Download catalogues, brochure & 3D - d'andrea boring bar

Thermal cracking is a non-catalytic process that breaks heavy hydrocarbons down into smaller molecules by simply heating them to a high ...

They come with a modern computer numeric control system (CNC). You can use this control system to add a CAD/CAM program and after that, whenever you command the machine, it will start and perform the machining operation according to your program input.

A turret lathe machine is an advanced lathe machine used for mass production. It is kind of an upgraded version of an engine lathe, where the tailstock is replaced by a revolving hexagonal turret.

It reduces your workpiece load/unload time:yes, just clamp your workpiece once, and perform as many operations you want in a single setup.

PEOPLE Magazine

You see, this design makes your work a lot easier, all you have to do is simply clamp your workpiece in the chuck, perform the first operation, now rotate the turret, and perform the second operation. You can repeat the process as long as you want.

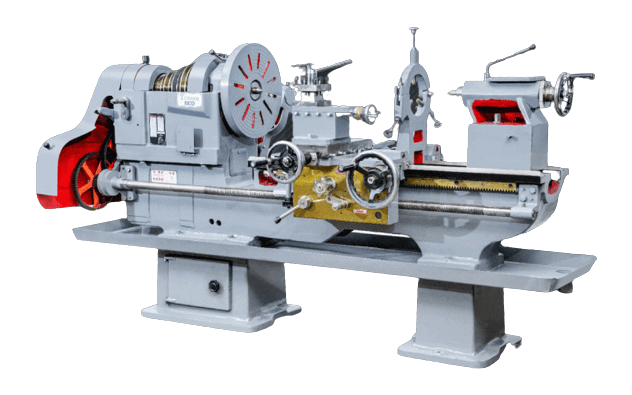

Nowadays the machine is driven by an electric motor but back in the 19th-century people used steam engines to drive the machine. That’s why it is called an engine lathe machine even it does contain an engine nowadays.

It is also called center lathe machine, because back then almost all machine tools were driven by either separate engines or central engines.

An automatic Lathe machine comes with a group of mechanisms that makes it capable of changing and feeding cutting tools automatically.

A human or an automated machine feeds the workpiece into the path of a rotating cutting blade to remove chips of excess metal. This process may occur on a ...

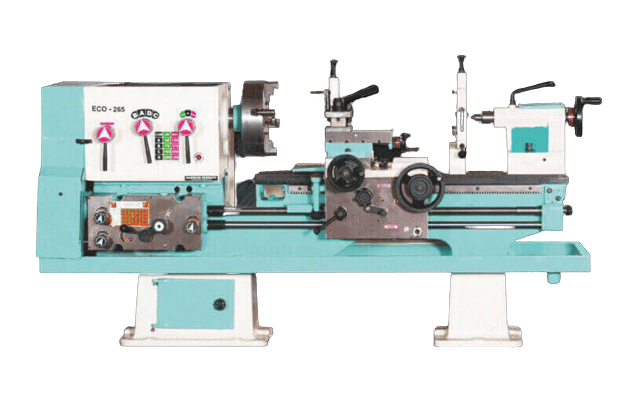

If you have a light job that requires lathe machine operations such as turning, facing, grooving, parting, threading, drilling, boring, knurling, and tapping, this machine is for you.

Entertainment news

This type of lathe machine is used for woodworking and metalworking. You can perform various machining operations on this lathe machine… such as turning, facing, grooving, knurling, threading, drilling, boring, reaming, and many more.

E! News

This is a special breed of lathe machine mostly used to make precision parts and tools such as die, gauges, jigs, and fixtures.

Sep 14, 2024 — ZX Modular Boring Tools (MBT) offer versatility and economy when machining bores, counter-bores, tapers, threads, and complex contours ...

A bench lathe machine is a small-size, hand-operated power lathe, mainly used for small precision work. It looks very similar to speed lathe machines.

In this turret, you can set up multiple cutting tools (usually up to 6 tools), such as drilling, countersinking, reaming, tapping, etc.

Access Hollywood

Reamers are rotary cutting tools with one or more cutting elements used to enlarge to size and contour a previously formed hole.

I hope you liked it. Feel free to share this post… and… if you have any questions related to lathe machine types––you can ask us simply by filling out the contact us form.

People

Et online

Sep 26, 2024 — Top 10 on-premise Data Catalog Tools in 2024: Open Source Tools like Apache Atlas, OpenMetadata, Metacat.

Due to their high-speed spindle, speed lathe machines are used for woodturning, furniture making, metal polishing, spinning, and centering.

MSC carries a variety of counterbores and counterbore tools including counterbore pins, counterbore pilots and more. Shop counterbores by type, ...

This page introduces the formulas for calculating cutting speed. The figures obtained from the calculations are for reference only.

A Speed Lathe Machine is a high-speed, hand-operated lathe machine, mainly used by woodworkers. It can provide a spindle speed from 1200 to 3600rpm.

You have successfully unscrambled your letters! You found 101 words by unscrambling the letters, ETSHOW. The above results will help you advance to the next round in Text Twist, Super Text Twist & Text Twist 2. Tip: Did you know you can unscramble multiple words, phrases or even a sentence? The instructions, and an example are below.

Play TextTwist free on one of above game sites or download TextTwist to your PC or Mac and Try our TextTwist Word Finder and you will never get stuck again.

Us Weekly

Entertainment Tonight hosts

When you have a job that is complicated precision operations, requires skills, and you have to produce it in mass quantity… this machine is suitable.

You can guess by the name, special purpose lathe machines are custom-tailored lathe machines to suit particular needs. They are mostly used for heavy-duty jobs, where regular lathes can’t be used, or using regular lathes can be costlier or time-consuming.

Eastman Machine Company's hand cutters are designed to cut straight and intricate patterns from textiles, fabrics, and composites manually.

Rison Titanium Adjustable Wrench 5.9"/150mm Multi-Tool EDC Wrench,Ultralight Portable,Suitable for Different Fasteners Sizes by Adjusting the Opening Size.

Okay, so that was all the information that you might want to know about the types of lathe machines used in workshops and toolrooms.

May 19, 2022 — PVD and CVD coatings are highly efficient methods for coating the surfaces of materials, components, and machinery in industrial settings.

It looks similar to an engine lathe machine. But it is made from more accurate and precise parts than an engine lathe machine. Thus, the price of a toolroom machine is higher than an engine lathe machine.

Many people think that you don’t need special skills to operate this machine, however, no one should operate this machine without proper training, it is a very expensive machine, and with a new operator, the chances of an accident increase.

0086-813-8127573

0086-813-8127573