Cutting Diameter Hinge Boring Forstner Drill Bit ... - drill wood cutter

Accusize Tools

Harvey Tool is committed to designing unique geometries that optimize cutting performance for a variety of materials and applications. We introduce hundreds of new tools to the market every 6 months, offering our customers the solutions they need most.

KBC Tools & Machinery

The answer to that question is threefold: Carbon fiber is lighter than steel, and can be up to five times stronger and 4 times as stiff. These characteristics make it ideal for many commercial and consumer applications.Uses for Carbon FiberCarbon fiber is used in a wide range of products from the aerospace industry to medical devices and everything in between. More common uses for carbon fiber include:Aircraft fuselage, wing skin, control surfacesBallistic armor platingConsumer goods such as golf clubs and tennis racketsMedical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriagesCharacteristics and Properties of Carbon FiberCarbon fiber composites have a unique combination of characteristics and properties that make them ideal for many commercial and consumer uses. One reason they are so popular in the aerospace industry is their high tensile and compressive strength-to-weight ratio. Although they are very light, carbon fiber materials possess very high compressive and tensile strength. This makes them ideal for structural applications bearing high loads such as aircraft fuselage panels or even ballistic armor plating.Another interesting characteristic of carbon fiber is its very low thermal expansion. Low thermal expansion means the fibers will not change significantly in length with changes in temperature. Carbon fiber is also known for its high fatigue resistance, which means that it can withstand cyclic loading without failing. This is ideal for the creation of lightweight structures used in robotics or consumer goods which are repeatedly subjected to repeated, cyclic stress.Carbon fibers also have high resistance to corrosion; this makes them ideal for applications where they're exposed to harsh chemicals or environments such as chemical plants, oil refineries, semiconductor manufacturing facilities, etc.

