Different types of chips in metal cutting (Pdf) - EngineeringTribe - continuous chip with built up edge

ISO, a globally recognized body, sets standards that apply to industries worldwide. ISO carbide insert standards, represented by codes like "ISO 1832," define parameters for inserts used in turning, milling, and other metal-cutting processes. The ISO standard is widely accepted in Europe, Asia, and other parts of the world, making it the standard of choice for manufacturers with international operations or exports.

Precision Requirements: For applications demanding high precision, ISO inserts might be preferable due to their tighter tolerances.

Performance online catalogpdf

ANSI Standards: Tolerance levels may vary to match North American industry standards, which sometimes focus more on practical tolerance than on fine precision.

The ISO standard is often more versatile for global operations, while ANSI standards align with North American engineering norms, offering an advantage for U.S.-based manufacturers.

Performance online catalogfree shipping

In ISO standards, carbide inserts are typically designated with a specific code format that defines shape, clearance angle, tolerance, insert size, and more. For example, an ISO insert code might look like "CNMG 120408," where each letter and number refers to a particular characteristic, making it straightforward to understand the properties and application of the insert.

An ANSI insert code might look like "CNGP 432," following the standard U.S. practice of using inches instead of metric units in the coding system. While the coding principles remain similar, the differences in units and naming conventions can lead to confusion if not understood properly.

Adobe® Acrobat® Reader is freely distributable software that lets you view and print Adobe Portable Document Format (PDF) files on all major computer platforms, Click the graphic below to get your free up to date copy of Adobe Reader.

Performance online catalogfree

The ISO format provides a more granular understanding of the insertâs properties, which can be advantageous for applications requiring a high level of customization and precision.

ISO Standards: Better suited for industries and manufacturers with a global reach, providing a universal system compatible with international machines.

!! ALL PRICES LISTED ON THE WEBSITE AND IN THE CATALOG ARE SUBJECT TO CHANGE WITHOUT NOTICE !! !! CONFIRM PRICES WHEN PLACING AN ORDER !! Distributed as an Adobe PDF file. To view the PDF in your browser window, simple click on the link. Alternatively, to download the PDF, right-click on the link and choose "Save Target As..." and choose a location on your computer to save the PDF file. For Mozilla Firefox users, you must first open the PDF in your browser and then click the floppy disk icon that says "Click to save this file to your computer or another location".

Industry Standards: Certain industries may favor one standard over the other due to regional norms or regulatory requirements.

ANSI Standards: The ANSI coding system is shorter and more straightforward, focusing on essential insert characteristics without the additional layers of detail.

Chevyperformance online catalog

Performance online catalogcanada

Machine Compatibility: If your equipment is metric-based, ISO inserts might be more compatible, whereas imperial-based machines may benefit from ANSI inserts.

Operational Scale: For businesses operating globally, ISO standards offer greater consistency and compatibility. For U.S.-based operations, ANSI may align better with equipment and measurement preferences.

ANSI, on the other hand, is predominantly used in North America. The ANSI carbide insert standards align with the needs of American industries, offering similar classification codes but with distinct terminology and standards that match U.S. measurement preferences. While ANSI codes also designate insert shape, size, and other properties, they tend to differ slightly in format and measurement units.

ClassicPerformanceProductscatalog

:: Home :: Online Catalog :: Our Products :: Services :: Reference :: Contact Us :: TA Wagon :: Induction :: Ignition :: Cylinder Heads :: Valve Train :: Rotating Assembly :: Cooling System :: Oiling System :: Timing System :: Exhaust :: Gaskets & Seals :: Hardware :: Transmission :: Rear End Girdles :: Suspension :: Miscellaneous TA Performance Products 16167 N. 81st Street Scottsdale, AZ 85260 (480) 922-6807

POLPerformance Onlinecar parts

Despite their similarities, ISO and ANSI carbide insert standards have notable differences that can impact usability, compatibility, and selection.

