CVE-2023-48308 Detail - NVD - 48308

Destiny toolcustomer login

Destiny toolfor sale

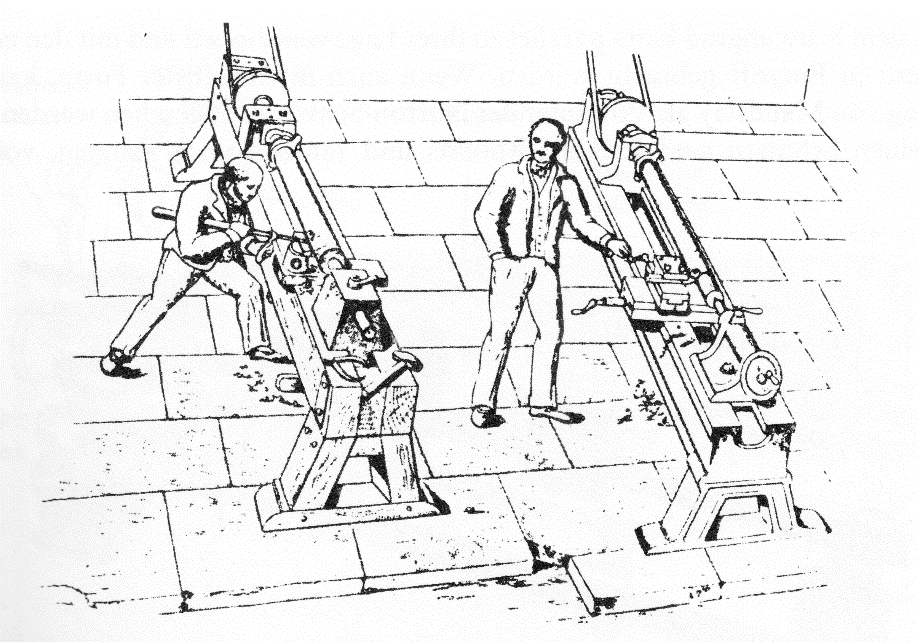

Lathe machines are commonly used in metalworking, metal spinning, wooding and glazing. Lathe machine includes actions such as sand, cutting, kneeling, drilling, and distortion of the tools employed to create symmetrical substances about sand axes. Some of the most common types of the lathe machine:

A Lathe Machine is one of the most important material removal methods in the technology of manufacturing. It is basically a collection of material-working processes that involve other processes. A lathe is a machine tool used principally for shaping pieces of metal and wood or other materials by causing the work piece to be held and turned by the lathe while a tool bit is advanced into the work on the cutting function. A powerful machine that is useful to shape wood in machining is the lathe machine.

Destiny2 tools

The lathe was very important to the Industrial radiancy. It is known as the mother of machine tools in industries, as it was the first machine tool that signs to the invention of other machine tools. The first fully equipped, all-metal slide rest lathe was invented by Jacques de Vaucanson around 1751.

DestinyViper

Headstock The headstock contains the high precision bearings which hold the horizontal axle, more commonly known as the spindle.

Spindle This is a hollow horizontal axle with interior and exterior threads on the inboard by which the woodworking pieces can be mounted on.

Select Accept to consent or Reject to decline non-essential cookies for this use. You can update your choices at any time in your settings.

Destiny toolcatalog

Tool Rest A horizontal area in line with the spindle and the tailstock from which hand tools are to control it and lever into the work pieces.

LinkedIn and 3rd parties use essential and non-essential cookies to provide, secure, analyze and improve our Services, and to show you relevant ads (including professional and job ads) on and off LinkedIn. Learn more in our Cookie Policy.

In today's manufacturing world it's all about who can produce to most number of quality parts, in spec and in tolerance at the end of the work day. If you do that, you and your company make money and beat the competition. At Destiny Tool we believe that in order to be a top performer you have to pick out your niche and then constantly improve upon it. Diamondback Rougher - We began development of our unique aluminum and other non-ferrous roughing tools in the early 1990's. While most cutting tool manufacturer's design tools to be used at 1 diameter depth of cut, ours tool design is based upon a 2 diameter depth of cut. That translates into a 3 flute, 3/4 diameter end mill that can cut a slot 1.5" deep at at 14,000 RPM and up to a .040" chip load per tooth. Viper DVH - Since not every company has the RPM or need for high Metal Removal Rates (MRR) the Viper is the first tool of choice for aluminum and non-ferrous materials. It can both rough and finish and provides a unique method of chip evacuation due to it's PATENTED double variable helix design. Unlike many companies, we don't just offer a stub, standard and long length: Our selection is much deeper and more unique: As an example we have a 1/2" diameter tool with an 6" overall length (OAL) in full fluted and neck relieved versions called our LBS or "length below shank" design. Raptor - This group of tools evolved from our Cobra and Python end mills designed for high temperature alloy machining in materials such as Stainless Steel & Titanium. As you know, these softer gummy materials are often considered "difficult to machine" because of material buildup and and thermal expansion rates. Our unique designs in both our Raptor DVH and our Raptor DVH 3/6 not only provide exceptional material removal rates & chip evacuation but most of the heat is removed with the chip: We induce less heat in the base material which translates into better finish, faster part production AND longer tool life "in-the-cut".

A lathe is an ancient tool, with Weak evidence for its survivor at a Mycenaean Greek site, dating back as far as the 13th or 14th century BC.

0086-813-8127573

0086-813-8127573