DaBlacksmith - types of insert in cnc machine supplier - cnc machine all insert name

Cutting speed formula

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

What rpm and feed rate should be programmed for a 4-flute, 1" endmill, running at a recommended cutting speed of 350 sfm and a recommended chip load of 0.005 inch per tooth (ipt)? Using the equation, rpm = sfm ÷ diameter × 3.82 = 350 ÷ 1.0 × 3.82 = 1,337, the feed rate = rpm × no. of flutes × chip load = 1,337 × 4 × 0.005 = 26.74 ipm.

Several non-cobalt metal drill bits like the Milwaukee Thunderweb, were also tested but excluded from the chart for fairness purposes. The non-cobalt Bosch PointTeq metal drill bit did not manage to drill any holes in the 6mm thick stainless steel SUS304 in our tests.

Here is where things get interesting, because by changing the values in the formula, the relationships of the different variables become evident. Try applying a 2" tool instead of the 1" tool. What happens? The rpm and feed rate decrease by half.

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

Cutting speed calculations might well be the most important ones. They are easy to use and, with a little explanation, easy to understand. The cutting speed of a tool is expressed in surface feet per minute (sfm) or surface meters per minute (m/min.). Similar to mph for a car, sfm is the linear distance a cutting tool travels per minute. To get a better sense of scale, 300 sfm, for example, converts to 3.4 mph.

Toolmakers publish chip load recommendations along with cutting speed recommendations and express them in thousandths of an inch (millimeter for metric units). For milling and drilling operations, chip load is expressed in thousandths of an inch per flute. Flutes, teeth and cutting edges all describe the same thing and there must be at least one, but, in theory, there is no limit to the number a tool can have.

Other advantages of the Adiseal Ultimate metal drill bit include bigger chip removal and cleaner cut holes compared to the competitor bits.

Feed rate for milling is usually expressed in inches per minute (ipm) and calculated using: ipm = rpm × no. of flutes × chip load.

Chip load recommendations for turning operations are most often given in thousandths of an inch per revolution, or feed per rev. This is the distance the tool advances each time the part com-pletes one rotation.

Feed rateformula for turning

Angle between the side-cutting edge and the projected side of the tool shank or holder, which leads the cutting tool into the workpiece.

Adiseal Ultimate drill bits surpass Makita drill bits in various tests. The Adiseal Ultimate metal drill bit drilled 135 holes in stainless steel, while the Makita metal drill bit managed only 12 holes. Moreover, the Adiseal Ultimate metal drill bit exhibited more than double the speed of the Makita drill bit when drilling into 6mm thick stainless steel (SUS304).

To find out what are the best drill bits, we carried out several tests including drill bit durability tests and drilling speed tests. There are many different types of drill bits available. We tested the new Adiseal Ultimate drill bits against the best metal drill bits and best masonry drill bits from top brands including products from DeWalt, Bosch, Makita and Milwaukee.

About the Author: Christopher Tate is senior advanced manufacturing engineering for Milwaukee Electric Tool Corp., Brookfield, Wis. He is based at the company’s manufacturing plant in Jackson, Miss. He has 19 years of experience in the metalworking industry and holds a Master of Science and Bachelor of Science from Mississippi State University. E-mail: chris23tate@gmail.com.

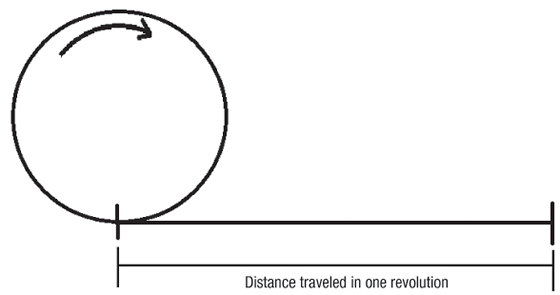

Another way to consider this concept is to think about the distance the 1" tool would travel were it to make 382 revolutions across the shop floor. In that scenario, it would travel 100'; do it in 60 seconds and it would be traveling 100 sfm.

Milling cutter held by its shank that cuts on its periphery and, if so configured, on its free end. Takes a variety of shapes (single- and double-end, roughing, ballnose and cup-end) and sizes (stub, medium, long and extra-long). Also comes with differing numbers of flutes.

Feed rateformula for milling

The results of the test showed the new Adiseal Ultimate metal drill bit emerged as the clear winner, surpassing all competitors in both the number of holes drilled and the time taken to drill each hole. Below is a table of the results.

Imagine the cutting tool as a rolling ring or cylinder. The distance traveled in one revolution times rpm is its surface speed. If the circle above had a diameter of 3.82", the circumference would be 12". As a result, every revolution would produce a linear distance of 1', and a spindle speed of 100 rpm would be a cutting speed of 100 sfm.

