Dorman Upholstery Hog Rings 74365 - 74365

If you make steel tools like I do, sometimes a hard surface is in order. There is a way to case-harden steel that is inexpensive and quick and can be done with an acetylene torch as the heat source. It uses a powder called Cherry Red that is available from tool supply houses.

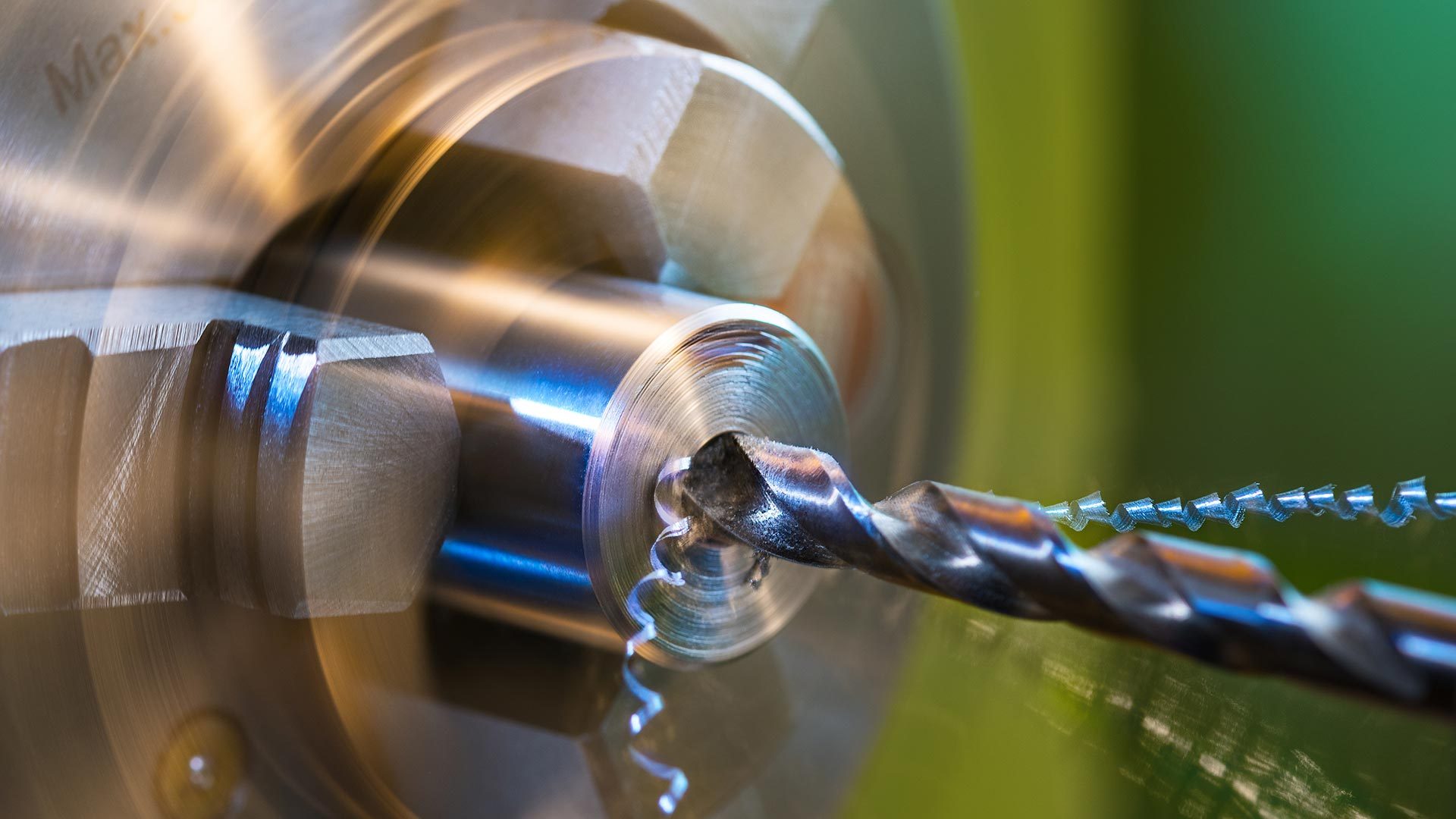

The cutting edge on a good quality cobalt bit should last for longer than a standard HSS bit. Like other HSS bits, they are corrosion-resistant, which means they should retain their condition in all storage and usage conditions they’re likely to experience. However, cobalt can be brittle. If your cobalt drill bits aren’t cared for properly or are dropped, they can break – which can prove costly.

Process of increasing the surface hardness of a part. It is accomplished by heating a piece of steel to a temperature within or above its critical range and then cooling (or quenching) it rapidly. In any heat-treatment operation, the rate of heating is important. Heat flows from the exterior to the interior of steel at a definite rate. If the steel is heated too quickly, the outside becomes hotter than the inside and the desired uniform structure cannot be obtained. If a piece is irregular in shape, a slow heating rate is essential to prevent warping and cracking. The heavier the section, the longer the heating time must be to achieve uniform results. Even after the correct temperature has been reached, the piece should be held at the temperature for a sufficient period of time to permit its thickest section to attain a uniform temperature. See workhardening.

