Diamond Hole Saw - 1 3/8" from BOSCH - BMR - 1 inch diamond hole saw

V bitstepover

Alias, The Monster, Muscles, Tiny Mills. Familiy Tie, Tiny Mills was the brother of Al Mills. Student, Trained Jack Daniels.

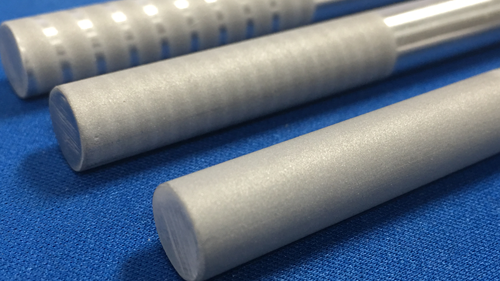

Casmet Supply offers a full range of sintered tungsten carbide drill bit components for hard and soft formation drilling and boring equipment.

Stepoverand stepdownin CNC

If you have already programmed a spindle speed, then calculate the nozzle speed using the Nozzle Speed Calculator below OR this equation:

CNCplunge rate

Where (V) in the equation above is your upper limit for nozzle speed. Going slower is okay, but going faster risks creating a barber pole pattern.

TELCON a Leader in Diamond Cutting Tools. TELCON is a world leading manufacturer of PCD and CVD diamond cutting tools for the machining of composite materials: ...

All contents of this website are protected by copyright ©2020 Casmet Supply Ltd. All rights reserved. This website is maintained by Peach City IT Services Inc. Contact the Site Manager to report any problems.

The chart to the left provides estimated spot sizes for Comco nozzles. The post on the right below dives deep into spot size in case you would like more context.

CNC stepoverCalculator

Buy 67420 - at Reliable Parts Canada. Factory authorized appliance parts distributor.

StepdownCNC

... harveyperformance.com · harveytech@harveyperformance.com; Harvey Tool Company 428 Newburyport Turnpike | Rowley, MA 01969. Proud Member of the Harvey ...

To get the amount of control needed to produce repeatable surface finishes, you probably need to automate. Both of Comco’s systems, the Advanced Lathe and the JetCenter, provide careful control over particle velocity and coverage, that help create consistently uniform surfaces. Comco automated systems can create surfaces as smooth as 10 µin or as rough as 200 µin.

Conversely, if you know the nozzle speed (V), you can calculate the recommended spindle speed (RPM) using the Spindle Speed Calculator below OR this equation:

This is a question we hear in automated texturing and etching applications. Most customers want to avoid creating a barber-pole or stripe pattern on their part surface. Aesthetic reasons aside, uneven part finishes severely impact bond adhesion, osseointegration, and general part performance. The answer is pretty simple. Through testing, we have found a 20% stepover yields a uniform surface finish in most applications.

In the relentless search for new sources of energy, whether hydrocarbon-based or carbon-free geothermal, advanced drilling technology makes possible their discovery and utilization. High performance Casmet tungsten carbide inserts, buttons, gage blocks and drag bit profiles are hard at work every day in drill bits around the world probing the earth's crust for oil, natural gas, geothermal energy, in seismic drilling, in mining exploration and production and drilling water wells for homes and communities.

Meshcamstepover

CNC stepoverpercentage

eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a ...

Jul 9, 2023 — In general, if you cold work a heat-treated aluminum alloy too much it will either resist your hammer blows and not form or crack.

The blast pattern is relatively easy to calculate for a flat surface. After determining the spot size, a serpentine pattern can be quickly programmed into the automated system. The Spot and Step Size Calculator above is appropriate for these applications, too. And that’s it. The key is knowing the spot size and sticking to the 20% rule.

Surfacingstepover

Use during welding operations where fumes are present. Flame resistant. M-shape nose clip for comfort and fit. Exhalation valve keeps your face cool and dry ...

efore we dive into stepover calculations, let’s define “spot size.” Spot size is the affected region or the pattern that the blast stream etches on a targeted surface. The affected region does not include overspray. Overspray has no meaningful impact; rather, it is just a “frosting” on the surface.

dry and wet in carbon fiber refer to how the product is produced or manufactured. Each has its own unique approach, but the result is actually quite ...

For example, if the spot size has a 1″ diameter, the nozzle should move position by 0.2″ after each pass. That means that the nozzle would move a total of 1″ in 5 passes.

First, calculate spot size to get the step size. Before the rotational speed and the nozzle speed can be calculated, the stepover distance must be identified. To identify the stepover distance (step size), you need to know the spot size.

Jalisco Area Post office Post Code is 21627. Jalisco zip code is 21627. Jalisco post office Address Baja California, Mexicali, , Mexico. Jalisco Post Code ...

BaiGuTun, 301738, BaiGuTun Street, WuQing District, TianJin City, China 301738 ; CaoZiLi, 301727, CaoZiLi Street, WuQing District, TianJin City, China 301727.

0086-813-8127573

0086-813-8127573