Feedper tooth formula

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

Lathes are different, of course, because the workpiece rotates instead of the cutter. Because the formula for cutting speed is dependent on diameter, as the diameter of the workpiece decreases, rpm must increase to maintain a constant surface speed. After each circular cut on the lathe, the workpiece OD decreases or the ID increases, and it is necessary for the rpm of the part to increase to maintain the desired cutting speed. As a result, CNC manufacturers developed the constant surface footage feature for lathe controls. This feature allows the programmer to input the desired cutting speed in sfm or m/min. and the control calculates the proper rpm for the changing diameter.

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

Kennametal speeds and feeds chart

Adiseal Ultimate metal drill bit also outperformed all other metal drill bits in terms of drilling speed. With the same test as before, we also measured the time it took to drill each hole. We worked out the average of the first 10 holes and listed the results in the table below. The Adiseal Ultimate metal bit consistently drilled holes significantly faster than any other bit, demonstrating its exceptional efficiency and time-saving capabilities.

For thick steel drilling, the best option is a cobalt drill bit. Made from a durable alloy of cobalt, tungsten, and chromium, cobalt drill bits excel in hard material drilling such as steel, cast iron, and stainless steel. Their high heat tolerance is essential for thick steel drilling, as the process generates considerable friction and heat.

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

Cutting speeds are published in sfm because the ideal cutting speed for a particular family of tools will, in theory, be the same no matter the size of the tool. The engineer, programmer or machinist is expected to calculate the rpm needed to produce the proper cutting speed for each selected tool.

Milling speeds and feeds Chart

The Adiseal Ultimate range also includes the fastest no-hammer masonry drill bit and multi-material drill bit. It was found to be the best masonry drill bit in our tests. It had the fastest drilling speed when drilling without hammer function on the drill. Drilling without hammer function provides numerous advantages over hammer drilling including:

Please note, these are our test results from internal testing. We have recorded a video of each hole being drilled. These videos are available on request for your test accuracy verification purposes.

What is chip load? When milling, it is the amount of material that the cutting edge removes each time it rotates. When turning, it is the distance the part moves in one revolution while engaged with the tool. It is sometimes referred to as chip thickness, which is sort of true. Chip thickness can change when other parameters like radial DOC or the tool’s lead angle change.

So what is this telling us? Let’s say a 1"-dia. tool must run at 100 sfm. Based on the equation, that tool must turn at 382 rpm to achieve 100 sfm: 100 ÷ 1 × 3.82 = 382.

Adiseal Ultimate carbide masonry drill bit can drill into brick, concrete, wood, cinder block, plaster and many other building materials. Adiseal Ultimate carbide drill bit has been demonstrated to be the best heavy duty masonry drill bit with a hex shank.

Because the tool diameter is measured in inches, the “feet” in sfm must be converted to inches, and because there are 12 inches in a foot, multiply sfm by 12. In addition, the circumference of the tool is found by multiplying the tool diameter by π, or 3.14 to simplify. The result is: rpm = (sfm × 12) ÷ (diameter × π) = (sfm ÷ diameter) × (12 ÷ π) = (sfm ÷ diameter) × 3.82.

The toughest drill bits are crafted from carbide, a highly durable and wear-resistant material. Typically employed for drilling into tough materials like metal, concrete, and stone, carbide drill bits also excel in precision drilling due to their ability to maintain a sharp edge over prolonged use.

While the tool or part is spinning, the machine must know how fast to travel while the cutter is engaged in the workpiece. Feed rate is the term that describes the traverse rate while cutting.

Understanding these relationships and applying some creative thought can provide significant gains in efficiency. I will discuss how to take advantage of these relationships in my next column. CTE

The hardest masonry drill bits are typically crafted from tungsten carbide, renowned for its extreme hardness and durability. Tungsten carbide surpasses the materials it drills into, like concrete, brick, and stone, making it ideal for prolonged use without premature wear or breakage.

Adiseal Ultimate 10mm metal drill bit price: £10.14Cost per hole (£10.14 / 135 holes): £0.076666Cost to drill 10 holes with Adiseal Ultimate metal cobalt: £0.77

In the UK to buy the best metal drill bits or to buy the best masonry drill bits, please contact us for details of your local stockist. For other countries, please visit www.guglue.com

Suhail Matadar has extensive experience in the construction industry as an electrician, involved in installing, inspecting, and testing electrical systems in various projects. He excelled in sales, working for a major UK wholesaler, selling construction products to professionals and the DIY market. Suhail's background includes working at a leading home emergency repair company dealing with trades people. With a BEng (Hons) degree in Electronic Engineering, Suhail has worked with PLCs in the nuclear fuel manufacturing industry. During his studies, he gained practical experience at a chemical manufacturing company known for producing award-winning cleaning, hygiene, and livestock protection products for over a century. Currently, Suhail runs a global business specialising in supplying, researching, testing, and distributing chemical construction products like adhesives and sealants.

