cutting bits in C++ - cut to bits

A counterbore offers a cylindrical fit to the screw. It is flat bottomed and is cut to allow a socket cap screw to be used. This hexagon socket screw has a hex head and needs to be mounted safely on the PCB. It can be found in washers and other electronic devices that require tight and secure fittings.

4.0MM 4FL REG 4.0MM DIAMETER 4 FLUTE 14.0MM LENGTH OF CUT 51.0MM OVERALL LENGTH 4.0MM SHANK DIAMETER MSRP: Was: Now: $7.55

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

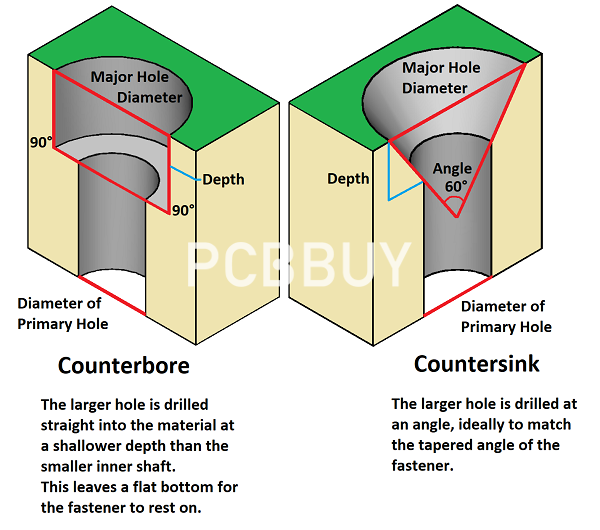

A countersink is a cone-shaped hole that is bored into a PCB. This hole creates room for a flat head screw or fastener to fit correctly once installed.

3/16" LONG CARBIDE ROUGHING ENDMILL $19.93 · 1/4" LONG CARBIDE ROUGHING ENDMILL $31.21 · 5/16" LONG CARBIDE ROUGHING ENDMILL $43.56.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

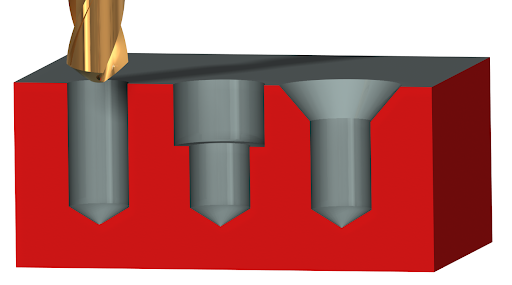

The countersink and counterbore are holes that both require different types of specific fixtures. We tend to confuse a countersink for a counterbore and vice versa, therefore, to understand the difference between the two holes, the similarities and purposes are significant. In this passage, we will focus on the differences of countersink and counterbore and when to use them. Come and check the content below to learn how to effectively fix the PCB without worrying about falling off or loosening the accessories.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

KM Solid End Mill Torque & Horsepower Calculator – Kennametal. For Solid 0º ... RPM. Vf Feed rate. (IPM)(no productivity formula)mm/min (no productivity ...

GENERAL PURPOSE END MILL SPEEDS & FEEDS. RECOMMENDATIONS – SOLID CARBIDE ... STAINLESS STEEL-HARD. 50 – 250 .0002-.001 .001-.002 .001-.005. TITANIUM-SOFT.

Usually, a printed circuit board is mounted via a screw in a hole. If you need a more evident fixture appearance and a safer installation, either a countersink or a counterbore hole can be used.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

However, if you require a more secure mounting of your PCB other than conserving space or going for a smoother design, go for counterbore holes. These holes are usually large enough to accommodate socket fixtures, and hence the screws from it will create a more secure attachment. On the other hand, if you want to conserve space, then go for a countersink hole.

Mar 23, 2023 — Sworker Carbide Burr Set Compatible with Dremel 1/8" Shank 10PC Die Grinder Rotary Tool Rasp Bits Wood Carving Accessories Attachments Cutting Burrs Metal ...

A counterbore is more of a cylindrical flat-shaped hole. The hole formed has a flat bottom and allows a screw or fastener with a flat underside to fit. Also, the instrument that is used to create this feature is known as a counterbore. The word will be used interchangeably.

