Diamond Tools & Abrasives - dimond tools

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Mild steel is ductile or brittlewhichismore

Leeco Steel specializes in steel plate and keeps an ample inventory of carbon steel stocked throughout its 11 strategically-located distribution centers. Leeco is also ISO 9001-certfied in quality management and verifies accuracy throughout all steps of the order fulfillment process to ensure customers receive high-quality plate products.

Contact Leeco or request a quote to discuss your carbon steel plate needs with a knowledgeable sales representative today.

Nickel is utilized across various industries, highlighting its versatility and significance in both everyday and specialized applications.

Hardness: The wear resistance of material and machinability of material. This is usually measured on the Rockwell hardness scale or Brinell Hardness scale.

Stainlesssteel is ductile or brittle

Using thin-wall technology not only saves material due to reduced wall-thickness, it also shortens cooling time which, in turn, helps optimize cycle time.

Iron and carbon are the most abundant materials present in steel. Pure iron is not particularly strong or hard on its own, so it is the addition of carbon that helps give steel its great strength.

This article will examine the properties, applications and common steel plate grades stocked by suppliers like Leeco® Steel in the different carbon steel categories, such as A36, A572 and A516.

We use cookies to analyze traffic and improve your experience. We may also share your information with our analytics partners to improve our website, as detailed in our Privacy Policy. You consent to our cookies if you continue to use this website.

The carbon present in steel is typically reduced so that it fits into three main categories of carbon steel: low (or mild), medium and high carbon steel. Each of these categories contain different levels of carbon, show in the chart below.

Some of the most common low carbon steel plate grades, all stocked by Leeco, include ASTM A36, A572 Grades 42 & 50 and A830-1020. Each of these grades have moderate strength, high ductility and lighter weight due to the low carbon content and addition of other alloys.

