Deburring - deburring hand tool

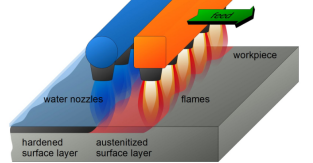

It is a surface hardening process normally used for complex-shaped steel parts. The steel is heated to high temperatures by using high-temperature flames like natural gas, propane, and oxyacetylene. This process is used for large and complex part heat treatments. Parts like gear and shafts are often hardened by this process.

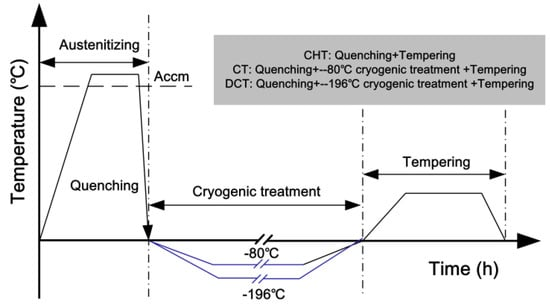

Is a post-heat treatment process that improves the ductility and toughness of the steel part. It reduces the internal stresses of the structure. The tempering involves heating at a temperature between 150°C to 600°C and then holding for certain hours before cooling. This process transforms martensite into tempered martensite.

First, clean the steel part surface thoroughly. Heat the part by using an oxy-acetylene torch to a high temperature of 800°C to 950°C. After heating rapidly cool the part by dipping it in water. For the thick steel part repeat the heating and quenching step several times. Tempering is optional to enhance the ductility of steel parts depending on application requirements.

A lot of real-world case studies on the failure of steel parts in service life refer to inappropriate heat treatment during the manufacturing of parts. All these studies conclude that the proper steel heat treatment steps and parameters should be followed during the manufacturing of parts to reduce failure during service life.

Tempering: In this process, quenched steel parts are heated below recrystallization temperature for several hours and then cooled to room temperature. This process removes internal stresses and improves the ductility of quenched steel parts.

The outer surface of the steel parts is hardened in this process. This process does not provide depth hardening. The case hardening processes are called carbonitriding, carburizing, and nitriding, Nitriding produces hard nitride using nitrogen, carburizing introduces carbon on steel parts surface while carbonitriding involves both nitrogen and carbon to increase hardness. The main advantage of case hardening is that it provides high hardness and wear resistance to steel surfaces keeping the core ductile. The main disadvantage is that it requires control process parameters.

Heating and cooling uniformity is affected by the steel thickness and shape. The risk of cracking and distortion is higher in complex-shaped and thick steel parts.

The steel hardening process causes changes in the microstructure of steel which changes the mechanical properties of steel. Heat treatment like quenching is done to convert steel microstructure to martensitic microstructure of steel which enhances the hardness of the steel. In this process, steel is heated to a high temperature and then rapidly cooled in water. This rapid cooling does not allow grains to grow properly like they can grow while cooling in room temperature. Quenching cool grains quickly after heating doesn't provide enough time for proper settling resulting in martensitic microstructure which is very hard and brittle. Similar to this other heat treatments are done to create pearlite or austenite microstructure which influence the hardness and toughness of steel parts. Some key factors that are crucial in effective steel hardening are heating and cooling rate, alloying elements, grain size, and the post-heat treatment processes. Proper following steel heat treatment tips and steps will lead to the production of effective steel parts with desired mechanical properties for particular applications.

Wrapping or distortion of steel components is seen particularly for complex shapes when they are rapidly cooled from high temperatures (quenching).

Not all but some hardening processes improve the machinability of steel which makes it easy to cut, shape, and finish steel parts.

The hardening process is done on steel to increase the strength and hardness of steel parts. Steel hardening techniques are performed on specific parameters to improve the mechanical properties, especially the hardness of the steel components. In this article, we will investigate 7 steel hardening techniques in detail which will provide expert guidance and practical insight. The reader will get to know the steel hardening process steps in detail and will know how each step contributes to the proper hardening of the steel parts.

High heat generation and generation of hazardous waste or chemicals involved in some heat treatment processes and post-treatment must be disposed of properly for reduced environmental impact.

Heat treatment helps us to tailor the properties of steel and steel alloys by adjusting hardening high temperatures, cooling temperatures, cooling mediums, and cooling rates making it desirable for a large range of applications.

High carbon content provides high hardness and brittleness while low carbon content provides ductility. Alloying elements like chromium nickel and molybdenum provide corrosion resistance, wear resistance, and strength to steel. Different composition has different microstructure and properties which is important in understanding what suitable heat treatments and parameters are required to enhance the properties of that specific steel alloy.