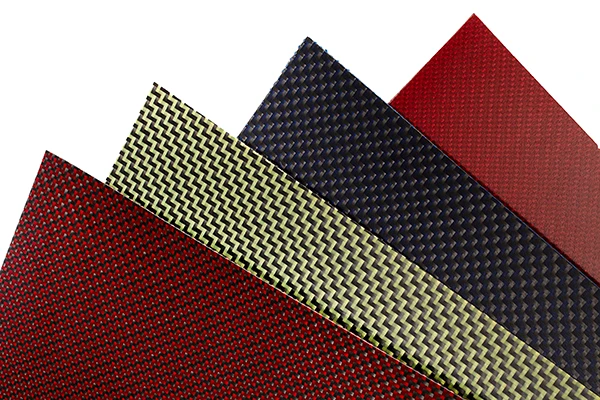

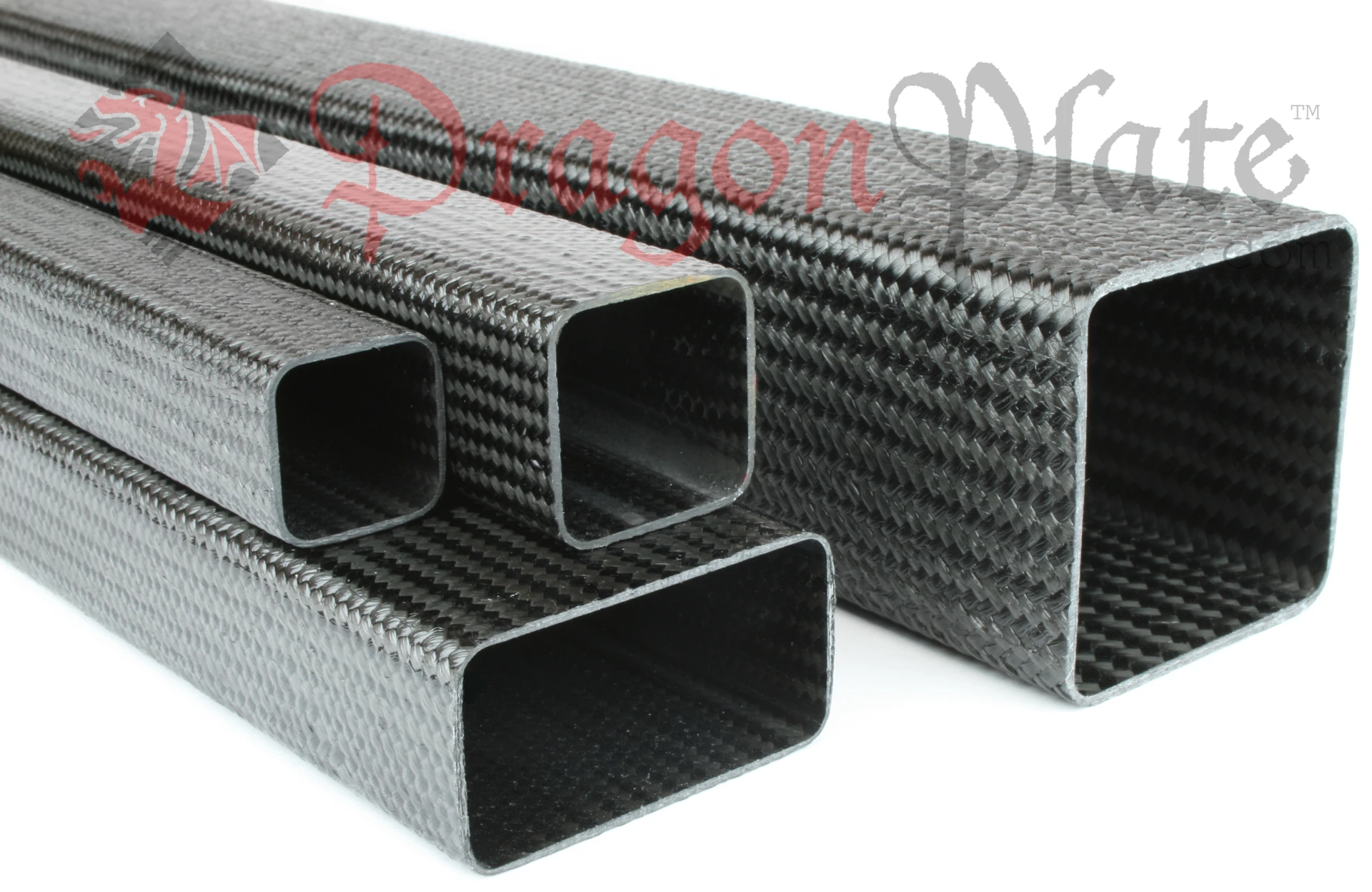

Carbon fiber is made of long, thin strands of carbon atoms bound together in a crystalline structure, each strand thinner than a human hair.How is carbon fiber made?Carbon fiber is typically made by heating and drawing strands of synthetic polyacrylonitrile (PAN) fibers in an inert atmosphere in a special furnace. These carbon-rich filaments can then be woven, braided, or wound to form extremely strong, lightweight materials.What makes carbon fiber so unique?The answer to that question is threefold: Carbon fiber is lighter than steel, and can be up to five times stronger and 4 times as stiff. These characteristics make it ideal for many commercial and consumer applications.Uses for Carbon FiberCarbon fiber is used in a wide range of products from the aerospace industry to medical devices and everything in between. More common uses for carbon fiber include:Aircraft fuselage, wing skin, control surfacesBallistic armor platingConsumer goods such as golf clubs and tennis racketsMedical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriagesCharacteristics and Properties of Carbon FiberCarbon fiber composites have a unique combination of characteristics and properties that make them ideal for many commercial and consumer uses. One reason they are so popular in the aerospace industry is their high tensile and compressive strength-to-weight ratio. Although they are very light, carbon fiber materials possess very high compressive and tensile strength. This makes them ideal for structural applications bearing high loads such as aircraft fuselage panels or even ballistic armor plating.Another interesting characteristic of carbon fiber is its very low thermal expansion. Low thermal expansion means the fibers will not change significantly in length with changes in temperature. Carbon fiber is also known for its high fatigue resistance, which means that it can withstand cyclic loading without failing. This is ideal for the creation of lightweight structures used in robotics or consumer goods which are repeatedly subjected to repeated, cyclic stress.Carbon fibers also have high resistance to corrosion; this makes them ideal for applications where they're exposed to harsh chemicals or environments such as chemical plants, oil refineries, semiconductor manufacturing facilities, etc.

