DATRON Dynamics, Inc. overview - Explorium - datron dynamics

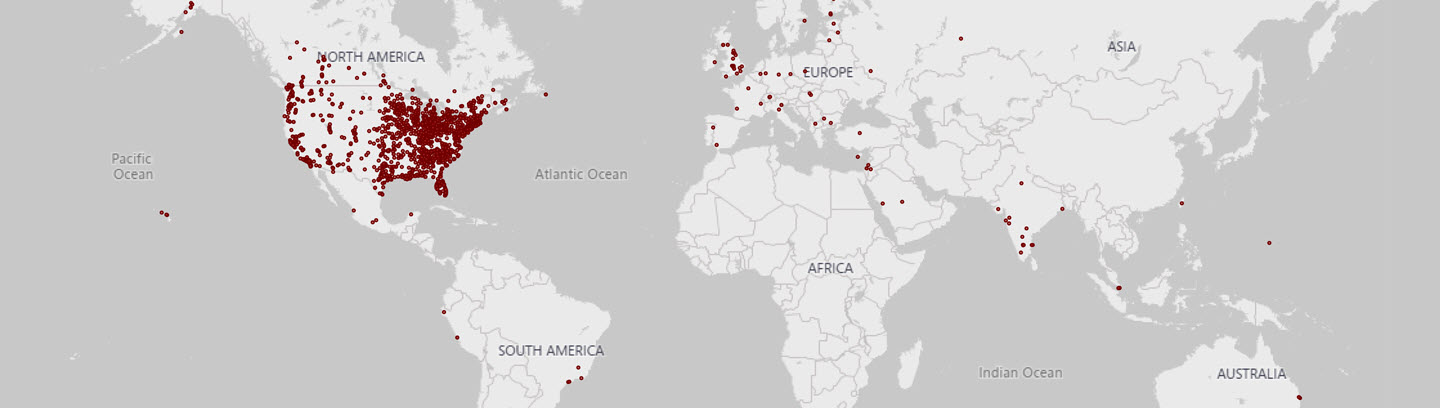

When you’ve worked in the special tools business for over 80 years –and won as many awards and certificates as we have – you’ve got to believe we’re doing something right. Our clients think so, too. RTS serves all of the major automotive, aerospace, appliance and aftermarket manufacturers in North America. Tier I, Tier II, and commodity managers are among our most valued customers.

I recently had your company do some reconditioning work on quite a few end mills and related items. So far, I am very pleased with the quality surface finishes I am getting on the wide variety of parts I manufacture. I will gladly have RTS do more reconditioning work for me as the need arises.

The cutters arrived yesterday and they look like jewelry. I just finished using them and they worked flawlessly. I have not pressure tested a manifold pump in the cavity just yet but I do not expect any issues.

My local supplier has razor sharp quality carbide for really cheap. But no 3-flute in this length, only in Standard length. (Upcut bits)

Had no issues. I’d probably try upping the DOC next time. This was on a piece 1.5" deep doing a contour with roughing passes, so lots of stickout. 1 roughing pass helped with the rubbing no doubt, bit was barely warm after running a 30 minute job.

I’d love the rigidity of the 4, but not sure if the machine (SOPRO) would keep up. I guess I can just order one to find out, but figured I’d ask around, maybe some of the experienced folks like @Vince.Fab have some thoughts.

We would like to thank you for your outstanding service. The tool arrived and we are waiting for our machining expert to check it. Thank you and best regards

RTS has proven to be a first choice supplier when it comes to the cavity reamers and drills, as well as the custom group drills. The custom ground drill that RTS did for us, the still work flawlessly.

I just wanted to give you a little feedback on the Tapered Reamer you guys fabricated for us. It worked perfectly. Although we don’t usually have a high demand for custom made tooling, we do occasionally require it. I will definitely be contacting you again in the future with any similar needs!

Our origins began in the automotive industry, but with a focus on continued diversification we have expanded to cover many industrial markets. Learn More

We tested the form tools and they ran great at your parameters. Didn't make a peep and the surface finish is as good as our other tools . . . FYI, these speeds/feeds are about 15X faster than our old tools!

For an XL length (1.25" cutting length) 1/4" endmill, to cut a deeper piece of hardwood, would you choose a 2 flute or 4 flute? I ran a job with 2 flute, it worked well, although it was quite shrieky.

With over 80 years of experience helping customers to solve their cutting tool problems you can be sure we will have a solution for you. Learn More

No, I’d stick with two. I don’t think the 4 flute would last as long (rubbing), but if it’s cheap, you might try it. You may get better finish, especially on wood that tends to be prone to tear out. I’d like to see a video of a 6k cutting feedrate, though.

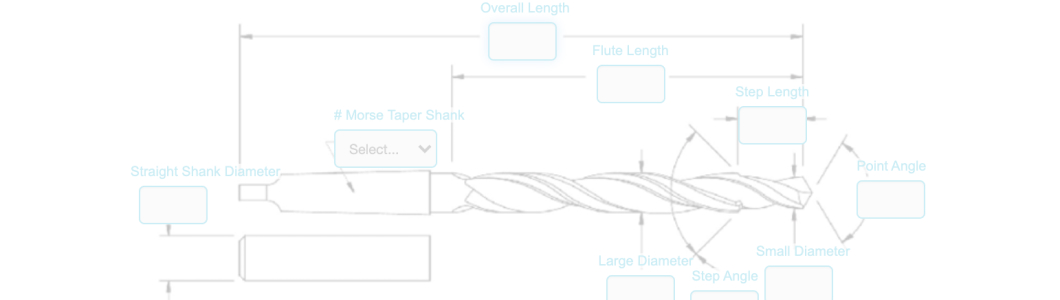

Our custom "blue print" cutting tools are manufactured from high speed steel or carbide that is the finest material available from select American suppliers. Learn More

I’m also thinking as it’s wood, the chipload isn’t as crucial as trying to cut metal - going to a 4 flute, keeping the feed to something with under a thou chipload, might still be fine?

Rodger, We received the tooling yesterday and we're impressed with the attention to detail as well as the quick turnaround. Thank you and your team.

0086-813-8127573

0086-813-8127573