Steel hardening processes require specialized equipment like furnaces, post-hardening treatments, and skilled workers which increase the cost of the hardened steel parts.

The novel hardening process has been introduced by EU-funded researchers in which low-temperature surface hardening of stainless steel is done. This method ensures high hardness but also maintains high fatigue resistance and corrosion resistance. This steel hardening process steps include the implementation of plasma technology and a solution nitriding at lower temperatures.

Steel hardening is defined as a technique that is used to change the mechanical properties, especially enhancing the hardness and strength of the steel and steel alloys by changing the microstructure of the steel. Steel hardening may also include the addition of alloying elements. Steel hardening process steps are followed by different industries to manufacture a steel part with the desired properties. Numerous industries use different steel hardening techniques depending on their need. These industries include aerospace, automotive, and construction industry. Some steel grades that are subjected to hardening are listed below:

An additional Heat treatment process named cryogenic treatment is done after hardening and tempering. In this, the steel is subjected to extremely low temperatures of -185°Cor even lower for a long period. This process releases residual stresses from steel parts providing enhanced wear resistance, thermal fatigue, and corrosion. This process is used in the manufacturing of dies, cutting tools, and punches for their prolonged life and enhanced mechanical properties.

Annealing: In this process, steel parts are heated to recrystallization temperature and then furnace-cooled. This heat treatment reduces hardness and increases ductility and toughness.

Some heat treatments like case hardening only harden steel from outside so limit the depth hardening. These types of hardening processes are suitable for certain applications.

Steel parts gone through hardening treatment show high resistance to abrasion and wear which increases the life of the hardened steel.

This heat treatment process is also named as salt bath nitriding. In this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. The bath contains a specific salt composition of nitrate and cyanide salts. This process causes the diffusion of nitrogen to the steel surface as a result nitride layer is formed. This nitride layer enhances surface hardness, wear resistance, and corrosion resistance of steel parts.

Hardened steel increases the brittleness of the steel increasing possibility of cracking and failure under certain conditions.

0.3% carbon steel is generally subjected to quenching and tempering. Carburizing or nitriding is used to harden 1018 steel, 1045 and 4140 steel is quenched and tempered. 1018 Steel are used in manufacturing of pins, shafts, studs, and bolts. 1045 Steel are used in manufacturing of hydraulic shafts gears, shafts, and axles. 4140 Steel is used in axles, gears, bolts, crankshafts, and machine tool spindles. The desired mechanical properties requirement for specific application will ensure the specific parameters for heat treatment.

This article provides a comprehensive overview of steel hardening techniques. Steel hardening is essential to tailor the mechanical properties of steel for specific applications. It provides wear resistance, abrasion resistance, and strength to steel parts.

Solution hardening, quenching, case hardening, induction hardening, and molten salt bath hardening all these processes can be used to make metal stronger.

Improperly following of steel hardening process steps may lead to improper quenching and heat treatment. This will lead to the formation of cracks ultimately compromising the integrity of steel parts.

This hardening process includes high-temperature heating of steel to 800°Cto 950°Cand then rapidly cooling in water followed by tempering to reduce internal stresses. The main advantage of the process is that it provides uniform mechanical properties throughout the steel part compared to case hardening which only hardened the surface.

This hardening process helps in selective hardening of the steel component. High temperature of 800°Cto 950°Cis produced by electromagnetic induction. The specific area is heated to austenitizing temperature which helps in localized fast heating. Which is then quenched for martensitic transformation and hardening subsequently.

Quenching: In this process, steel parts are heated above recrystallization temperature and then rapidly cooled in fluid-producing martensitic microstructure. This hardening process increases hardness and brittleness while decreasing ductility and toughness.

The microstructure of steel play’s important role in the hardening process. All hardening processes cause changes in the microstructure of steel in return changing the mechanical properties of steel. Steel composition is mainly of iron with some carbon content and alloying elements. Different compositions show different microstructures which undergo a transformation when heat treated. When heated above a certain temperature the steel microstructure transforms from ferritic to austenitic which causes dissolution of carbon content and lattice homogenization. Martensitic microstructure in steel is formed when hot metal is rapidly cooled in water. This structure is highly brittle and hard due to high internal stresses and trapped carbon content. This quenched structure is then heated to a high temperature for tempering. Tempering reduces brittleness by secondary phases of precipitation enhancing toughness and ductility

Every application requires different mechanical properties which include toughness, hardness, and strength. In designing a specific component, it is essential to know that what are the required mechanical properties for that application.

0086-813-8127573

0086-813-8127573