The measurement system affects how insert sizes and tolerances are presented. A machinist working with American machinery may prefer ANSI inserts for ease of measurement, whereas ISO inserts are preferred for metric-based equipment.

Bestperformance online catalog

ISO Standards: Generally more elaborate and specific in coding, allowing more detailed designation of insert features such as insert type, relief angle, and cutting edge.

Understanding the differences between ISO and ANSI carbide insert standards is crucial for maximizing machining efficiency and achieving desired outcomes in various applications. While both standards serve similar purposes, their measurement systems, coding conventions, tolerance levels, and compatibility factors distinguish them in significant ways. For businesses and machinists, choosing the right standard can lead to improved performance, enhanced compatibility, and optimized costs. Whether youâre working in North America or internationally, aligning your insert selection with the appropriate standard is key to successful and efficient machining.

These differences in tolerance can affect performance in applications where accuracy is crucial, such as aerospace and automotive industries, where tighter tolerances reduce error margins.

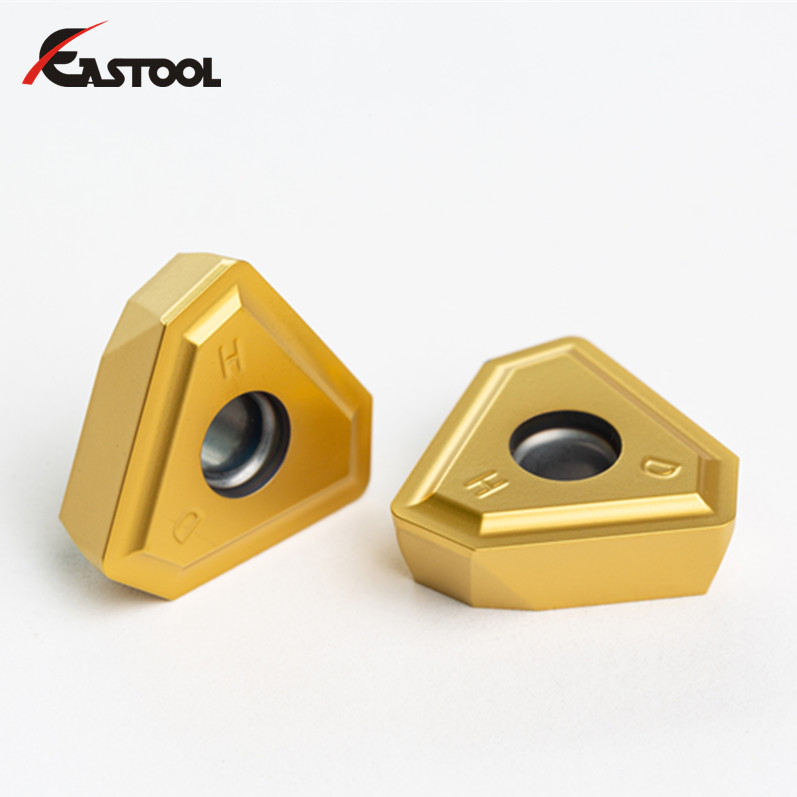

Carbide inserts come in various shapes, sizes, and geometries to meet the diverse demands of turning, milling, and other machining processes. Standards like ISO and ANSI provide guidelines for manufacturers and users to ensure compatibility and reliability across industries and regions. These standards cover aspects such as insert shape, size, tolerance, and designation codes, helping machinists identify the correct insert type for specific applications.

By adhering to these standards, manufacturers can ensure product quality and consistency, making it easier for users to choose the right inserts based on machine and application requirements.

Carbide inserts are vital tools in modern machining, providing the precision and durability required in cutting operations across various industries. However, understanding the differences between ISO (International Organization for Standardization) and ANSI (American National Standards Institute) standards can be crucial for manufacturers, machinists, and engineers seeking optimal performance in specific applications. This article explores these standards and highlights their unique attributes, helping users select the appropriate carbide inserts for their needs.

0086-813-8127573

0086-813-8127573