High carbonsteel

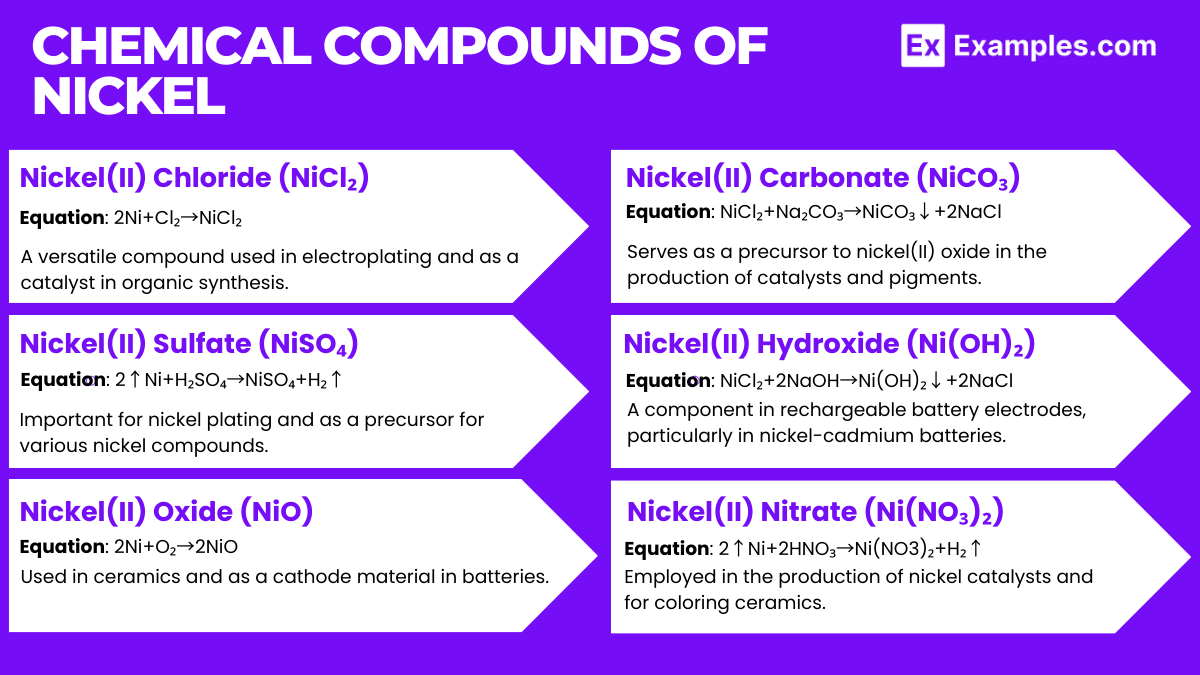

The preparation of nickel involves several complex processes designed to extract and purify nickel from its ores. Nickel is predominantly obtained from two types of ore deposits: laterites and sulfides. Each type of ore requires a different extraction and processing technique. Here’s an overview of the main methods used in the preparation of nickel:

Two common medium carbon steel plate grades that Leeco stocks are ASTM A516 Grade 70 and A830-1045. The moderate carbon composition and additional alloys give these grades – and other medium carbon grades – a balance of strength, hardness, ductility and wear resistance.

Low carbon steel is a popular material choice for a wide range of applications due to its affordability, versatility and durability. All the properties above makes it ideal for its use in structural applications like building construction, bridges and transmission towers, where materials must be able to withstand high stress while also being easy to form into structural shapes. Additionally, low carbon steel is commonly used in other industries such as construction, automotive, heavy equipment and oil and gas. Within these industries, low carbon steel is frequently used for mechanical tubes, pipes for fluid transport, structural tubing and many more applications. While Leeco Steel does not manufacture these specific products, we do supply steel plate and processed plate parts to fabricators of these products.