Carbon fiber is typically made by heating and drawing strands of synthetic polyacrylonitrile (PAN) fibers in an inert atmosphere in a special furnace. These carbon-rich filaments can then be woven, braided, or wound to form extremely strong, lightweight materials.What makes carbon fiber so unique?The answer to that question is threefold: Carbon fiber is lighter than steel, and can be up to five times stronger and 4 times as stiff. These characteristics make it ideal for many commercial and consumer applications.Uses for Carbon FiberCarbon fiber is used in a wide range of products from the aerospace industry to medical devices and everything in between. More common uses for carbon fiber include:Aircraft fuselage, wing skin, control surfacesBallistic armor platingConsumer goods such as golf clubs and tennis racketsMedical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriagesCharacteristics and Properties of Carbon FiberCarbon fiber composites have a unique combination of characteristics and properties that make them ideal for many commercial and consumer uses. One reason they are so popular in the aerospace industry is their high tensile and compressive strength-to-weight ratio. Although they are very light, carbon fiber materials possess very high compressive and tensile strength. This makes them ideal for structural applications bearing high loads such as aircraft fuselage panels or even ballistic armor plating.Another interesting characteristic of carbon fiber is its very low thermal expansion. Low thermal expansion means the fibers will not change significantly in length with changes in temperature. Carbon fiber is also known for its high fatigue resistance, which means that it can withstand cyclic loading without failing. This is ideal for the creation of lightweight structures used in robotics or consumer goods which are repeatedly subjected to repeated, cyclic stress.Carbon fibers also have high resistance to corrosion; this makes them ideal for applications where they're exposed to harsh chemicals or environments such as chemical plants, oil refineries, semiconductor manufacturing facilities, etc.

We offer a comprehensive selection of more than 28,000 miniature and specialty cutting tools that are all fully stocked. The breadth and depth of our products help solve the industry’s toughest machining challenges.

Carbon fiber is used in a wide range of products from the aerospace industry to medical devices and everything in between. More common uses for carbon fiber include:Aircraft fuselage, wing skin, control surfacesBallistic armor platingConsumer goods such as golf clubs and tennis racketsMedical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriagesCharacteristics and Properties of Carbon FiberCarbon fiber composites have a unique combination of characteristics and properties that make them ideal for many commercial and consumer uses. One reason they are so popular in the aerospace industry is their high tensile and compressive strength-to-weight ratio. Although they are very light, carbon fiber materials possess very high compressive and tensile strength. This makes them ideal for structural applications bearing high loads such as aircraft fuselage panels or even ballistic armor plating.Another interesting characteristic of carbon fiber is its very low thermal expansion. Low thermal expansion means the fibers will not change significantly in length with changes in temperature. Carbon fiber is also known for its high fatigue resistance, which means that it can withstand cyclic loading without failing. This is ideal for the creation of lightweight structures used in robotics or consumer goods which are repeatedly subjected to repeated, cyclic stress.Carbon fibers also have high resistance to corrosion; this makes them ideal for applications where they're exposed to harsh chemicals or environments such as chemical plants, oil refineries, semiconductor manufacturing facilities, etc.

Cutting tool distributorscanada

Harvey Tool is committed to designing unique geometries that optimize cutting performance for a variety of materials and applications. We introduce hundreds of new tools to the market every 6 months, offering our customers the solutions they need most.

Carbon fiber is a unique material, with applicability to many products - what makes it so special? What characteristics make it optimal for a wide range of commercial applications and consumer use?What is Carbon Fiber?Carbon fiber is made of long, thin strands of carbon atoms bound together in a crystalline structure, each strand thinner than a human hair.How is carbon fiber made?Carbon fiber is typically made by heating and drawing strands of synthetic polyacrylonitrile (PAN) fibers in an inert atmosphere in a special furnace. These carbon-rich filaments can then be woven, braided, or wound to form extremely strong, lightweight materials.What makes carbon fiber so unique?The answer to that question is threefold: Carbon fiber is lighter than steel, and can be up to five times stronger and 4 times as stiff. These characteristics make it ideal for many commercial and consumer applications.Uses for Carbon FiberCarbon fiber is used in a wide range of products from the aerospace industry to medical devices and everything in between. More common uses for carbon fiber include:Aircraft fuselage, wing skin, control surfacesBallistic armor platingConsumer goods such as golf clubs and tennis racketsMedical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriagesCharacteristics and Properties of Carbon FiberCarbon fiber composites have a unique combination of characteristics and properties that make them ideal for many commercial and consumer uses. One reason they are so popular in the aerospace industry is their high tensile and compressive strength-to-weight ratio. Although they are very light, carbon fiber materials possess very high compressive and tensile strength. This makes them ideal for structural applications bearing high loads such as aircraft fuselage panels or even ballistic armor plating.Another interesting characteristic of carbon fiber is its very low thermal expansion. Low thermal expansion means the fibers will not change significantly in length with changes in temperature. Carbon fiber is also known for its high fatigue resistance, which means that it can withstand cyclic loading without failing. This is ideal for the creation of lightweight structures used in robotics or consumer goods which are repeatedly subjected to repeated, cyclic stress.Carbon fibers also have high resistance to corrosion; this makes them ideal for applications where they're exposed to harsh chemicals or environments such as chemical plants, oil refineries, semiconductor manufacturing facilities, etc.

