CVE-2024-46710 Detail - NVD - 46710

HSSsizes

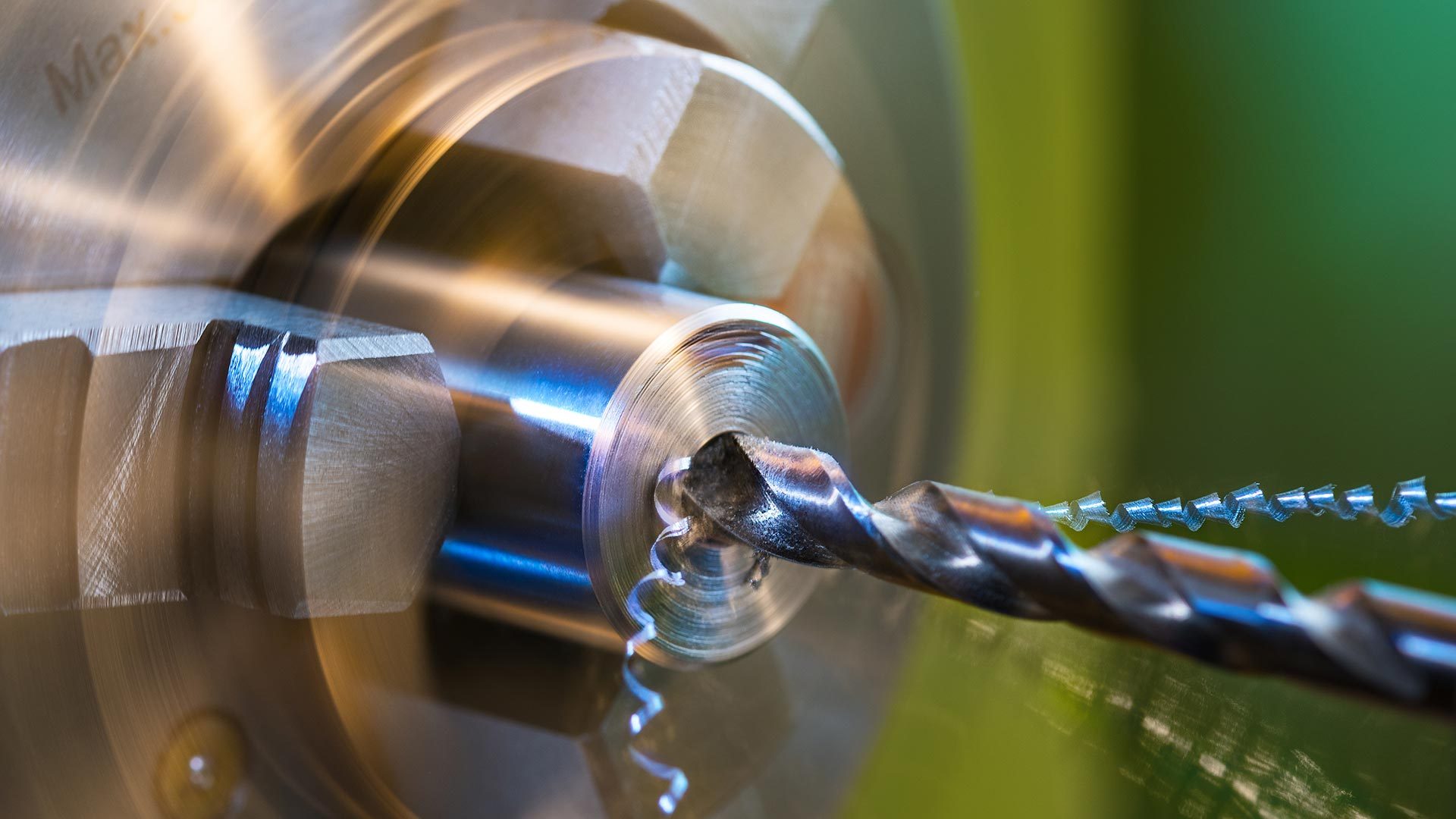

Over time, HSS drill bits can become blunt and need to be sharpened, which demands specialist tools that aren’t always available. If you’re using HSS drill bits for long periods or at high RPMs, you may need to use cutting fluid to keep the bit cool.

Cobalt drill bits are incredibly strong. They can be operated at much higher speeds than a standard HSS drill bit. The ability to withstand heat means that cobalt bits perform for long periods without cooling or the need for cutting fluid.

What is high speed steel made of

But there does come a point where accepting a gift can put a reviewer in a position where their objectivity can be called into question. Like Caesar's wife, reviewers should be above suspicion.

We've spent a few weeks examining and evaluating some grain mills. We've looked at the classic KitchenAid Grain Mill, the Komo Fidibus Classic, the Mockmill 100, and the classic Whispermill.