What is hardening process in heat treatment

Cobalt bits are a combination of steel (or another alloy) mixed with a small percentage of cobalt, typically between 5 – 7%. Cobalt has a melting point of 1495°C and a boiling point of 2927°C, which makes it perfect for use at high temperatures. By combining a small amount of cobalt with another alloy, the results are incredible.

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.

Hardened steel material list

Over time, HSS drill bits can become blunt and need to be sharpened, which demands specialist tools that aren’t always available. If you’re using HSS drill bits for long periods or at high RPMs, you may need to use cutting fluid to keep the bit cool.

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

The strength of cobalt means that drill bits are better suited to the tough challenge of cutting through steel. Cobalt bits aren’t suitable for general applications. For less intensive operations, like drilling through wood, plastic or light metals, an HSS drill bit is perfect.

The process causes a layer of the compound to become stuck on the steel, but it is water-soluble and so not too hard to remove. The compound dissolved in water is alkali and can irritate skin, so it’s a good idea to use rubber gloves and flush with plenty of water.

Types of hardening process

Brandt Taylor is owner of Berlin, Massachusetts-based Taylor Engineering, a machine shop and manufacturer of lathe chuck jaws.

2. Coat the red area with the heat-treating compound. When I do the end of a punch, I put some compound in a tin can and plunge the tool in. Use a well-ventilated area or, better yet, do it outdoors because it gives off ammonia fumes when the compound is heated. Cherry Red comes in a plastic container, so don’t put hot metal in the container. And take care because the compound can irritate skin.

How tohardensteel with oil

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

Types of hardened steel

Process that combines controlled heating and cooling of metals or alloys in their solid state to derive desired properties. Heat-treatment can be applied to a variety of commercially used metals, including iron, steel, aluminum and copper.

HSS bits are hardwearing and heat resistant. The large concentrations of chrome and nickel in stainless steel ensure that HSS bits are super strong and durable. HSS drill bits are capable of safely drilling through hardwood, some metals and plastic. They’re safe to operate at high speeds (RPM) and provide long-lasting performance – as long as they are maintained.

They are most often used to cut through hardened and abrasive materials. Cobalt bits are able to cut through the most hardened metals, including bronze, cast iron, stainless steel and titanium. They are also able to cut through weld seams.

Harden metalcrossword clue

The picture on Page 10 shows what is needed: a container of Cherry Red; two tin cans — one to hold the compound and one for the quench; pliers to grab your part; and a spoon to coat the part if that’s appropriate. You also need an acetylene torch. Plan your process beforehand, and check to see that everything will work smoothly. You want the part to be bright red when coated by the hardening compound. You’ll be dealing with hot stuff, so having a plan is worthwhile.

If you’re unsure of the equipment you need, then speak to us. At R.D. Barrett we’ve been supplying the public and the trade with high-quality tools since 1975. We’re always happy to answer any questions you might have, and give you the benefit of our experience to ensure you have the right tools to do the best job.

How tohardensteel with a torch

It’s crucial for the safety of your tools and yourself that you use the right bit for the job. You will find cobalt drill bits stocked alongside other popular choices, including titanium coated, titanium nitride and tungsten carbide bits. Each of these has its strengths and weaknesses which you should be aware of before buying.

Years ago, there were compounds to do this that had cyanide in the mix. You sure don’t want that. Cherry Red has no cyanide, but you don’t want to eat the stuff or get it in your eyes. Like every process at a metalworking shop, you have to be reasonable about safety.

R.D. Barrett was established in 1975 by Ron Derek Barrett, an ex employee of both DS & G Lathes and Ford Motor Company. We hold one of the UK largest stock of engineering tooling.

Sturdy, hardwearing and robust, modern metal drill bits can cut through the toughest materials with no trouble. When it comes to drilling, selecting the right tool for the job is crucial. In this article we describe the difference between High-Speed Steel (HSS) and cobalt drill bits, their strengths and weaknesses, and when you should use them.

Cobalt drill bits are incredibly strong. They can be operated at much higher speeds than a standard HSS drill bit. The ability to withstand heat means that cobalt bits perform for long periods without cooling or the need for cutting fluid.

The heat treater that I use has a lot charge of $150. If I want a case on the end of a punch that is 0.75" dia., I can do that with my acetylene torch for about $5 of material and 10 minutes of time. I like those numbers.

How tohardensteel at home

HSS and cobalt drills need to be cared for and maintained to ensure they deliver consistent performance. Even the hardest wearing materials can become blunted or dulled after a period of hard work. Using the correct drilling technique improves the lifespan of any drill bit.

I use a heat-treating company to do the work if the part requires a certain depth of the case and hardness. For example, I get parts that require a case 0.003" to 0.005" thick and 62 HRC. I would not try to do that with the Cherry Red process, but if I make a tool or die for in-house use and want a case with an HRC above 55, then I’ll use it.

0086-813-8127573

0086-813-8127573