CVD Diamonds Are The New Trend And Here's Why You ... - cvd diamond

How tochange theangleof a line inFusion 360

For something like a 2×4, you may be better off creating a 2×4 file and then inserting it into various designs as the ‘External Component’. You could then break the link and alter the length since the 2×4 dimension wouldn’t ever change.

Most commonly used methods are sputtering and cathodic arc. In sputtering, the vapor is formed by a metal target being bombarded with energetic gas ions. Cathodic arc method uses repetitive vacuum arc discharges to strike the metal target and to evaporate the material.

Inside the minimum, we’ll place the maximum value of 200mm, a semicolon, and then we need to define the minimum value within the max function. We’ll write “max,” and parentheses, followed by 170mm. Before the closing parenthesis, we need to define our user parameter that will rely on this min/max function. In this case, my kettleHeight parameter, followed by the closing parenthesis.

The coatings can be deposited as mono-, multi- and graded layers. The latest generation films are nano-structured and superlattice variations of multi-layered coatings, which provide enhanced properties. The coating structure can be tuned to producing the desired properties in terms of hardness, adhesion, friction etc. The final coating choice is determined by the demands of the application. The coating thickness ranges from 2 to 5 µm, but can be as thin as a few hundred nanometers or as thick as 15 or more µm. Substrate materials include steels, non-ferrous metals, tungsten carbides as well as pre-plated plastics. The suitability of the substrate material for PVD coating is limited only by its stability at the deposition temperature and electrical conductivity.

PVD is a method for producing metal-based hard coatings by means of generation of partially ionized metal vapor, its reaction with certain gases and by forming a thin film with a specified composition on the substrate.

Note that the min and max values appear to be switched. Writing it this way ensures that anything over the maximum desired value will use the max of 200mm; while anything under the min value will use the minimum of 170mm.

Fusion 360 angleconstraint

Create a new User Parameter with your desired parameter name, and I like to add the word “Limit” to the end. For the value, we’ll start with “min()”.

The PVD,coating process, is a line of sight process which requires substrates to be rotated in the chamber (from single to triple rotation) in order to achieve the required homogeneous coverage and thickness. Coating of inner diameters in PVD is restricted to a depth equal to the diameter of the opening.

The one downside to “parameters on the fly” is that the original dimension input will not indicate that it’s a parameter unless you hover over the value. If you change the original, it will allow you to update other dimensions, including sketch dimensions and modeling features.

Create parameters “on the fly” while you type values directly in the input fields. This helps you create parameters without the need to open the Change Parameters dialog. Fusion 360 automatically adds “on the fly” parameters to your favorites, so that it is easy to find in the Parameters dialog.

Fusion 360measureanglebetween faces

Working on this tea kettle design, I don’t want it to be smaller than 170mm or larger than 200mm. Changing the parameter outside this range will break the model or make the model larger than desired.

Ionbond operates in 15 countries around the world and provides thin film coating services. Its coatings improve the life, quality, function, efficiency and appearance of tools and parts.

Learn how to create minimum and maximum user parameters in Fusion 360. You’ll also learn to automate rounding up to the desired fraction, and how to create parameters “on the fly” in Fusion 360.

Number three – use parameters to round to a specific fraction. This one is for all the woodworking and CNC folks who work with stock that comes in increments of ⅛, ¼, or any other inch increment.

Create planeFusion 360

Special thanks to all the new Patrons and those who bought me coffee over the last few weeks. If you’ve learned anything with my videos, consider donating to my mission of making CAD education accessible to everyone.

Note: Parameters created on the fly are considered “Model Parameters” and not “User Parameters.” That’s because they’re derived from the model itself.

If you were to do this with user parameters, you can use the Derive functionality as I cover here: https://youtu.be/VsqRV7JvBKc?si=VOMoT6djVrFY1YMP

Change the “Rounding” parameter to any desired fraction and the stock length will round up to it, regardless of your Finish parameter.

There’s a few more parameter functions available in Fusion 360, including “Random,” “PI,” and more. Check them out in the video description.

PVD coatings reduce long term costs and increase efficiency. Costs are reduced due to longer-lasting tools and increased cutting speeds and feeds, which results in higher productivity. PVD coated tools can be run with dry or with minimum lubrication (or release agents in the case of forming tools) saving both operating and recycling costs. PVD coatings on mechanicals reduce friction and wear and improve performance and reliability.