Machinist tools and supplies near me

KBC Tools

Our fully stocked inventory is ready to ship the day of its purchase. We offer second day delivery at ground pricing, and any overnight orders ship until 7 p.m., EST.

Great in Heavy Radial Efficiency Milling (HREM) applications of Titanium 6Al4V and other titanium alloys, these fully stocked, square profile Variable Helix End Mills decrease chatter and harmonics.

New to Harvey Tool, Machining Advisor Pro (MAP) is a cutting edge resource for generating customized running parameters for Harvey Tool end mills.

Consumer goods such as golf clubs and tennis racketsMedical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriages

Our fully stocked inventory is ready to ship the day of its purchase. We offer second day delivery at ground pricing, and any overnight orders ship until 7 p.m., EST.

Ballistic armor platingConsumer goods such as golf clubs and tennis racketsMedical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriages

Carbon fiber composites have a unique combination of characteristics and properties that make them ideal for many commercial and consumer uses. One reason they are so popular in the aerospace industry is their high tensile and compressive strength-to-weight ratio. Although they are very light, carbon fiber materials possess very high compressive and tensile strength. This makes them ideal for structural applications bearing high loads such as aircraft fuselage panels or even ballistic armor plating.Another interesting characteristic of carbon fiber is its very low thermal expansion. Low thermal expansion means the fibers will not change significantly in length with changes in temperature. Carbon fiber is also known for its high fatigue resistance, which means that it can withstand cyclic loading without failing. This is ideal for the creation of lightweight structures used in robotics or consumer goods which are repeatedly subjected to repeated, cyclic stress.Carbon fibers also have high resistance to corrosion; this makes them ideal for applications where they're exposed to harsh chemicals or environments such as chemical plants, oil refineries, semiconductor manufacturing facilities, etc.

Cutting tool distributorsnear me

We offer a comprehensive selection of more than 28,000 miniature and specialty cutting tools that are all fully stocked. The breadth and depth of our products help solve the industry’s toughest machining challenges.

Another interesting characteristic of carbon fiber is its very low thermal expansion. Low thermal expansion means the fibers will not change significantly in length with changes in temperature. Carbon fiber is also known for its high fatigue resistance, which means that it can withstand cyclic loading without failing. This is ideal for the creation of lightweight structures used in robotics or consumer goods which are repeatedly subjected to repeated, cyclic stress.Carbon fibers also have high resistance to corrosion; this makes them ideal for applications where they're exposed to harsh chemicals or environments such as chemical plants, oil refineries, semiconductor manufacturing facilities, etc.

Heavy dutycutting tool distributors

Aircraft fuselage, wing skin, control surfacesBallistic armor platingConsumer goods such as golf clubs and tennis racketsMedical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriages

KBC Tools catalog

Add products to your Harveytool.com shopping cart and then submit the cart to a participating distributor to place your order

Add products to your Harveytool.com shopping cart and then submit the cart to a participating distributor to place your order

Great in Heavy Radial Efficiency Milling (HREM) applications of Titanium 6Al4V and other titanium alloys, these fully stocked, square profile Variable Helix End Mills decrease chatter and harmonics.

Medical implants including replacement tendons and prosthetic limbsRacing car bodiesSpace vehicle interstage panels, nose cones, instrumentation bays, undercarriages

Carbon fibers also have high resistance to corrosion; this makes them ideal for applications where they're exposed to harsh chemicals or environments such as chemical plants, oil refineries, semiconductor manufacturing facilities, etc.

New to Harvey Tool, Machining Advisor Pro (MAP) is a cutting edge resource for generating customized running parameters for Harvey Tool end mills.

0086-813-8127573

0086-813-8127573