The countersink and counterbore are holes that both require different types of specific fixtures. We tend to confuse a countersink for a counterbore and vice versa, therefore, to understand the difference between the two holes, the similarities and purposes are significant. In this passage, we will focus on the differences of countersink and counterbore and when to use them. Come and check the content below to learn how to effectively fix the PCB without worrying about falling off or loosening the accessories. PCB Instant Quote What are the differences of countersink and counterbore? Before we start looking at the comparison between them, let's highlight what a countersink and a counterbore are. What is Countersink? A countersink is a cone-shaped hole that is bored into a PCB. This hole creates room for a flat head screw or fastener to fit correctly once installed. What is Counterbore? A counterbore is more of a cylindrical flat-shaped hole. The hole formed has a flat bottom and allows a screw or fastener with a flat underside to fit. Also, the instrument that is used to create this feature is known as a counterbore. The word will be used interchangeably. Differences and similarities of them The practice of making a countersunk hole is known as countersinking. Now, a countersunk hole may come in different sizes of angles. It includes the standard sizes of 60, 82, and 90 degrees alongside the less popular 100, 110, and 120 degrees. However, the most frequently used degrees are 82, 90, and 100. While the only angle applicable to a counterbore is a vertical zero degrees, it is just as effective as a countersink. It is important to note that when working with a wooden surface if you fail to countersink first but end up forcing the screw into this surface, not only will the wood's stability and strength be compromised, but your work will consequently be an eyesore. It is because the wood fibers will crack and become dented if not wholly damaged. It is much easier to counterbore a wooden surface; this is because counterboring does not require precision and accuracy in the angles. Also, in a counterbore, all the hole needs are a screw with a flat underside or one with a socket head that can fit with the surface or washer. When to use countersink and counterbore? Now we've established the basics of a counterbore and a countersink hole, let's see when it can be used in a PCB. Although both fixtures are usually for firmer surfaces like wood and metals, it can still be used on a printed circuit board. A PCB, like most circuit boards, has holes, and the method of drilling each hole matters. Some of these holes are screw holes, and it is used as an opening to attach the PCB onto an application. The difference in the type of available screws determines the type of holes you're going to drill onto the PCB, either a countersunk hole or a counterbore hole. Limited Space and Mounting Security If you're running out of space in your device but want additional features on it, as a means to increase the flexibility of your device, you can drill a conical countersink hole into the PCB. This hole is designed to fit a typical screw with a flat head, and it requires more precision than a counterbore hole. Once the screws are flush with the board, it becomes easier to fit the PCB into the required device, either a smartphone or a watch. However, a counterbore, although easy to fabricate, is not usually the best choice for a PCB. It is where the countersink comes in. A countersunk hole keeps the surface of the board smoother, and when done correctly, there is no interference with the arrangement of the board's design. However, if you require a more secure mounting of your PCB other than conserving space or going for a smoother design, go for counterbore holes. These holes are usually large enough to accommodate socket fixtures, and hence the screws from it will create a more secure attachment. On the other hand, if you want to conserve space, then go for a countersink hole. What are the applications of countersink and counterbore? Usually, a printed circuit board is mounted via a screw in a hole. If you need a more evident fixture appearance and a safer installation, either a countersink or a counterbore hole can be used. This drilling process is often done by hand through automated equipment. Drill a counterbore when using a grub screw; the hole creates a perfect foundation for the screw to overlap and fit perfectly into the hole. What are they used for? A countersunk hole in a PCB creates room for a clean installation and is ideal for tight-fitting applications in small devices. PCB countersink applications are found in mobile phones and another small wearable device. A counterbore offers a cylindrical fit to the screw. It is flat bottomed and is cut to allow a socket cap screw to be used. This hexagon socket screw has a hex head and needs to be mounted safely on the PCB. It can be found in washers and other electronic devices that require tight and secure fittings.

PCB Instant Quote What are the differences of countersink and counterbore? Before we start looking at the comparison between them, let's highlight what a countersink and a counterbore are. What is Countersink? A countersink is a cone-shaped hole that is bored into a PCB. This hole creates room for a flat head screw or fastener to fit correctly once installed. What is Counterbore? A counterbore is more of a cylindrical flat-shaped hole. The hole formed has a flat bottom and allows a screw or fastener with a flat underside to fit. Also, the instrument that is used to create this feature is known as a counterbore. The word will be used interchangeably. Differences and similarities of them The practice of making a countersunk hole is known as countersinking. Now, a countersunk hole may come in different sizes of angles. It includes the standard sizes of 60, 82, and 90 degrees alongside the less popular 100, 110, and 120 degrees. However, the most frequently used degrees are 82, 90, and 100. While the only angle applicable to a counterbore is a vertical zero degrees, it is just as effective as a countersink. It is important to note that when working with a wooden surface if you fail to countersink first but end up forcing the screw into this surface, not only will the wood's stability and strength be compromised, but your work will consequently be an eyesore. It is because the wood fibers will crack and become dented if not wholly damaged. It is much easier to counterbore a wooden surface; this is because counterboring does not require precision and accuracy in the angles. Also, in a counterbore, all the hole needs are a screw with a flat underside or one with a socket head that can fit with the surface or washer. When to use countersink and counterbore? Now we've established the basics of a counterbore and a countersink hole, let's see when it can be used in a PCB. Although both fixtures are usually for firmer surfaces like wood and metals, it can still be used on a printed circuit board. A PCB, like most circuit boards, has holes, and the method of drilling each hole matters. Some of these holes are screw holes, and it is used as an opening to attach the PCB onto an application. The difference in the type of available screws determines the type of holes you're going to drill onto the PCB, either a countersunk hole or a counterbore hole. Limited Space and Mounting Security If you're running out of space in your device but want additional features on it, as a means to increase the flexibility of your device, you can drill a conical countersink hole into the PCB. This hole is designed to fit a typical screw with a flat head, and it requires more precision than a counterbore hole. Once the screws are flush with the board, it becomes easier to fit the PCB into the required device, either a smartphone or a watch. However, a counterbore, although easy to fabricate, is not usually the best choice for a PCB. It is where the countersink comes in. A countersunk hole keeps the surface of the board smoother, and when done correctly, there is no interference with the arrangement of the board's design. However, if you require a more secure mounting of your PCB other than conserving space or going for a smoother design, go for counterbore holes. These holes are usually large enough to accommodate socket fixtures, and hence the screws from it will create a more secure attachment. On the other hand, if you want to conserve space, then go for a countersink hole. What are the applications of countersink and counterbore? Usually, a printed circuit board is mounted via a screw in a hole. If you need a more evident fixture appearance and a safer installation, either a countersink or a counterbore hole can be used. This drilling process is often done by hand through automated equipment. Drill a counterbore when using a grub screw; the hole creates a perfect foundation for the screw to overlap and fit perfectly into the hole. What are they used for? A countersunk hole in a PCB creates room for a clean installation and is ideal for tight-fitting applications in small devices. PCB countersink applications are found in mobile phones and another small wearable device. A counterbore offers a cylindrical fit to the screw. It is flat bottomed and is cut to allow a socket cap screw to be used. This hexagon socket screw has a hex head and needs to be mounted safely on the PCB. It can be found in washers and other electronic devices that require tight and secure fittings.