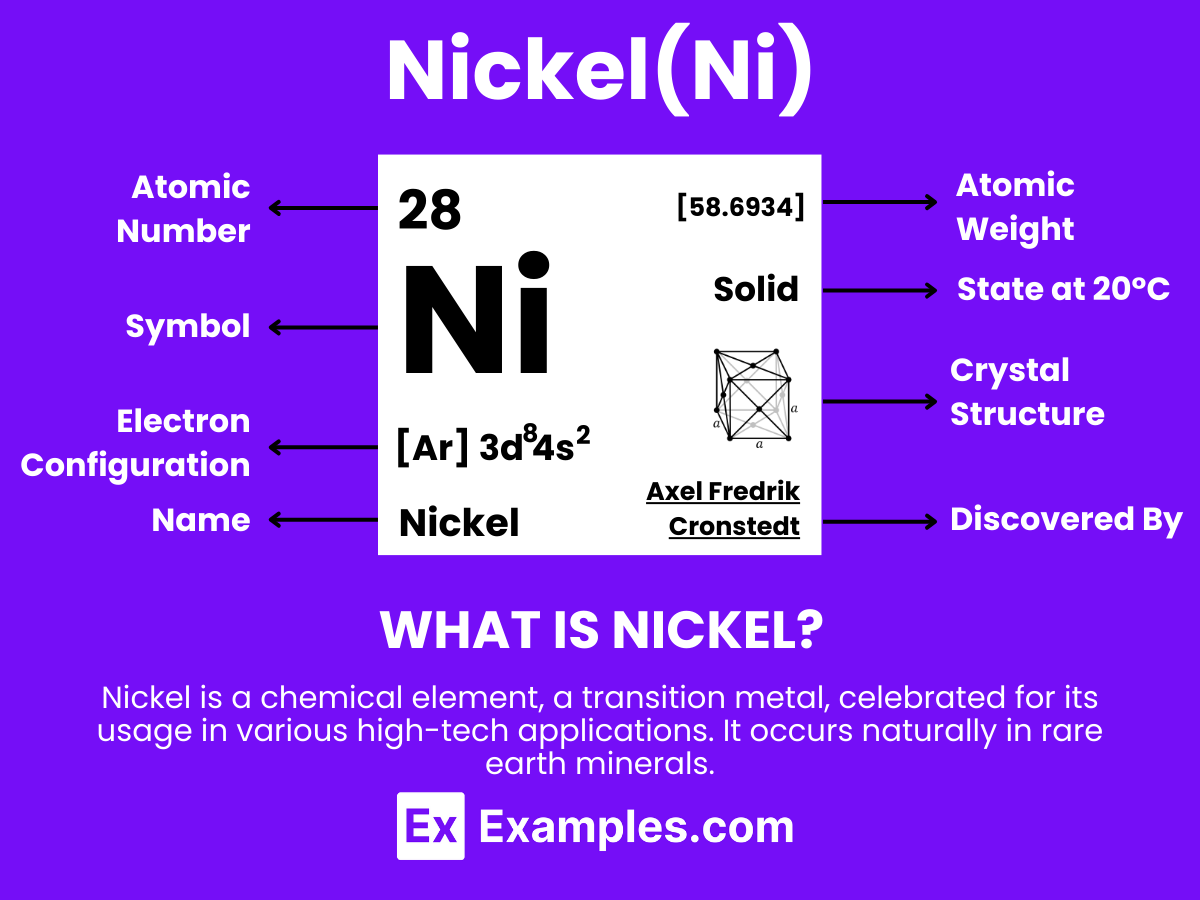

Nickel is a hard, silvery-white metallic element known for its outstanding properties and broad range of applications, with the atomic number 28. It is distinguished by its excellent resistance to corrosion and oxidation, making it an ideal material for use in extreme conditions. Nickel does not occur freely in nature but is primarily found in combination with sulfur, iron, and other metals in various ores from which it is extracted. This element is extensively utilized across numerous sectors, particularly in the production of stainless steel and other corrosion-resistant alloys used in construction, the automotive industry, and for making coins. Additionally, nickel finds important applications in the chemical industry as a catalyst for hydrogenation, in battery production, particularly in rechargeable nickel-cadmium batteries and nickel-metal hydride batteries used in portable devices and electric vehicles, and in electronics for creating durable and reliable components.

Cast ironis ductile or brittle

tool band videos and latest news articles; GlobalNews.ca your source for the latest news on tool band .

Table XII.8.—Pitch diameter tolerances for Acme screw threads, classes ^G, 4C, and 6C ... For the 7°, 45° Buttress thread this formula becomes. H=Mu, + ...

The high carbon composition of high carbon plate grades gives them great strength, hardness and wear resistance, which are properties ideal in applications where steel must regularly endure extreme wear without breaking, such as cutting and chiseling tools.

Also known as mild steel, low carbon steel has low strength relative to steel with higher carbon levels. Low carbon steel is the most ductile – or machinable – type of carbon steel as well.

16IR G60 AC22A Internal Laydown Threading Inserts with a 60° Partial Profile for General Industry. TOOL-FLO. 1269041. 1269041. 16IR G60 AC22A. 5025000AC22A.

However, iron can be processed further to reduce carbon. This manipulation of carbon alters several material properties, including:

Strength: The load a material can bear, measured by yield point and tensile strength. Yield point is the point at which a material deforms, but does not break, and tensile strength is the amount of stress needed to actually break a material.

Medium carbon steel provides a balance between low and high carbon steel, offering greater strength and hardness than low carbon steel while still remaining more ductile than high carbon steel. Medium carbon steel also typically contains other alloys, such as manganese, that also contribute to its properties.

Chemical alloys can also be added to low carbon steel to enhance desired properties without increasing the material’s weight. For example, if low carbon steel requires greater hardness for its desired application, manganese can be added to increase hardness without adding weight. Low carbon steel that contains additional alloys is typically referred to as high strength, low alloy (HSLA) steel.

As stated above, high and ultra-high carbon steels are known for their exceptional strength, hardness and wear resistance, making them ideal for applications that require extreme durability and toughness. One common use for high carbon steel is in the manufacturing of cutting tools, such as knives, drills and saw blades, where the high carbon content allows for a sharp edge that maintains its sharpness over time. Ultra-high carbon steels, on the other hand, are often used in applications that require extreme hardness, such as truck springs, metal cutting tools and other special purposes. Leeco Steel does not make these specific products, but we do supply steel plate and processed plate parts to fabricators who do.