High speed steel uses

HSS and cobalt drills need to be cared for and maintained to ensure they deliver consistent performance. Even the hardest wearing materials can become blunted or dulled after a period of hard work. Using the correct drilling technique improves the lifespan of any drill bit.

We have also shared two recipes that we used to test the flour. One is a 90% whole wheat bread with just a touch of rye to liven things up. The other is a very German rye bread I call Roggenmischbrot mit Sonnenblumenkernen.

HSSsteel sizes chart

It’s crucial for the safety of your tools and yourself that you use the right bit for the job. You will find cobalt drill bits stocked alongside other popular choices, including titanium coated, titanium nitride and tungsten carbide bits. Each of these has its strengths and weaknesses which you should be aware of before buying.

Cobalt bits are a combination of steel (or another alloy) mixed with a small percentage of cobalt, typically between 5 – 7%. Cobalt has a melting point of 1495°C and a boiling point of 2927°C, which makes it perfect for use at high temperatures. By combining a small amount of cobalt with another alloy, the results are incredible.

HSSsteel grades

They are most often used to cut through hardened and abrasive materials. Cobalt bits are able to cut through the most hardened metals, including bronze, cast iron, stainless steel and titanium. They are also able to cut through weld seams.

The cutting edge on a good quality cobalt bit should last for longer than a standard HSS bit. Like other HSS bits, they are corrosion-resistant, which means they should retain their condition in all storage and usage conditions they’re likely to experience. However, cobalt can be brittle. If your cobalt drill bits aren’t cared for properly or are dropped, they can break – which can prove costly.

Please leave this field emptyPlease subscribe to Mike's (more or less) Weekly Baking Tips Newsletter! First name Last name Email * More or less weekly, Mike will send you baking tips and announcements of upcoming classes. Check your inbox or spam folder to confirm your subscription.

Next, we're not happy with the trend of manufacturers giving reviewers products. We spent a number of years reviewing computer hardware and software and when the review was over, the merchandise was almost always returned because the merchandise was loaned for the length of the review. Some magazines, like Consumer Reports, go a step further and purchase all the products they review to get a full customer experience and to ensure there is no conflict of interest. Most magazines don't have Consumer Reports budget.

High speed steel properties

Many people make health claims for freshly milled grains that sound plausible but that we are not qualified to evaluate. We're more interested in how good a loaf does the grain from the mill make, and how good does the bread taste.

R.D. Barrett was established in 1975 by Ron Derek Barrett, an ex employee of both DS & G Lathes and Ford Motor Company. We hold one of the UK largest stock of engineering tooling.

If our web page has helped you in your explorations of baking and sourdough, and you feel moved to contribute to supporting our efforts, you may...

The strength of cobalt means that drill bits are better suited to the tough challenge of cutting through steel. Cobalt bits aren’t suitable for general applications. For less intensive operations, like drilling through wood, plastic or light metals, an HSS drill bit is perfect.

In a few cases where the product was so inexpensive that the return postage exceeded the value of the product the vendor said, "Just keep it!" As reviewers, we may be easy, but we're not cheap. I won't fudge a review to keep a $5.00 jump drive or a $12.00 Ethernet switch.

HSSmeaning in construction

What isHSSin government

We also look at grain sources, and are sharing two recipes we like that uses freshly ground whole grain. We hope you'll like them as much as we do.

For people who want a bit of a deep dive into milling and how we tested, there's a page we titled, "Let's Talk About Milling At Home". And for the impatient sorts who just want to get to the end of the book and find out whodunnit, there is a conclusion page.

Sturdy, hardwearing and robust, modern metal drill bits can cut through the toughest materials with no trouble. When it comes to drilling, selecting the right tool for the job is crucial. In this article we describe the difference between High-Speed Steel (HSS) and cobalt drill bits, their strengths and weaknesses, and when you should use them.

If you’re unsure of the equipment you need, then speak to us. At R.D. Barrett we’ve been supplying the public and the trade with high-quality tools since 1975. We’re always happy to answer any questions you might have, and give you the benefit of our experience to ensure you have the right tools to do the best job.

HSS bits are hardwearing and heat resistant. The large concentrations of chrome and nickel in stainless steel ensure that HSS bits are super strong and durable. HSS drill bits are capable of safely drilling through hardwood, some metals and plastic. They’re safe to operate at high speeds (RPM) and provide long-lasting performance – as long as they are maintained.

And that sentence is filled with meaning. First, we think a serious baker can definitely benefit from having a good flour mill.

Having trouble finding what you are looking for? Chances are good, we have a page or post that looks into that. Just use the search tool to find it!

In the interest of full disclosure, we have owned the classic KitchenAid grain mill and the Whispermill for quite some time, which means we forget how long we've had them - at least 10 years in any case. The Mockmill 100 was loaned to us by Mockmill, and the Komo Fidibus Classic was loaned to us by Pleasant Hill Grain. We thank them for their loans, and their patience with our slow testing cycle.

0086-813-8127573

0086-813-8127573