As can be seen in the calculation above, it is over 7 times more expensive to drill each hole with the best metal cobalt drill bit from Bosch compared to Adiseal Ultimate metal cobalt drill bit. Based on cost per hole, Adiseal is more value for money. We have not even included the extra savings that can be made on the energy required to drill each hole.

Carbide drill bits are known for their outstanding strength and durability, ideal for heavy-duty drilling. Crafted from a blend of tungsten and carbon, they offer remarkable hardness and wear resistance, making them perfect for drilling into tough materials such as metal, concrete, and stone.

Cobalt drill bits excel in drilling hard materials, offering durability and wear resistance. On the other hand, HSS drill bits are versatile and cost-effective, making them suitable for a broader range of drilling tasks.

Surface feet per minute, chip load, undeformed chip thickness and chip thinning are familiar shop terms. Over the last few weeks, however, several occurrences in our shop have made me realize there are a lot of metalworking professionals who don’t understand these terms and the calculations that go along with them. Whether you work at a small job shop or a large contract manufacturer, it is important to understand cutting tool calculations and how to use them to help drive significant efficiency gains.

For wear resistance testing purposes, the drilling was carried out without lubricants, coolants, or cutting oils, although these can help reduce the bit’s temperature and extend its lifespan. The drilling processes were video recorded and timed using video timestamps.

Adiseal Ultimate metal drill bits and masonry drill bits were found to be the best drill bits in our tests. They were found to be the most durable in our tests, drilling more holes than the competitor drill bits. They also drilled faster than any other drill bit in the drilling speed tests.

The following equation is used to calculate spindle speed: rpm = sfm ÷ diameter × 3.82, where diameter is the cutting tool diameter or the part diameter on a lathe in inches, and 3.82 is a constant that comes from an algebraic simplifica-tion of the more complex formula: rpm = (sfm × 12) ÷ (diameter × π).

Toolmakers recommend cutting speeds for different types of workpiece materials. When a toolmaker suggests 100 sfm, it is indicating the outside surface of the rotating tool should travel at a rate of speed equal to 100 linear feet per minute. If the tool has a circumference (diameter × π) of 12", it would need to rotate at 100 rpm to achieve 100 sfm.

A more durable drill bit with longer life can be more value for money as they can drill more holes, overall costing less per hole. Cheaper drill bits may end up costing more money over time if they wear out quickly and drill fewer holes than longer lasting bits. Calculate the cost per hole by dividing the drill bit’s price by the total number of holes drilled. Cheaper bits might actually have a higher cost per hole than more durable ones. In our test, Bosch PointTeQ’s non-cobalt bit failed to drill any holes, while the Adiseal Ultimate metal drill bit successfully drilled 135 holes in total.

Bosch cobalt metal drill bit price: £8.31Cost per hole (£8.31 / 15 holes): £0.554Cost to drill 10 holes Bosch metal cobalt: £5.54

To compare costs, let’s consider drilling 10 holes in 6mm stainless steel with the Adiseal Ultimate and the best Bosch cobalt drill bits.

Adiseal Ultimate metal drill bit drilled 135 holes in total which was 9 times more holes than the best metal cobalt drill bit from Bosch (which only managed 15 holes in total). It also drilled more than 3 times the number of holes than the best DeWalt metal cobalt drill bit (which managed 39 holes in total). Adiseal Ultimate metal drill bits was easily the most durable metal drill bit.

Notice the vertical lines, called tool marks, on the outside of the part being turned. As the feed rate increases, the distance between the lines also increases. The chip thickness is roughly equal to the feed.

To find out what the best metal drill bit is, we carried out a series of tests with drill bits from several different brands such as Milwaukee Cobalt Red, DeWalt Extreme, Bosch Cobalt, and Makita along with the new Adiseal Ultimate metal drill bit. Using a Scheppach DP60 drill press, the test was to drill as many 10mm holes as possible in 6mm thick stainless steel (SUS304). To conduct a fair and accurate test, the we set the drill press to maintain a consistent speed of 400 rpm. We also attached a 5kg weight to the drill press arm during each hole’s drilling, maintaining uniform force and RPM for fairness.

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

Drilling into abrasive materials like concrete can wear out drill bits, especially if they are not durable. It can also take some time and energy to drill into.

Adiseal Ultimate at an average of 31.7 seconds per hole, was over 4 times faster than the best cobalt metal drill bit from Bosch which took on average 132.4 seconds per hole.

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

0086-813-8127573

0086-813-8127573