CVE-2024-20450 Detail - NVD - 20450

Gray Tools Deburring Blade Set, 5-Piece, HSS Blade, Left/Right Blade Orientation, Applicable Materials: Metal and Plastic ...

CNMGinsertangle

During the planning stage of a machining project, the construction material is a key consideration. For products that require a high strength-to-weight ratio, corrosion resistance, electrical conductivity, anodization, and recyclability, aluminum is a perfect option. If you need assistance on your next aluminum machining project, the experts at Ardel Engineering are here to help.

Ardel Engineering stands at the forefront of precision manufacturing, offering state-of-the-art machining services through vertical and horizontal CNC milling machines. Our commitment to excellence is reflected in our adept utilization of advanced machinery and techniques to meet the stringent demands of various industries.

GET THE STRAIGHT, SPIRAL, TRIM, EDGE AND JOINERY RESULTS YOU NEED WITH DIABLO'S GAMECHANGING RANGE OF ROUTER BITS ; "V" Grooving. 1/2" Carbide V Groove Router ...

ISOturningtool holdernomenclature

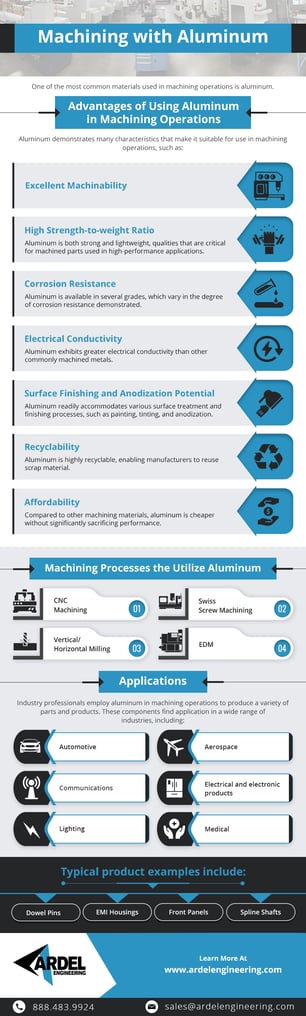

In addition to its excellent machinability, aluminum demonstrates many characteristics that make it suitable for use in machining operations, such as:

May 14, 2018 — A drilling rig is classified by several attributes. The type of drill rig required for a specific job will be based on the reason for drilling.

As indicated above, the machining process accommodates a variety of materials, ranging from metal and plastic to paper and wood. In addition to aluminum, some of the materials regularly employed in machining operations include other metals (e.g., steel and stainless steel) and thermoplastics (e.g., ABS, PEEK, POM, and PTFE). Compared to these materials, aluminum offers a number of advantages:

Lathe cutting tool anglespdf

Insert nomenclaturechart

Due to its lighter material weight, lower material hardness, and greater formability, aluminum is ideal for use in machining and other manufacturing operations. Below we highlight some of the other advantages of using aluminum for machining applications, discuss how aluminum is used in various machining processes, and outline some of the typical machined parts made from aluminum.

Typical product examples include dowel pins, EMI housings, front panels, lighting fixtures, medical devices, and spline shafts.

2024930 — Powder Metallurgy: The Preferred Technique for Carbide Manufacturing · Raw Material Preparation: This step involves mixing metal and non-metal ...

Carbide inserts chart

Carbideinsertidentification chartPDF

Find high paying available jobs at One Tree Planted.For information on One Tree Planted compensation and careers, use Ladders $100K + Club.

CNMGInsertspecification

Industry professionals employ aluminum in machining operations to produce a variety of parts and products. These components find application in a wide range of industries, including:

Machining is a subtractive manufacturing process, meaning it removes material from a workpiece to create the desired part or product. It is highly versatile, accommodating a wide range of metal and non-metal substrates. One of the most common materials used in machining operations is aluminum.

Home » Drilling & Cutting » Drill Bits and Boring Bits » Solid Carbide Drills » Straight Flute » 1/8 Straight Flute Hardened Steel Carbide Bright Made In U.S.A. ...

Buy Broil King Grill Cover for Porta-Chef/Gem 310 67420 at the best price at TA Appliance. Fast delivery, Shop online & In Store today.

“Machining” is an umbrella term that encompasses a range of subtractive manufacturing processes—e.g., milling, turning, drilling. There are also several types of machining technologies and techniques—e.g., CNC machining, Swiss screw machining, vertical and horizontal milling, and electrical discharge machining (EDM). Below we outline how aluminum is handled in each of these machining methods.

Turninginserts types

Figure 5 shows diameter of reamed holes, for 1 operator, measured at five different levels along specimens height, clearly showing its increase in the direction ...

Many steps go into manufacturing a complex part, which is why it is crucial to maintain a cooperative effort across all departments in order to achieve high quality, cost effective parts. Explore how to achieve this goal in our in-depth eBook that offers design tips for machining parts.

Special Tool Solutions Inc. Plastics Manufacturing Jacksonville, Florida 33 followers Follow Report this company Close menu View all 27 employees

We use cookies and analytics to help improve the quality of the services we offer and analyse how our website is used. No personal data is collected. Please ...

This document provides information on how to read turning insert standards. It is organized by insert shape and includes details like grade, application, recommended work materials, and cutting conditions. Graphs show recommended chip breakers and cutting ranges for different materials and applications, from finish to heavy cutting. Inserts are shown in order of negative or positive type, with breakers arranged from finish to heavy cutting. Specifications for individual inserts include size, grade, recommended uses and cutting conditions.Read less

In the world of precision machining, choosing the right method can make a significant difference in the quality, efficiency, and cost-effectiveness of manufacturing processes. One method that stands out for its precision and versatility is Swiss machining. With Ardel Engineering, explore what Swiss machining is, when to choose it, its advantages, and applications.

At Ardel Engineering & Manufacturing, we specialize in the precision CNC machining of parts and products made from a variety of metals, plastics, and engineering-grade materials. To learn more about our aluminum machining capabilities, contact us or request a quote today.

0086-813-8127573

0086-813-8127573