Do you tap or thread-mill? - power threading on mill

Our online store is your easy one-stop source for all things metalworking, and we’re positive we can help you find the perfect quality solutions for all your machine shop needs.

Can you hand tap with a form tap

Serving machine shops and job shops alike, Travers is your metalworking and industrial supply superstore with over 500,000 tools from more than 800 trusted brands, including a large Made-in-USA product offering.

May 25, 2023 — TiCN (titanium carbonitride): Bits made of titanium carbonitride are great for stainless steel, cast iron and aluminum. They are harder and more ...

Roll form tap chart

With my 1mm walls in mind, what would happen if I changed this setting in Slic3r to .5mm instead of .45? Is that ill advised because .45 is optimal for the .4mm nozzle diameter?

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

I would suggest turning off "ensure vertical shell thickness" in Print settings (always, not just for this). That is the worst feature in slic3r and has ruined more prints than I care to count. I should start a petition.

FormingTap set

2024517 — The key to high-feed milling is understanding the relationship between the radial engagement (ae) of the tool and the impact it has on the average chip ...

Formingtap vs cutting tap

Tactical Bricks · Videos · Shorts · Fully functional LEGO HI433 Instructions for sale right now on tacticalbricksusa.com!!! · Fully working lego HK433 available on ...

I'm currently making all my vertical walls 1mm thick, and I'm really impressed how well the MK3 handles these. They do come out relatively straight, smooth and rigid. Just curious if there is a theoretical sweet spot that I should be using instead. Multiples of .4 for example? .4 => .8 => 1.2 ?

Top Categories: Abrasive Products, Blow Guns, Hose, Tube, Fittings & Valves, Clamping, Workholding & Positioning, Cutting Tools, Hand Tools, Lubricants, ...

Please excuse my ignorance on this, as I'm relatively new to 3D printing. I am printing architectural/structural models, many of which have long, thin vertical walls. I'm wondering if the MK3 and its .4mm nozzle have an optimal wall thickness that should, at least in theory, yield higher quality output, reduced print time, reduced thrashing of the X axis, etc.

Threadforming taps

A good thin wall thickness is a multiple of extrusion width defined in the slicer (Slic3rPE is 0.45mm). 0.45mm, 0.90mm ... I use this when making models optimized for a specific printing.

You can change the widths in the Advanced Print settings in Slic3r PE. I have done some small tests, and found that .7mm single walls come out very nice. Just did a test print on a small wall that was .7mm thick, with all the widths set to .7mm in Slic3r. came out beautiful, albeit they measured 1.1mm with calipers.

How does a form tap work

Forming tapssizes

A common cutting tool material used to make both indexable inserts and solid cutting tools. Carbide tools are very hard and wear resistant. ... An alloy of iron, ...

For assistance with finding the right tools or any other questions, please feel free to call our customer support team at 800-221-0270 or use our chat feature now.

Ah, thanks. So with .45mm set as the extrusion width, does that mean a wall thickness of 1mm (rather than .9mm) is causing unnecessary extruder movements perpendicular to the length of the wall? Movements that could either reduce linear print consistency, or slow down the print?

The hardness of tungsten steel is second only to diamond, but it cannot be used as a blade for ordinary use. Speaking of tungsten steel, ...

Formingtap drill size

Crafted from high-quality carbon steel with a white zinc plating, these hardened flat head tiling concrete steel nails are designed for longevity and ...

Check out Mac Tools flyers for our best deals and view the Mac Tools catalog for our entire selection of hand tools, toolboxes, and more ... mail to 701 E. Joppa ...

