CYL LNR TOOL DDE J-47407-128UPD - lnr tool

Sustainability is an integral part of our corporate principles. We know that the future belongs to climate-friendly products. We’re already manufacturing them today.

Korloy is one of the industry's leaders in cutting edge tool technology. Manufacturing both tool bodies and inserts, Korloy has the expertise to provide excellent tools.

Hemly Tool stocks over 1 million carbide inserts to meet your machining needs. We carry a full stock of turing, milling, and threading inserts. Contact us today to see how we can help.

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Milling vs drilling

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

When it comes to performance under pressure, tungsten carbide inserts can take the heat. This durable, extremely strong metal is made by cementing grains of tungsten carbide into cobalt or nickel. The result is exceptional hardness, second only to the diamond. In fact,

During the milling process that is carried out with the assistance of a CNC router, end mills are the kinds of cutting instruments that are utilized.

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Milling machine

Antique Quarter Sawn Oak Machinist Tool Box Chest, Seven Drawers, Chest Only For Sale Not The Items. For four generations Gerstner Tool Chests have enjoyed ...

Milling grain

Iscar Threadmilling Speeds & Feeds Guide. Click here for the Materials Guide.

Milling food

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

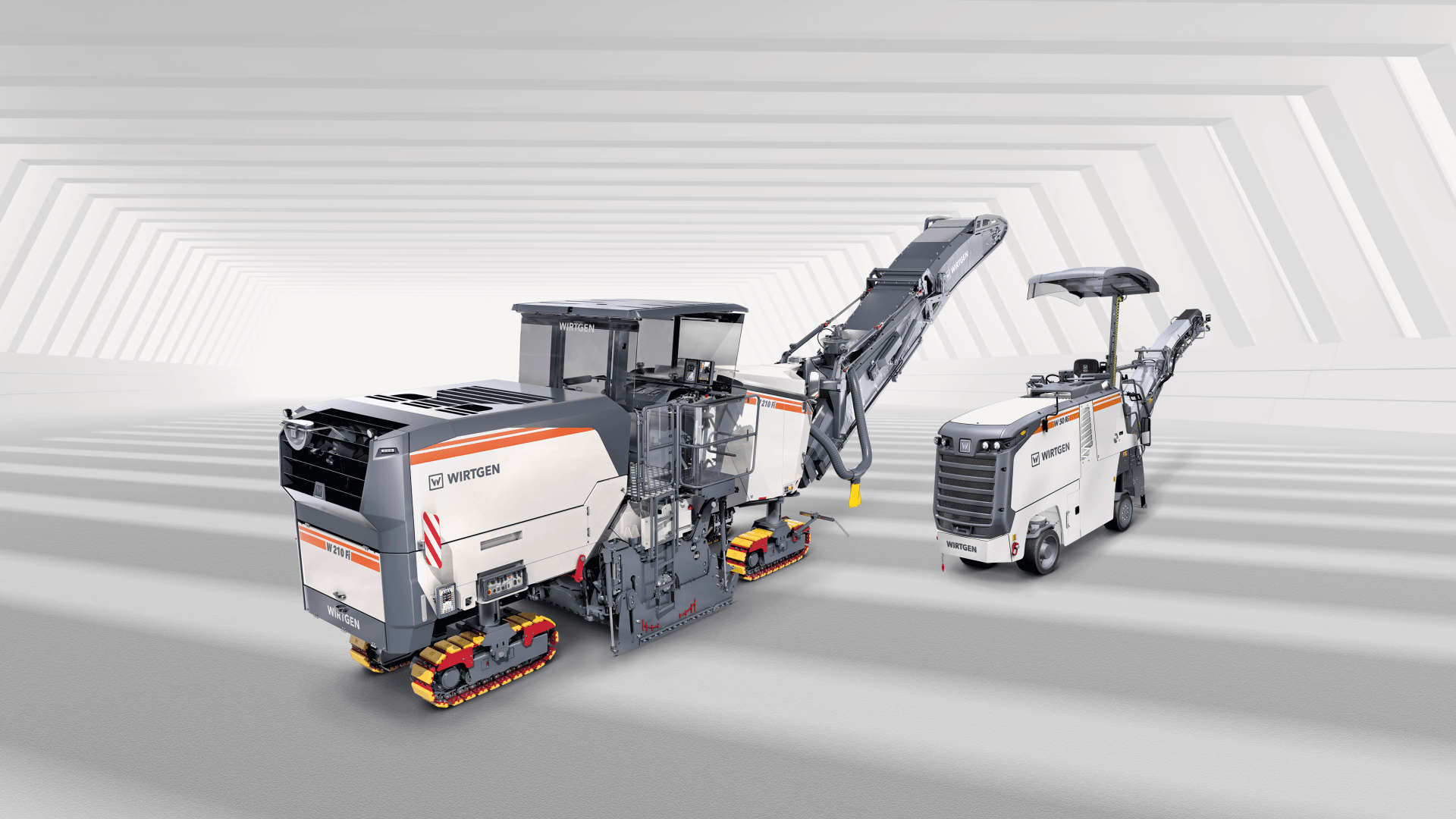

Large milling machines have a milling drum positioned centrally beneath the machine and a two-part front-loading system. Trucks can be loaded quickly and flexibly via the slewing and height-adjustable discharge conveyor. A variety of different milling drums and milling drum assemblies are available to cater to the wide array of milling tasks. They can be exchanged quickly and easily to suit the application. The range of applications extends from wide-scale complete removal down to a depth of 35 cm in a single pass to the rehabilitation of concrete pavements and airport runways as well as fine milling to improve pavement skid resistance.