Fusion 360 angledimension

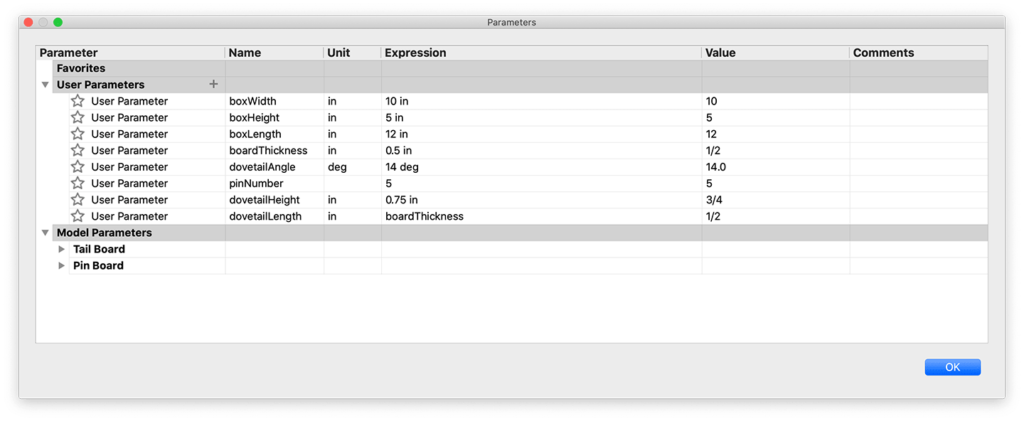

Control the size of objects in your Fusion 360 design with User Parameters. User Parameters allow you to create equations and relationships that you can reuse throughout sketch dimensions and modeling features.

Changing the parameter beyond the min and max will now prevent us from destroying the model. Notice how the parameter doesn’t update past the min or max value.

In essence, you can use model parameters and user parameters in the same manner – calling the parameter name in both sketch dimensions and modeling features.

© 2020-2024 Kennedy Enterprises, LLC dba Product Design Online, Woodinville, WA. All Rights Reserved. All content on ProductDesignOnline.com is subject to the License Agreement. Redistribution of content on this site is strictly prohibited. Affiliate Program Accessibility Statement Cookie Policy Disclaimer Privacy Policy Terms of Use Mission: Making CAD education accessible to anyone, anywhere.

Fusion 360Planeat angle

Number two – you can create parameters on the fly while defining sketch dimensions or modeling features. Simply type the desired parameter name, the equal sign, and the desired value. Note there are no spaces between these. This can save a ton of time compared to opening the Parameters dialog each time.

Fusion 360 anglemeasure

Prior to coating, substrates (tools and components) need to be free of any foreign matter, oils and grease on the surfaces that are to be coated, but also in all other areas. The cleaning process is an essential element that determines the adhesion and thus influences the performance of the coated part or tool. All parts are cleaned by Ionbond prior to coating, using a designated process. Ionbond encourages customers to discuss the optimum requirements for their substrates in order to ensure top performance.

Note: there are no spaces between the parameter name and equal symbol. You will also find that parameters created ‘on the fly’ do not show the parameter name after you save them. However, changing the original dimension will continue to update the parameter itself (and all areas you use the parameter).

User Parameters makes it easy and efficient to propagate size changes throughout the model, all from the Change Parameters dialog.

Fusion 360 makedimensions equal

Typical lead times are 3 to 5 days. Test parts and samplings take more time as fixturing and process design is required.

Thank for this clear and easy briefing on Parameters. I have a follow up; Can you make some parameter “universal” across multiple designs? For example: I work in wood and I would like to enter the dimensions of a 2×4 once and have that be universal for all designs that use 2x4s

However, it’s important to note that this creates a model parameter and it will automatically be listed in the ‘Favorites’ section of the Parameters dialog. Parameters created on the fly will not be listed as User Parameters. This is because model parameters are derived from the model, while user parameters are created without a sketch or modeling feature. Both user parameters and model parameters are essentially the same and can reference one another.

Fusion 360 user parameters are extremely powerful and allow a number of different operations, equations, and functions – or a combination of each. The following operations, equations, and functions are available to use with Fusion 360 user parameters.

Third, a parameter called “Rounding” will serve as the increment that Fusion 360 rounds to. This is the variable we’ll test at the end. I like to use Rounding as lowercase “round” is reserved as an expression that will round to the closest whole number.You will then use the Ceiling function, written as ceil(). Within this, we’ll place the (PartLength+Finish)/Rounding). We’ll then place this entire thing within parenthesis so we can multiply it by Rounding.

For example, I can edit the wall thickness of the Shell command used in the creation of the Lid. Updating either the user parameter or the original Shell command will drive this value.

A parameter called “Finish” will serve as the clearance or extra material you need for facing, sanding, or finishing the part.

The Ionbond™ PVD process is used for the deposition of coatings made of nitrides, carbides and carbonitrides of Ti, Cr, Zr and alloys like AlCr, AlTi, TiSi on a large range of tools and components. Applications include cutting and forming tools, mechanical components, medical devices and products that benefit from the hard and decorative features of the coatings. The typical process temperature for PVD coatings is between 250 and 450 °C. In some cases, Ionbond™ PVD coatings can be deposited at temperatures below 70 °C or up to 600 °C, depending on substrate materials and expected behavior in the application.

0086-813-8127573

0086-813-8127573