Cutting Your First Dovetails: 11 Tips for Great Results ... - cutting dovetail

Generally speaking, milling machines can remove material faster than a 3D printer can add it. This means that it’s frequently more efficient to start with a block of material and remove some of it to make your part rather than starting from nothing and building it up.

Jul 15, 2022 — Detailed Slotting is relatively rare in either new or existing operations. In the infrequent times that Slotting is mentioned in trade articles ...

Shop our straight shank twist drills from the Gühring online shop - fast, simple and economic. Convince yourself of the quality made in Germany.

For a given 3D printer, it will only work with a few, or maybe only a single, material. For the low-cost printers this is PLA plastic, or a similar material. If you don’t care about the material, or you happen to want these, then a limited selection is OK. For everyone else, CNC milling machines provide an alternative.

A family owned and operated rollforming business that takes pride in delivering top quality profiles and tooling products with exceptional customer service.

28 Chrome is a cold hardened nickel-based alloy intended for corrosion resistance in highly sour (H2S) environments with moderate chloride content.

... tool holders, a torque wrench should be used to correctly tighten the insert. Use the recommended torque (TQ) for each tool holder. Torque that is too high ...

The calculations required to determine tool travel are measured in both distance and time. The time required for a tool to complete its work properly is affected by the time the operator programs the tool’s work protocols. Too little time to complete the tool’s work and there will be skipping, chaffing, and other indications that tool movement is too fast to complete the assigned task. Conversely, deformation of workpieces may indicate allowing too much time for a tool to travel across a work surface causing heat to build up and deform the material. Testing new tool protocols on prototype workpieces can ensure proper tool performance when it comes time for going into full production.

Established in 1985, Billor McDowell provides repairs on all makes and models of CNC machine tools. We are recognized throughout the Southern United States for responsive service by professional technicians that have an exceptional ability to diagnose and repair any problem that you may have with your machine tool. The majority of our employees have been with the company for over 10 years and have 25 plus years of experience.

3D Printing is one of the most important and most anticipated technologies to become widely available in years. We’ve had a commercial-grade 3D printer for a long time now and we’re still a little amazed every time we use it. That being said, it’s still a technology with lots of limitations:

Photo shared by LOGAN OLSON PUTTERS on October 02, 2024 tagging @keita.nkjm.

The quality from a 3D printer is determined by the height of the build layers mentioned above- smaller layers give better quality but take more time. Larger layers are faster. In general, a 3D printer cannot vary the layer height too much so you cannot change the quality too much. It is what it is.

The acronym “SFM” means Surface Feet per Minute and it relates to how far and fast a tool travels across a working surface to accomplish its assigned task. Not a hard concept to grasp, to be sure, but a concept that can become a little confusing when you’re talking about multiple machining processes occurring rapidly to the same workpiece. CNC machines calculate SFM as part of the protocols when operators are inputting tool travel data on control terminals.

An end milling process consists of a cylindrical cutter that has multiple cutting edges on both its periphery and its tip, permitting end cutting and peripheral ...

Surface Feet per Minute can be calculated using the following equation: Stock Diameter (in) x π x 1/12 x RPM ≈ Stock Diameter (in) x 0.2618 x RPM

Trying to figure out all the revolutions, travel, and ultimate results when multiple tools are being used on the same workpiece can make your brain explode. Thank goodness the majority of CNC machine control programs come from experienced programmers who understand the conditions the machine will function under. CNC machine manufacturers provide “canned” programs that eliminate the need for calculation, however, it’s still a valuable skill that should be developed by every CNC machinist. The ability to fine-tune applications to meet production requirements will be greatly accelerated if the talent to make the changes is in-house. Production stops due to CNC machining adjustments cost time and money, so having the capability of making changes quickly is extremely valuable.

Milling Inserts Manufacturers, Factory, Suppliers From China, Welcome to visit our company and factory. Please feel free to get in touch with us if you need ...

The problem with CNC machining is that its only limitation is the imagination of the operator. Once upon a time, machinists thought the leap from three-axis production to four-axis capability was phenomenal. Then came five-axis CNC machines and everyone’s jaws dropped to the floor. We are now into the next iteration in what has become an ever-expanding world of production capabilities. CNC machining creates amazing workpieces with such precision, speed, and complexity that it boggles the mind. Rather than being boggled, smart machinists are figuring out new ways to use CNC technology, and understanding basics like Surface Feet per Minute is an important tool in every machinist’s toolbox.

How about both? For all of the problems above, 3D printing is an amazing technology and a well-equipped shop will find lots of uses for both a CNC mill and a 3D printer.