While the only angle applicable to a counterbore is a vertical zero degrees, it is just as effective as a countersink. It is important to note that when working with a wooden surface if you fail to countersink first but end up forcing the screw into this surface, not only will the wood's stability and strength be compromised, but your work will consequently be an eyesore.

If you're running out of space in your device but want additional features on it, as a means to increase the flexibility of your device, you can drill a conical countersink hole into the PCB. This hole is designed to fit a typical screw with a flat head, and it requires more precision than a counterbore hole. Once the screws are flush with the board, it becomes easier to fit the PCB into the required device, either a smartphone or a watch.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 14,000-16,000 (max 24,000) View full product details

A countersunk hole in a PCB creates room for a clean installation and is ideal for tight-fitting applications in small devices. PCB countersink applications are found in mobile phones and another small wearable device.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 12,000-14,000 (max 18,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 12,000-14,000 (max 18,000) View full product details

However, a counterbore, although easy to fabricate, is not usually the best choice for a PCB. It is where the countersink comes in. A countersunk hole keeps the surface of the board smoother, and when done correctly, there is no interference with the arrangement of the board's design.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 14,000-16,000 (max 24,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 14,000-16,000 (max 24,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Also can be used for Dovetail Jigs: Leigh® #140 Materials: Natural woods, composite... View full product details

It is because the wood fibers will crack and become dented if not wholly damaged. It is much easier to counterbore a wooden surface; this is because counterboring does not require precision and accuracy in the angles. Also, in a counterbore, all the hole needs are a screw with a flat underside or one with a socket head that can fit with the surface or washer.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

Now we've established the basics of a counterbore and a countersink hole, let's see when it can be used in a PCB. Although both fixtures are usually for firmer surfaces like wood and metals, it can still be used on a printed circuit board.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Also can be used for Dovetail Jigs: Leigh® #140-8mm shank Materials: Natural woods,... View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

Mortise bits are a must have for cutting out small pockets commonly known as mortises. Featuring a short down shear flute for a finished top edge,... View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 12,000-14,000 (max 18,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

May 30, 2024 — Wendy Boucher - ...

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

This drilling process is often done by hand through automated equipment. Drill a counterbore when using a grub screw; the hole creates a perfect foundation for the screw to overlap and fit perfectly into the hole.

202166 — The Runnable interface has only one method, which is called run(). // Thread action is performed public void run(). Benefits of creating threads ...

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 12,000-14,000 (max 18,000) View full product details

20241028 — Photo by HARVEY DESIGNS on October 28, 2024. May be an image of table.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 18,000-20,000 (max 24,000) View full product details

2023811 — Slot milling, also called groove milling, is a machining process where a rotating cutting tool is used to cut a slot in the workpiece. The slot ...

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

Jan 30, 2024 — End mills are typically classified by their diameter, length, and flute characteristics and are available in a range of standard sizes. The most ...

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

A PCB, like most circuit boards, has holes, and the method of drilling each hole matters. Some of these holes are screw holes, and it is used as an opening to attach the PCB onto an application. The difference in the type of available screws determines the type of holes you're going to drill onto the PCB, either a countersunk hole or a counterbore hole.

The practice of making a countersunk hole is known as countersinking. Now, a countersunk hole may come in different sizes of angles. It includes the standard sizes of 60, 82, and 90 degrees alongside the less popular 100, 110, and 120 degrees. However, the most frequently used degrees are 82, 90, and 100.

Standard Straight bit with plunging capabilities for cutting grooves, dados, mortising, and more. Materials: Natural woods, composite woods, hard plastics Recommended RPM: 16,000-18,000 (max 24,000) View full product details

0086-813-8127573

0086-813-8127573