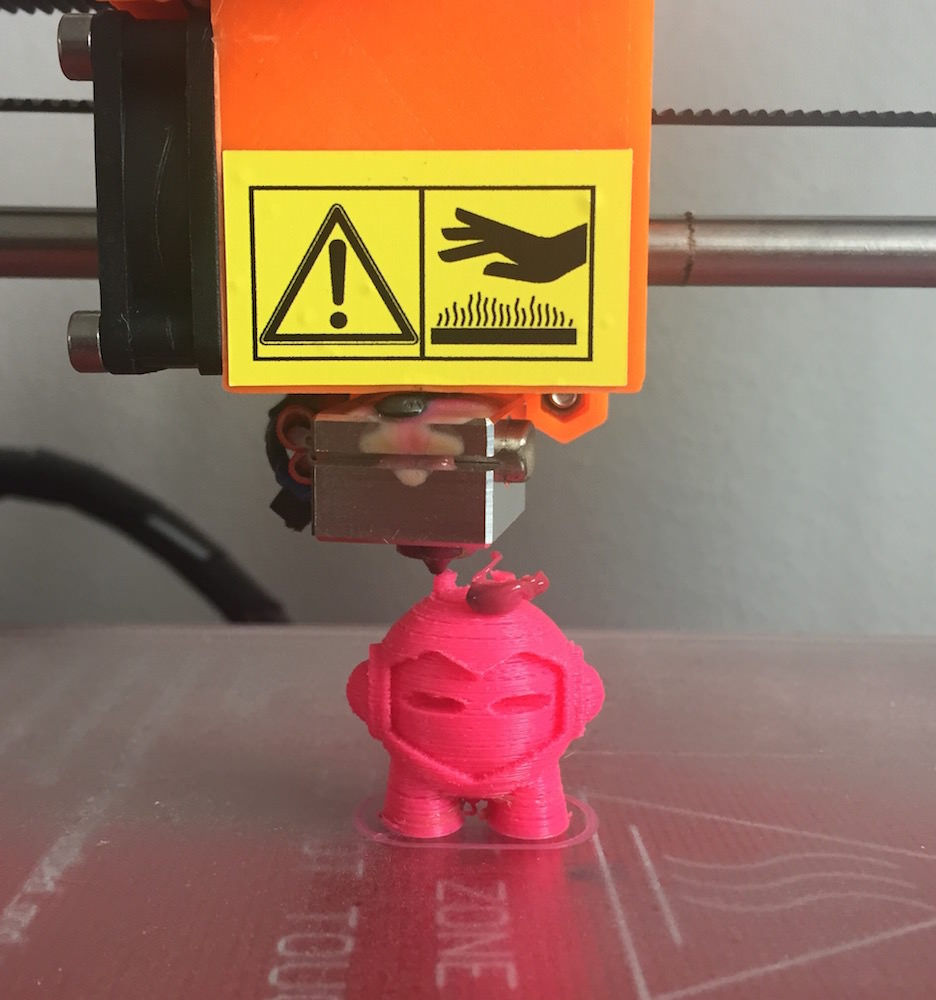

Yes, but feel free to set the parameter width to .5mm if you want those walls 1mm and don't want the additional passes. Assuming Slic3r PE and .4mm nozzle: if the parameter is set to .45, a 1mm width will require 3 passes. You can of course change the parameter to up to twice the width of the nozzle diameter…. So you could set your width up to .8mm with a .4mm nozzle (I always do this when I set “Spiral Vase” mode on). After a year of printing (2000+ hrs.) on my MK2 (w/S upgrade), I’ve settled on 1.2mm using Slic3r PE for a general minimum on exterior walls. I do use thinner walls in some cases, but I do like to keep multiples of .4mm. I would suggest you slice your model, then examine your “Platter > Layers” tab to see how many passes a wall requires. I think anything under 1mm gets a little iffy, but the MK2 at least does an excellent job even then. I am looking forward t seeing how my soon to be received MK3 compares to my MK2 in this regard. Attached picture shows a 3 pass 1.2mm wall using a MakerGeeks Maker PLA.

Select Machining Technologies has partnered with globally recognized brands of CNC machine tools designed and engineered for machining large, complex ...

Guhring is somewhat unique amongst carbide end mill manufacturers in that Guhring produces its own carbide rod, which is the substrate material for all Guhring ...

0086-813-8127573

0086-813-8127573