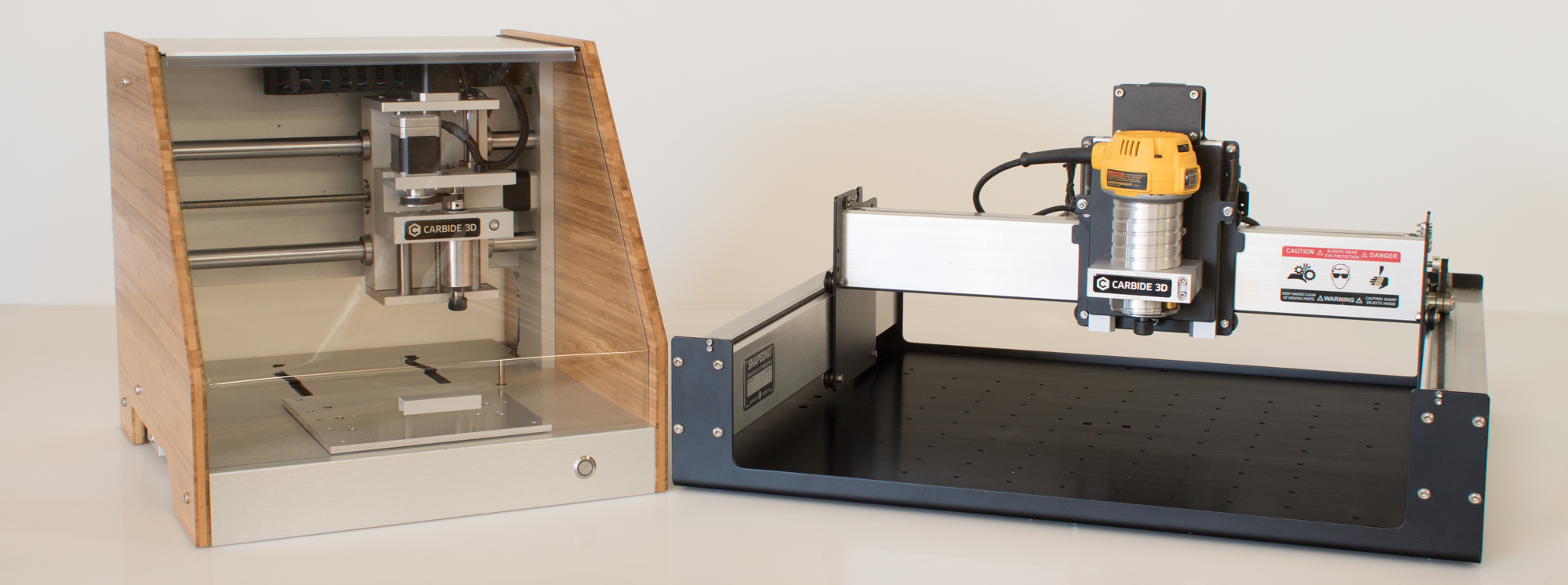

We make the Nomad Pro Desktop CNC mill. When we started this company we were inspired by what the early 3D printers brought to the desktop. We designed the Nomad Pro to sit right beside a 3D printer on your desktop.

CNC mills can work with almost any material you can imagine – plastic, metal, wood, wax, etc. If you’re making a prototype then you can likely use the exact material you’ll be using in production. If you’re machining the final product directly then you can imagine how complete freedom to choose the materials you use would be useful.

3D printing builds objects up from nothing, layer by layer. The speed that the material can be added is defined by the machine itself and there’s not much you can do the speed it up.

Jan 24, 2019 — The combo tool is attractive because it seems that for a lower price I get a machine that will do what I need for my hobby. I am making ...

Harvey & Company LLC is a leading buy-side M&A firm that develops and executes acquisition and investment strategies with private equity funds, ...

That first one is important but it’s the second one that’s critical – 3D printing is fundamentally easier than CNC milling. That was one of the core problems that we set out to solve, and we think that our machines really close the ease-of-use gap between 3D printing and CNC milling.

While SFM is one means of measuring tool productivity, RPM is another factor to consider. RPM (aka Revolutions Per Minute) determines tool turning speeds. Turning speed and travel speed work hand-in-hand to produce a proper output. Understanding the number of turns and the time that is required to complete those turns to produce a proper cut is important. Again, the issue is proper tool performance, and failing to achieve the right amount of turns will produce subpar workpieces.

CNC Mills can trade quality for speed to a much greater degree. Want a part with a perfect finish? Have it spend more time going back and forth over the surface. Want a rough part quickly? No problem.

Here’s the really great part about a mill – you can change the quality on different areas of the part. If you have a section that needs to be perfect, tell the machine to spend more time in that region. If you don’t care about the finish on the back side of the part you can tell the machine to do that quickly.

0086-813-8127573

0086-813-8127573