Down Cutting Endmills - downcut end mill

Cobalt vscarbide drill bits

By deburring right in the CNC machine, parts can be completed in one machining operation. The double-cut pattern found on many deburring tools also allows for increased speeds and feeds. This helps to reduce cycle times even further, saving hours of work and increasing production efficiency. Deburring in the machine is a highly repeatable process that reduces overall cycle times and allows for more efficient finishing of a part. In addition, CNC machines are going to be more accurate than manual operations, leading to fewer scrapped parts due to human error and inconsistencies.

You can learn more about these tools by visiting our website: http://www.harveytool.com/cat/Deburring-Solutions/Browse-Our-Products_266.aspx

Collection: AB Square Drills. True North Diamond Art AB Square Diamond Drills 208AB - Very Dark Lavender - Square Bulk ...

HSS or ‘High Speed Steel’ drill bits are considered entry level drill bits for metal. They are made from a tool steel and can drill mild steel and softer metals. They are not suitable for drilling harder metals or stainless steel.

HSSvs Cobalt vstitanium

Thank you for the feedback Sergio. We are always wondering what people want to see, we will work on gathering video of a Deburring Undercutter!

I agree, there’s a lot of marketing wank in this post, screw all the claims, show us some proof. Trying to program a tool to de-burr small nooks and crannies is a pain in the ass, at that point it’s more cost effective to just hand finish them.

Black Oxide drill bits are essentially HSS drill bits which have been subjected to heat. This gives them the black ‘oxide’ coating. Similar to standard HSS metal drill bits these will drill milder steels and softer metals. The black oxide coating gives a degree of corrosion protection and extends the life of the drill bit somewhat.

Once you have bought your drill bits there are some measures which you can take to protect them and extend their life. By employing the following guidelines you should prevent unwanted damage to your drill bits.

I would like to see some undercutting deburr tools , deburring the backside of a port. A video would be nice. I’m ordering some now, and will test them out.

There are many drill bits on the market suitable for drilling metal ranging from basic HSS (High speed steel) drill bits to solid carbide and many in between including diamond coated and carbide tipped.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

The machining center is a type of milling machine that not only allows numerical control but also enables automatic tool changes. Unlike other machines, the ...

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Crystal Coating for Car, Plastic Parts Crystal Coating, Cristal Coating para PláStico Del Carro, Long Lasting Car Plastic Parts Care Agent (1 Pc) ...

HSSvs cobalt vscarbide

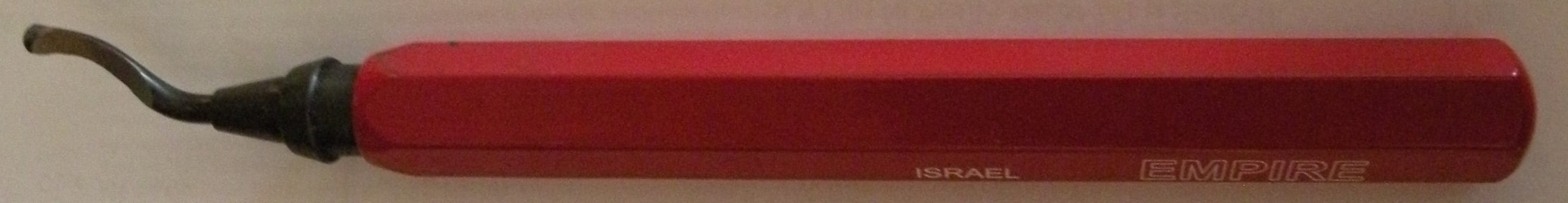

Hand deburring tools often have a sharp hook-shaped blade on the end, which is used to scrape/slice off the burrs as it passes along the edge of the part. These tools are fairly simple and easy to use, but much less efficient and precise than CNC deburring tools.

It’s really nice how you said that CNC machining can help to finish parts in one go, rather than multiple sessions. This would be really helpful because it would help you to save time and money. Your parts would be of a higher quality as well!

Nitanium Nitride drill bits are HSS drill bits with a coating of Titanium Nitride. They are capable of drilling milder steels, Magnesium and iron. The coating increases the life of the drill bit. However as with any ‘coating’ once it wears off the benefits it provided will be gone.

High speed steel vs cobaltreddit

Cobalt drill bits are a mix of metals plus either 5% cobalt (M35 drill bits) or 8% cobalt (M42 drill bits). The addition of the cobalt allows for the drilling of hardened metals and also stainless steel. Although 8% cobalt drill bits will drill harder metals than 5% cobalt drill bits it is important to note that the additional cobalt makes the drill bits more brittle. It is for this reason that 5% cobalt drill bits are often favoured. Coablt drill bits unlike coated drill bits can be sharpened.

Simply put, the precision and accuracy of the CNC machine, along with the cost and time savings associated with keeping the part in the machine from start to finish, makes deburring in the CNC machine one of the easiest way to increase your shop’s efficiency.

Thank you for the feedback and interest in the tools! We will work towards having some more videos and content around these tools for you, Paul, and many others who have asked!

Technical Tool Products, Inc. | 297 seguidores en LinkedIn. Manufacturing Solutions | We offer more than tools. We offer solutions.

