a tailstock and how does it benefit the lathe's machining?This paper provides a detailed guide to the tailstock of a lathe by discussing the components, functions and types of tailstock.

fusion 360add-ins missing

In addition, this article discusses practical aspects of everyday machining, such as methods of aligning the tailstock to achieve high quality output.

For the manufacturer, the misalignment brought on by an uneven circumference or an undesirable taper might be very expensive. Such a product will also harm other components that are in contact with it. To ensure high-quality outputs, it is crucial to comprehend the tailstock alignment procedure.

If the workpiece has a length to diameter ratio less than 3:1, engaging the tailstock is not necessary. However, it is advised when the ratio is more than 3:1. In extreme situations where the ratio is larger than 10:1, a steady rest and a tailstock are strongly advised. The term "steady rest" refers to a holding mechanism that supports the workpiece circumferentially. It is positioned on the lathe bed similarly to a tailstock to offer workpiece rotation that is smooth and eccentric-free. Additionally, the tailstock offers solid support to heavier components that bend or distort during milling. Generally speaking, when the holding length (length inside a headstock chuck) is short, using the tailstock is also recommended.

0086-813-8127573

0086-813-8127573