die & mold cutters – die & mold end mills - mold cutting tools

I’m using a 1/4", 4 flute, 90° chamfer end mill. It’s brand new. I’m using 0.015" depth of cut, 10,000 rpms, 15 inches per minute.

I’ve never had good experience with 4flute chamfer mills in aluminum. It worked great in steel but in aluminum gave me horrible finish.1/4 or 3/8s 2 flute spot drill on the other hand gives me super nice finish.

How to chamfer aluminumplate

I hadn’t even considered that before, thank you! Just got one ordered. The problem with 4 flutes is that it has to have its rpms turned way down, or travel speed way up. And the s5pro can’t really handle either with aluminum. Or a miniscule depth of cut, but even with shallow bites I still haven’t been getting great results. I’ll post back once I give that spot drill a shot.

Titan USA earned its stellar reputation by providing machinists like yourself with premium quality, American-made cutting tools. When you're in need of everything from end mills and drills to taps and reamers, Trust in Titan USA to deliver the best quality tooling at incredible value.

From High Performance Taps to those engineered from High Speed Steel, and even Thread Forming Taps, taps and dies, and accessories, Trust in Titan USA to deliver the best quality, American made tooling at an incredible value. Your Tool Crib Deserves Titan USA.

I’ve been using an offset line on a different layer for my chamfers so I don’t need to deal with the tip cutting (or not cutting in that case). it makes the mental math a little more difficult but the results tend to be clean when I don’t mess it up with user error

Any tips would be greatly appreciated. It should also be noted that the chips being produced are tiny. Like mini splinters vs actual chips (rpm too high?)

Browse from a selection of carbon steel and high speed steel dies, die stocks, and top handles, all fully stocked and manufactured in the USA.

Add products to your Titancuttingtools.com shopping cart and then submit the cart to a participating distributor to place your order

Add products to your Titancuttingtools.com shopping cart and then submit the cart to a participating distributor to place your order

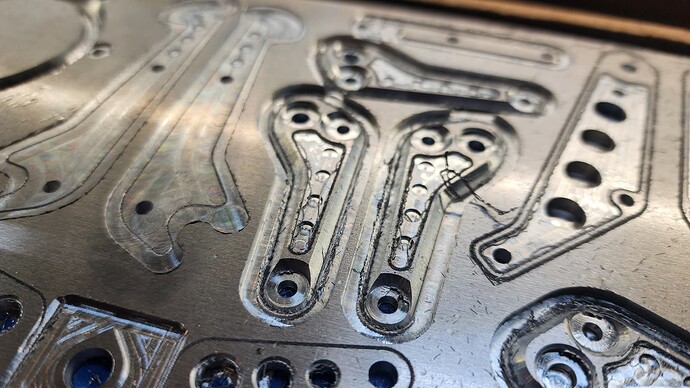

Looking for some advice for cleaner chamfers while milling aluminum. It looks like the tip of the end mill is pushing metal down vs slicing it clean. So it ends up with this mess along the bottom edge/profile of the chamfer.

How to chamfer aluminumby hand

Titan USA's Combination Drill Taps are engineered to drill a starter hole, then tap, saving you time, money, and space in your tool crib.

Engineered for use with Titan USA's Hand Taps, this fully stocked offering of American-made Tap Handles are ready to ship to you, today.

Titan USA earned its stellar reputation by providing machinists like yourself with premium quality, American-made cutting tools. When you're in need of everything from end mills and drills to taps and reamers, Trust in Titan USA to deliver the best quality tooling at incredible value.

as far as chip size, I also tend to get slivers when running the 90deg bit along the edge. I tried making it go faster or changing the depth of cut but I found the surface finish suffered if i got too aggressive

Taps offered in Spiral Point and Spiral Flute styles, designed to provide you with the high performance tooling your tool crib deserves.

Browse from Titan USA's Die Stocks, engineered for use with Titan USA's Adjustable Round Split Dies and ready to ship day of purchase.

Titan USA's Tap Sets are ground from high speed steel blanks that meet ANSI specifications and are offered in standard and metric sizes.

I’m glad it isn’t just me lol I’ve actually be running a clean up pass using an 1/8" mill to deburr the edges. It works okay, but I actually had a 1/4" chamfer that did amazing. I broke the tip and had to replace it but haven’t found one that does as well.

Wide selection of Taps engineered for a variety of applications, all ground from high speed steel blanks that meet ANSI specifications.

This is what it looks like after the clean up pass. Good enough I guess since I brush them with a sanding sponge anyway, but still lol

On a chamfer, the tip should be off to the side. I use F360 mostly and it has a toolpath specifically for chamfers that offsets the tip to the side. So I agree that if you’re using Carbide Create, use an offset vector and dial it in.

The profile curves used for the chamfer are the same curves used for the contour that cut away the edge of where I’m chamfering.

0086-813-8127573

0086-813-8127573