DEWALT® Power Tools Official Site | Guaranteed Tough® - man about tools.com

Thanks to decades of expertise in advance materials R&D and manufacturing, Element Six have pioneered the development of a world-first synthetic diamond speaker dome for high-end acoustics, which received the UK Queen's Award for Enterprise in Innovation.

Cvd diamondprice

From the physical aspect, the density of tungsten carbide products is the ratio of their mass to their volume. The density can be tested with an analytical balance. The density of tungsten carbide can be affected by the mass and the volume of the tungsten carbide. That means everything that can affect the mass or the volume can also affect the density.

CVD DiamondRing

Element Six offers a range of CVD diamond grades with unique properties, along with extensive application engineering services to build a bespoke solution for you.

CVD diamondvs HPHT

Tungsten carbide, also known as cemented carbide, is one of the materials used in modern industry. Tungsten carbide productions always have properties of high hardness, wear resistance, and good transverse rupture strength. Many physical properties are affected by the amount of cobalt and carbon, grain size, and porosity.

CVD DiamondEarrings

CVD diamondvs naturaldiamond

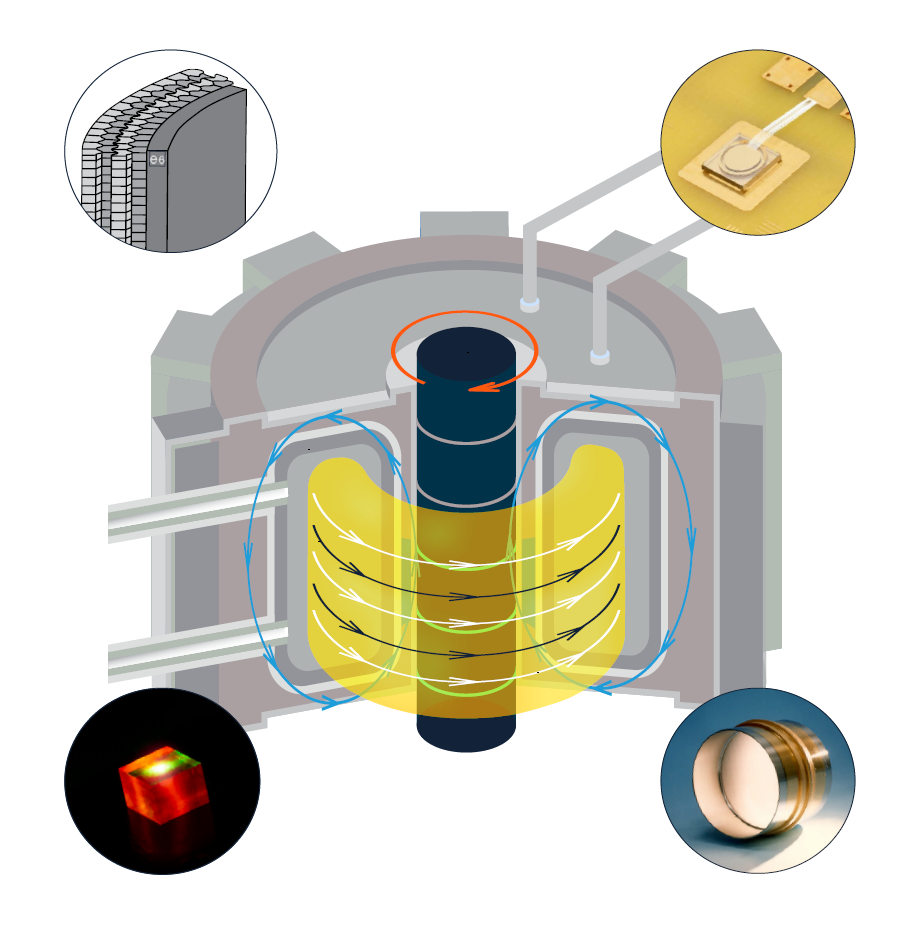

Capable of withstanding extreme conditions of heat and neutron irradiation, synthetic diamond and tungsten carbide are ideal engineering materials for fusion energy. To find out more, read our brochure or contact us today at E6marketing@e6.com.

As a bonder, less cobalt causes better hardness. And lower carbon can make tungsten carbide harder. But decarbonization can make tungsten carbide easier to damage. Generally, fine tungsten carbide will increase its hardness.

The amount of them can affect the density of tungsten carbide. The density of cobalt is larger than the density of carbon. So the more cobalt is in the tungsten carbide, the high density of tungsten carbide is. On the contrary, the more carbon is in the tungsten carbide, the lower density of the tungsten carbide. Porosity can also affect density. High porosity causes low density.

CVD diamondprocess

We’ll work with you to solve your challenges. Once we’ve found a solution, our global manufacturing capacity allows us to provide a consistent supply of materials that can scale up to meet your needs as they grow.

Free-standing CVD diamond doped with boron combines electrical conductivity with chemical inertness to make electrodes with unique properties and durability. Assembled into an electrochemical cell, Diamox, which won the 2017 Edison Best New Product Award for Environmental Quality, is used in electrochemical advanced oxidation processes.

Transverse rupture strength is the ability of tungsten carbide to resist bending. Tungsten carbide with better transverse rupture strength is more difficult to damage under impact. Fine tungsten carbide has better transverse rupture strength. And when the particles of tungsten carbide distribute evenly, the transverse is better, and the tungsten carbide is not easy to damage.

Element Six CVD diamond grades are engineered around your challenges, creating unique solutions in a range of applications. From unrivalled audio quality, electrochemistry to quantum optics, our world-class engineering expertise is paving the way for the next technological breakthroughs.

CVD diamondmachine

DNV-B1™ is our first widely-available, general-purpose quantum grade material, ideal for those interested in researching nitrogen-vacancy (NV) ensembles for quantum demonstrations, masers, detection of RF radiation, gyroscopes, sensing and further projects. | Order your samples today

Chemical vapour deposition (CVD) diamond can be tailored to help you overcome your engineering obstacles, tackle new fields of research, or performance that makes your brand and products stand out.

Quality check workers always inspect the metallographic structure under the metallurgical microscope. When excess cobalt concentrates on an area, it will form a cobalt pool.

From these physical properties, it is clear that tungsten carbide has many properties and advantages for mining, boring, cutting, and digging.

CVD diamondfull form

When you come up against a unique engineering or research challenge, sometimes conventional material solutions aren’t enough. You need something that can enable you to achieve the otherwise impossible.

We can know the amount of cobalt by testing the cobalt magnet with a cobalt magnetic tester. And the coercive field strength can also be tested with a coerciver.

To judge a material’s hardness is the same as its wear resistance. A tungsten carbide product with high hardness can endure impact and wear better, so it can work longer.

Electronic grade single crystal (ELSC™) is Element Six’s highest purity synthetic diamond grade. This makes it the perfect material for radiation hard, stable, highly selective ionizing radiation detectors, or as a host for spin defects for a number of quantum technologies. To find out more, read our dedicated datasheet or contact us today at e6marketing.com | Order your samples today

0086-813-8127573

0086-813-8127573