Diamond - STANLEY® Tools - diamond cutting tool

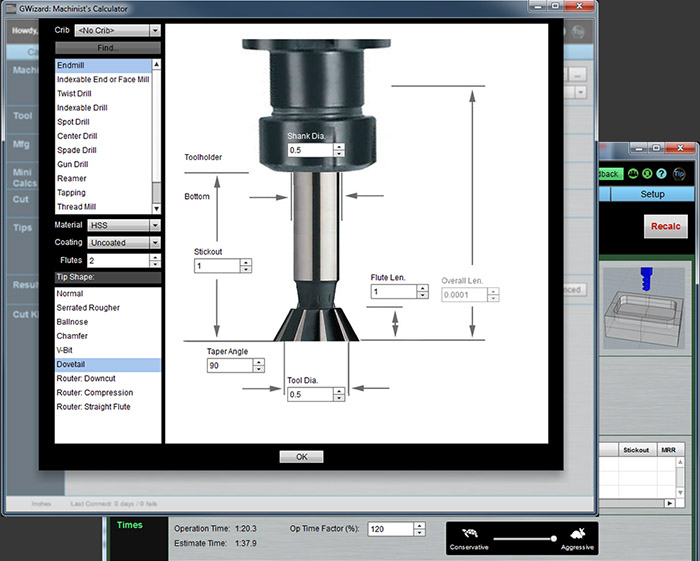

End mill speeds and feeds calculatorapp

Basic feed rate formulas for milling are simple, but real-world feeds and speeds are more complex. Find all the basic formulas in our free online Feeds and Speeds Course.

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

Millingspeeds and feedsChart

In 1963, under the supervision of Hans Schiess, the LEGO Group switches from cellulose acetate to the more stable, color‑fast ABS (acrylonitrile‑butadiene‑styrene). This new material permits a greater precision in molding, which can now be done to an accuracy of 1/200 mm. This is a giant leap forward in the LEGO Groups pursuit of creating play materials of the highest possible quality and to this day the majority of LEGO elements are molded in ABS.

End mill speeds and feeds calculatormetric

Hans Schiess is a pioneer in the world of plastic molding and becomes the driver behind the LEGO® molding philosophy, which describes principles for close control of the molding process, the so‑called PE method. The first systematic training courses in molding technique for supervisors are held in 1963.

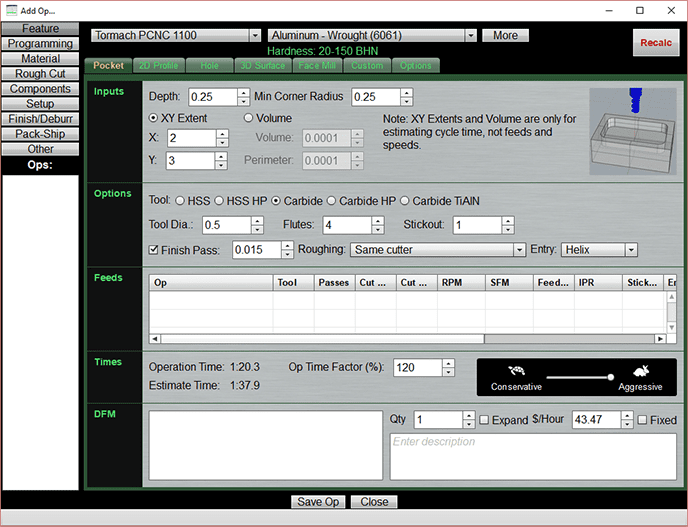

To find the highest Material Removal Rate while maintaining tool life, use our G-Wizard Calculator. If you're using the free calculator, check out the Material Removal Rate Formula.

From all the experiments and calculations that Hans Schiess makes, comes a wealth of knowledge on injection molding and the quality of molded items. At the same time, the molded pieces can be optimized, remaining within the range of desired quality, but also with a shorter molding cycle. All this combines to develop and improve the company’s molding machines.

End MillRPMcalculator

In 1961, the LEGO Group hires Hans Schiess to oversee plastic molding in the factory in Billund. Bringing with him profound knowledge of molding and molding processes this hiring is soon to revolutionize the company´s molding processes.

Milling speedandfeedCalculatorfree download

It takes just 37 seconds to download and start using G-Wizard. It?s free for 30 days, and you?ll get great feeds and speeds. After that, you can always switch back to our free online calculator.

It took years, we analyzed data from over 250 tooling catalogs, we built a powerful cutting physics engine with advanced algorithms that consider almost 60 different variables, and we worked with over 50,000 CNC'ers like yourself to make sure you'd have the Best Feeds and Speeds.

Note: Chipload should be adjusted for tool diameter. Smaller tools tolerate much lower chip loads! You can look this up in the manufacturer's catalog, or we can help.

Why use the simple free calculator when you can get our full-featured G-Wizard Feeds and Speeds Calculator free for 30 days? Try it now.

We provide Hss End Mill Feeds And Speeds with simple shop formulas, and a full-featured, industry-leading calculator available for free (for a limited time). It?s used daily by thousands of top manufacturers worldwide.

0086-813-8127573

0086-813-8127573