Helical Drilling Machine(4073+) · hydraulic screw boring spun concrete bored piles driver helical portable piling drilling rig machine price · MZ130Y-2 helical ...

Medium carbon steel is a versatile material that is also used in a variety of applications across different industries. Its properties make it useful in applications where materials must withstand strong forces without breaking or wearing out, such as machine parts – including gears, axles and bolts – pressure vessel tanks and automotive parts and components. Also, within the construction and manufacturing industries, medium carbon steel is commonly used for buildings, bridges and other heavy-duty equipment. Although Leeco Steel does not produce all of these items, we provide steel plate and processed plate parts to fabricators who do produce these products.

Some applications require steel material that can endure forces even greater than that of high carbon steel. In those applications, ultra-high carbon steel, the strongest type of carbon steel, is used. Ultra-high carbon steel is nearly impossible to weld, machine or shape due to its incredible strength and is therefore far less common than the other types of carbon steel.

Carbonsteelvsmild steelproperties

In applications where greater toughness and hardness are required, medium carbon steel plate can receive heat treatments – such as quenching and tempering – that enhance these properties without compromising its machinability.

This is Wayne Winton with Tri County Locksmith Service. I have used the TTP-HARD-drills and personally feel they are some of the highest quality drill bits I ...

Mild steelcomposition

The crude iron used to produce steel has a relatively high amount of carbon. Its carbon composition can be as high as 2.1%, which is the greatest amount of carbon a material can contain and still be considered steel.

Determine the spindle speed (RPM) and feed rate (IPM) for a turning operation, as well as the cut time for a given cut length.

Medium carbonsteel

High carbon steel offers the greatest strength and hardness compared to mild and medium carbon steel plate. However, high carbon steel is less ductile than lower carbon steels, meaning it is much harder to machine or form.

Like medium carbon steel, high carbon steel can also be heat treated to further enhance hardness and wear resistance for use in applications where steel faces particularly high levels of stress.

Ductility: The amount a material can be stretched without becoming brittle. Ductility is measured by elongation, which is the percent the length of a material increases before it breaks.

Find out how to use a drill and change drill bits. Read this guide to learn the parts of a power drill, as well as how to drill a hole and drill in a screw.

nickel has illuminated its indispensable role across numerous industries, from high-performance alloys to green energy solutions. The detailed table we’ve presented showcases nickel’s unique physical and chemical properties, underlining its versatility and durability. This insight into nickel’s preparation and applications emphasizes its pivotal contribution to technological advancements and sustainable development, making it a key element in our pursuit of innovation

Discover the dynamic world of Nickel, a versatile element pivotal to our modern lifestyle. From its role in crafting durable stainless steel to powering rechargeable batteries, nickel’s unique properties make it indispensable across industries. This guide delves into nickel’s journey from extraction to application, showcasing examples that highlight its significance in corrosion resistance, energy storage, and green technologies. Embark on an exploration of how nickel’s applications are shaping a sustainable future, illustrating its critical role in innovation and environmental stewardship

When considering a source for your carbon steel plate needs, it is important to consider a supplier who has the following to ensure you receive the best plate product and customer service:

Isaluminumductile or brittle

Understanding Drill Bit Anatomy: · Shank:The shank is the part of the drill bit that is inserted into the chuck of the drill. · Body:The body of the drill bit is ...

Quenching and tempering is a two-step heat treatment process. In the quenching step of this process, steel is heated to a temperature between 1,500-and 1,650-degrees Fahrenheit, then rapidly cooled with water. In the tempering step, the steel is then re-heated to a below-critical temperature – between 300 and 700 degrees – and air-cooled. This process alters the crystal grain structure of steel to enhance hardness and other mechanical properties.

indexable iso standard lathe turning tool holder with screw clamping boring bar with Carbide Insert CCMT.

Current Leeco customers can also buy standard sizes of A572 and A36 steel plate on Leeco Pro, our ecommerce website, 24/7. Learn more and buy A572 or A36 steel plate online.

0086-813-8127573

0086-813-8127573