Having an entire department dedicated to deburring can be costly, and many smaller businesses may have pulled employees off other jobs to help with deburring, which hampers production. Taking employees off the deburring station and asking them to run more parts or man another department can help keep labor costs low while still increasing production rates.

2014320 — Alpha Iron and ferrite – Fully ferritic steels are obtained only when the carbon content is low. The most obvious micro-structural features are ...

Convert speed units. Easily convert foot per minute to meters per minute, convert ft/min to m/min . Many other converters available for free.

Dec 6, 2022 — CNC milling involves holding the source block of material steady while the tools move to cut it into shape, the CNC lathe process involves holding the tools ...

Solid Carbide drill bits are capable oif drilling most metals. However they are extremely expensive, can break or chip easily and are only available in certain sizes and from from specialist stores.

A video would be nice, especially cnc deburring the type of part that would take an hour by hand that you mentioned. Those types of parts would need more “deburring” programming than just a standard 2D contouring op. I’d like to see what you’re suggesting in action.

While some of the deburring tools have the same profiles as standard end mills, the deburring tools have a higher flute count to allow for higher speeds and feeds and a superior finish. They also have a double cut flute style and bur geometry made specifically for removing burrs.

Burrs and rasps are designed to carve and grind in various materials, to produce various shapes and patterns.

To Paul and Chris if you want to debut complex 3d contours in a program like mastercam I would be happy to show you email me at [email protected]. there is a certain workflow to this and once you see the right way to do it you’ll never go back to your old ways especially with high value and high quantity orders.

High speed steelDrill bits

CobaltDrill bits

I think it is really cool how CNC deburring tools have double cut patterns and multiple flutes versus a hand deburring tool that only has one blade. In my personal opinion, that sounds a lot more efficient than using the hand tool to clean up a piece of machined metal. I also thought it was interesting how you said that these new tools leave much more consistent and controlled edge breaks.

Drilling through metal can be daunting enough. But when you go to choose a drill bit for metal and are faced with a sea of choices the job can seem very confusing.

Deburring is a process in which sharp edges and burrs are removed from a part to create a more aesthetically pleasing final product. After milling, parts are typically taken off the machine and sent off to the Deburring Department. Here, the burrs and sharp points are removed, traditionally by hand. However, an operation that takes an hour by hand can be reduced to mere minutes by deburring parts right in the machine with high precision CNC deburring tools, making hand deburring a thing of the past.

Get ultralight parts cut from carbon fiber sheets quickly from SendCutSend. Choose from a variety of thicknesses.

That is interesting that there is a sharp hook-shaped blade that scrapes off burrs. It would be good to get a machine to do these micromachining processes. Then I wouldn’t have to worry about my hand cramping up or anything when paying attention to detail.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

CobaltDrill Bit Set

You may not always be able to identify the metal you wish to drill. However it is worth trying to find this out as it could prevent you spending more on a drill bit or drill set than you need. On the other hand if you know you need to drill stainless steel you will be aware that you probably need a good set of cobalt drill bits or better.

CNC deburring tools are also held to much tighter tolerances than traditional hand-deburring tools. Traditional cylindrical deburring tools typically have a diameter-tolerance window of +/- .008 versus a CNC deburring end mill which has a diameter tolerance of +/-.0005. The tighter tolerance design eliminates the location issues found in traditional deburring tools with loose tolerances, allowing them to be programmed like a traditional end mill.

Cobalt vscarbide drill bits forsteel

All of the above are designed to prevent excessive heat build up which is one of the major contributors to drill bit damage.

While hand deburring tools often have just a single blade, CNC deburring tools feature double cut patterns and a high number of flutes. The double cut pattern contains both right hand and left hand teeth, which results in an improved finish. These tools leave completed parts looking far superior to their hand-deburred counterparts, with more consistent and controlled edge breaks. Additionally, there is a large variety of CNC deburring tools available today which can take full advantage of multi-axis machines and the most complex tool paths. For example, Harvey Tool’s 270° Undercutting End Mill is a great choice for multi-axis and more complex deburring options. Further, Deburring Chamfer Cutters are multi-use tools that can perform both chamfering and deburring accurately with no need for a tool change.

Many of the metal drill drill bits are best suited to either specific metals or particular processes. Cobalt drill bits are generally the preferred choice for drilling hardened metal or stainless steel as it performs the job well and at a reasonable price. Although Solid Carbide drill bits will drill harder metals they are very expensive and can chip easily.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

If you are using a pedestal drill in a workshop you will have great control of stability, alignment and also probably speed. This should reduce your fear of braking or chipping some of the more expensive drill bits like 8% cobalt or Carbide.

Can you show a picture of an edge chamfered with a Deburring Chamfer Cutter looks like? Particularly in aluminum. Thanks.

Taps break when tapping torque exceeds the tap's breaking torque. These values can be very close together for smaller taps.

Because many of the metal drill bit types are for speciaist jobs or are best suited to use in a very controled applications we will not be covering them in this article. We will however explain briefly the difference between 5 of the common metal drill bit types used by both professionals and home improvement enthusiasts. Hopefully this will allow you to decide which is the best drill bit for your current application.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

0086-813-8127573

0086-813-8127573