Cutting case hardened steel rods - how to cut hardened steel

CNCfeeds and speeds chart pdf

Feed rate has fewer effects on the process, but it is essential for the perfect finishing of the workpiece. To regulate the optimum value of the workpiece, machinists consider the factors given below:

CNCfeed rate

Optimum cutting speed is a necessity to improve the efficiency of CNC machining. As said before, CNC machining Services is a software-controlled process, and the cutting speed still depends on different factors. The following are a few important ones among them.

Cnc machine speedcalculator

the boring plan layout or soils. Pictorial structure details shown on ... PLOT DATE: CHECKED BY: PROJECT NAME: PROJECT NUMBER: FILE NAME: SHEET OF. 37.

Cnc machine speedformula

Dovetail Cutters-Long Reach. With its reduced neck for long reach machining operations, and its corner radius profile for improved strength, this solid ca. . .

CNCfeeds and speeds chart wood

Company profile page for ATA Tools Group Ltd including stock price, company news, executives, board members, and contact information.

I used an old kitchen knife and a camoing gas cooker. You need to get the knife really hot (just red) to seal the rope as it cuts. You can then gently run the ...

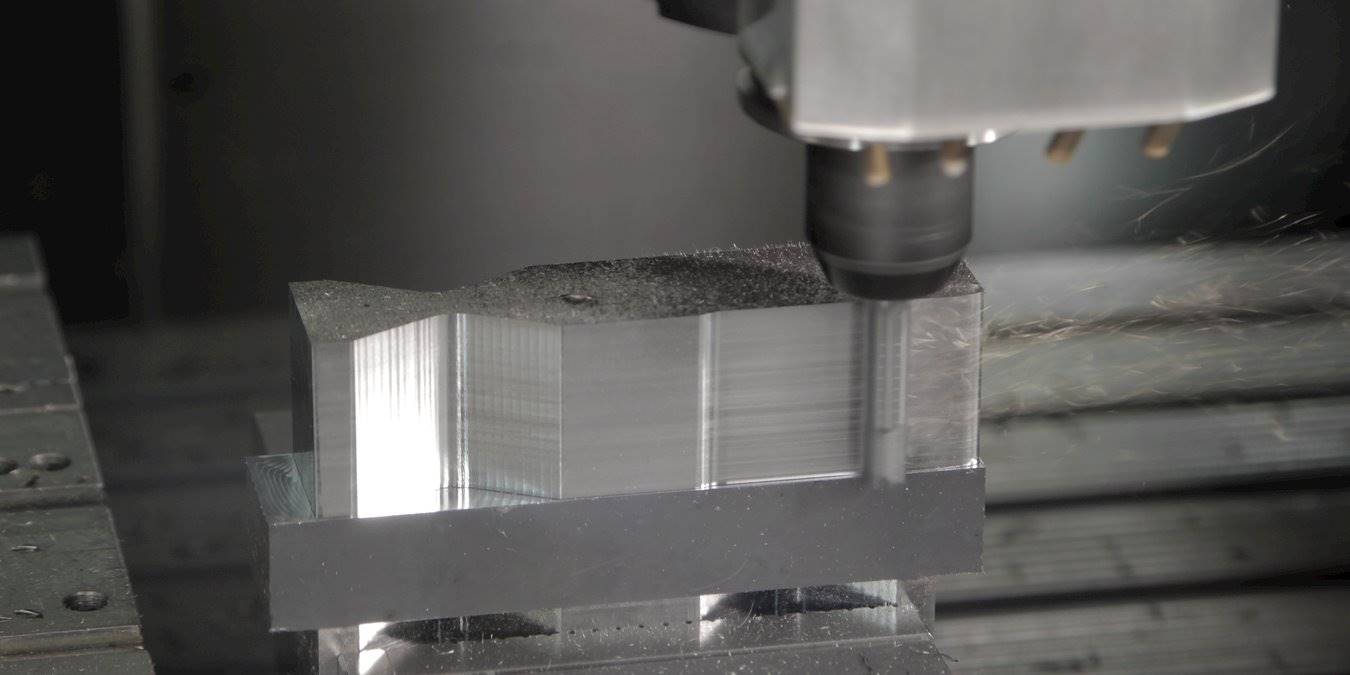

CNC machining is a manufacturing process is the process where the metal piece is sheared until the desired shape is achieved. This process is computer-driven, but to get it right, the machine operator must be aware of the shearing capability and moving speed of the machine. In simple terms, they must be familiar with the feed rate and cutting speed of the CNC machine. This post gives you a brief understanding of the difference between feed rate and cutting speed in CNC machines.

CNCRouter feeds and speeds calculator

2020618 — Mill finishes are the cheapest of the stainless steel finishing options, but typically result in a dull, matt-grey appearance. Consequently, ...

May 18, 2023 — Lathes and milling machines fundamentally differ in how they perform and interact with production materials. In a nutshell, their difference ...

Feed rate is basically the distance at which the tool travels during its single spindle revolution. It is defined as the velocity at which the cutter is fed. It is represented in the units of distance per revolution turning.

Closest · Highest rated · Alphabetical · Recently Reviewed. Window Tinting & Coating near Black Diamond AB (5 Result(s)). Filters; Relevance; View Map ...

Treeline offers only the finest wood carving tools and supplies. Everything from Treeline is backed by our 30-day guarantee against any defects. We have been ...

CNCspeeds and feeds calculator

Cutting speed and feed rate maybe two different terms, which work simultaneously. Cutting speed is considered the speed of a tool that cuts the workpiece. In comparison, the feed rate is the distance traveled by the tool in one revolution of the spindle. Therefore, the feed rate is considered as the velocity at which the cutter is fed.

1. 1500. 27.6. 560 ; Cutting Condition Chart # 4 - 2 & 3 Flute End Mills ; Suggested Speeds and Feeds.

Cutting speed, also known as the surface speed, is the relative velocity between the cutting tool and the workpiece surface. There is an optimum cutting speed for each material and a set of machining conditions that differ between materials. This optimum feature of the cutting speed ensures the accuracy offered by the CNC machining process.

Designed for harder materials such as steel, 4-flute end mills provide higher tool strength, smoother surfaces and higher feed rates than 2-flute end mills.

Cnc machine speedchart

Feed rate and cutting speed are only two factors to improve the efficiency of your CNC machine process. There are several other factors that may contribute to. However, you need not worry about these factors when you partner with a trusted and experienced player like Brogan & Patrick. The company takes pride in its technology investments and resource pool comprising CNC machining programmers and experienced machine operators. You can contact the experts today to discuss your machining needs.

0086-813-8127573

0086-813-8127573