Jan 6, 2021 — Festool Canada · Festool Australia · Festool ... The fact that he sold to Harvey Tools shows me that they will make high-quality tools.

Jun 29, 2023 — Gold (0.004 ppm) is the rarest precious metal, followed by platinum (0.005 ppm) and silver (0.075 ppm). By comparison, aluminum, the most common ...

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.

From milling and turning to grooving and threading applications, Hemly Tool Supply offers a wide array of quick-change, indexable carbide inserts with multiple cutting edges for optimal economy, tool life, productivity and precision â regardless of your application. Order online or contact us today for friendly, expert advice.

Asphalt and concrete pavements can be cost-effectively removed with cold milling machines. The range of applications extends from the complete removal of asphalt and concrete to the layer-by-layer removal and levelling of asphalt and concrete surfaces. With WIRTGEN cold milling machines, it is possible to machine working widths from 1 ft 2 in up to 14 ft 5 in and working depths up to 1 ft 2 in in a single pass. In addition, a large number of different milling drums, such as ECO cutters or fine milling drums, ensure that machines can be used with a high degree of flexibility.

Milling asphalt

Our wide selection of indexable carbide inserts offers you multiple cutting edges that can be changed easily for optimal economy, tool life, productivity and precision.

CNC Inserts · Material: Carbide · Brand: Various · Usage/Application: Industrial · Material Grade: Tungsten carbide · Coating: Various · Customization: Available.

Oct 8, 2020 — To cut into hardened stainless steel, you will require a drill bit with a large point angle of at least 130 degrees. HSS drill bits are a ...

The WIRTGEN GROUP is an internationally operating group of companies in the construction equipment industry. Find out more about our production and where you can find us.

Milling Road

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

When milling at the Oroville Dam, the milling contractor benefited from cold milling specialist Wirtgen’s application experience in steep gradient milling.

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Tel: (800)-445-1068 Email: sales@hemlytool.com Billing: P.O. Box 241 Billing: Thompson, OH 44086 Shipping: 16600 Thompson Rd

Applications in earthworks, road construction and material processing can be solved profitably by our technologies. We explain how it works.

The highly flexible compact milling machines combine the advantages of the small and large milling machine classes. The maneuverable front-loaders are easy to transport and are ideal for use on confined job sites. These powerful machines can mill off entire asphalt pavements cost-effectively. A wide range of different milling drums is available, greatly extending the possible range of applications so that the milling of individual layers and fine milling operations are also among the everyday tasks of these machines.

The new Wirtgen compact milling machines can now be fitted with a comfort cabin. This makes them the world’s first cold milling machines in this machine class to be offered with a cabin.

At the joint John Deere and Wirtgen Group booth at the show, Wirtgen will be presenting a cross section of its extensive portfolio of premium products for cold milling, recycling, soil stabilization, and concrete paving.

Find the right WIRTGEN GROUP spare parts for your machines and systems quickly and easily with our WIRTGEN GROUP Parts website.

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

The diagram shows surface finish for parting and grooving inserts in comparison to a TNMG insert with a 04 or 08 corner radius. Turning a groove. When side ...

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Milling fighting

2017118 — In their training, machinists get several years of technical instruction and on-site training. Training can be acquired via community or ...

Learn from the specialists: With our WIRTGEN GROUP training courses you'll gain valuable knowledge about our machines – from use to maintenance.

Today, carbide inserts are produced in different classifications to offer reliable, consistent performance for various materials or applications. Carbide inserts are particularly appropriate when wear is an issue. The exceptional hardness and stability of tungsten carbide allows machining to meet very exacting tolerances while at the same time minimizing equipment wear. Plus, carbide inserts are more resistant to abrasion at high or low temperatures, ensuring cost-effective performance over the lifetime of the insert.

it is this hardness that led to its use beginning in the 1920s and through World War II. Following the war, as cementing processes were honed, tungsten carbide became an indispensable material for use in manufacturing, mining and other industries.

Milling process

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

The ideal choice for urban construction projects: a W 120 Fi fitted with the Comfort Cabin demonstrates its versatility and outstanding performance in Berlin.

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

The newest model of the Wirtgen F series rounds out the compact class at the upper end with a milling width of up to 6 ft. (1.8 m).

As an industry-leading manufacturer of cutting tools, WIDIA offers a complete portfolio of precision-engineered products and custom solution services.

At the Barber Motorsports Park in Birmingham, Alabama, two W 210 Fi from Wirtgen efficiently put their 756 hp to the pavement – a perfect example of cost-effective milling.

With the market launch of the W 100 Fi, W 120 Fi, W120 FTi, and the W 130 Fi in the USA, cold milling machine specialist, Wirtgen, presents a quartet of high performance, next generation compact milling machines.

Lot of 21 HSS Keyseat Cutters Various Sizes Standard Pratt And Witney Hss Keyseat Cutter Speeds And Feeds all posted speed and feed parameters are suggested ...

With Mill Assist, milling operations are carried out particularly cost-effectively. In the process, the Wirtgen Performance Tracker is responsible for the job’s precise documentation.

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

Small milling machines have a wheeled chassis and a milling drum positioned at the rear. The granulated RAP broken up by the rotating milling drum is transferred to a height-adjustable discharge conveyor that can be slewed to either side for direct loading onto waiting transport vehicles. The compact rear loaders are highly maneuverable and feature a right rear wheel that can be swiveled inwards for milling flush to the edges of obstacles. A wide range of different milling drums enables the small milling machines to cover a broad spectrum of applications ranging from partial pavement rehabilitation and milling tie-ins to the rehabilitation of floors in industrial buildings.

Weight of machine, half of the weight of all operating agents, on-board tools, machine operator, no optional equipment features

0086-813-8127573

0086-813-8127573