Download CNC Speed And Feed Machinist Calculator - milling speeds and feeds calculator

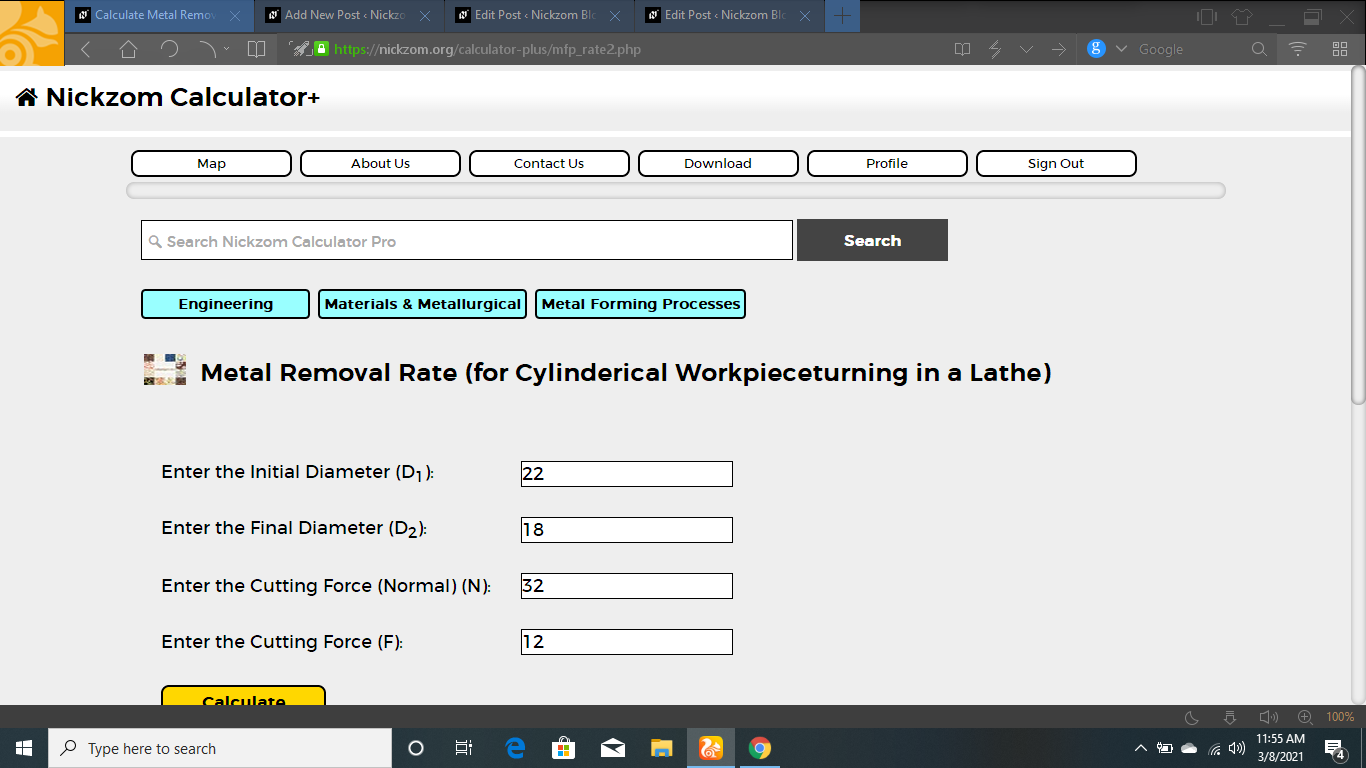

Now, enter the value appropriately and accordingly for the parameter as required by the Initial Diameter (D1) is 22, Final Diameter (D2) is 18, Cutting Force (Normal) (N) is 32 and Cutting Force (F) is 12.

Today, carbide inserts are produced in different classifications to offer reliable, consistent performance for various materials or applications. Carbide inserts are particularly appropriate when wear is an issue. The exceptional hardness and stability of tungsten carbide allows machining to meet very exacting tolerances while at the same time minimizing equipment wear. Plus, carbide inserts are more resistant to abrasion at high or low temperatures, ensuring cost-effective performance over the lifetime of the insert.

Wholesalecarbide inserts suppliers

Unlock solutions for every math, physics, engineering, and chemistry problem with step-by-step clarity. No internet required. Just knowledge at your fingertips, anytime, anywhere.

Carbide insertschart

When it comes to performance under pressure, tungsten carbide inserts can take the heat. This durable, extremely strong metal is made by cementing grains of tungsten carbide into cobalt or nickel. The result is exceptional hardness, second only to the diamond. In fact,

Our wide selection of indexable carbide inserts offers you multiple cutting edges that can be changed easily for optimal economy, tool life, productivity and precision.

To get access to the professional version via web, you need to register and subscribe for NGN 2,000 per annum to have utter access to all functionalities. You can also try the demo version via https://www.nickzom.org/calculator

Usedcarbide inserts suppliers

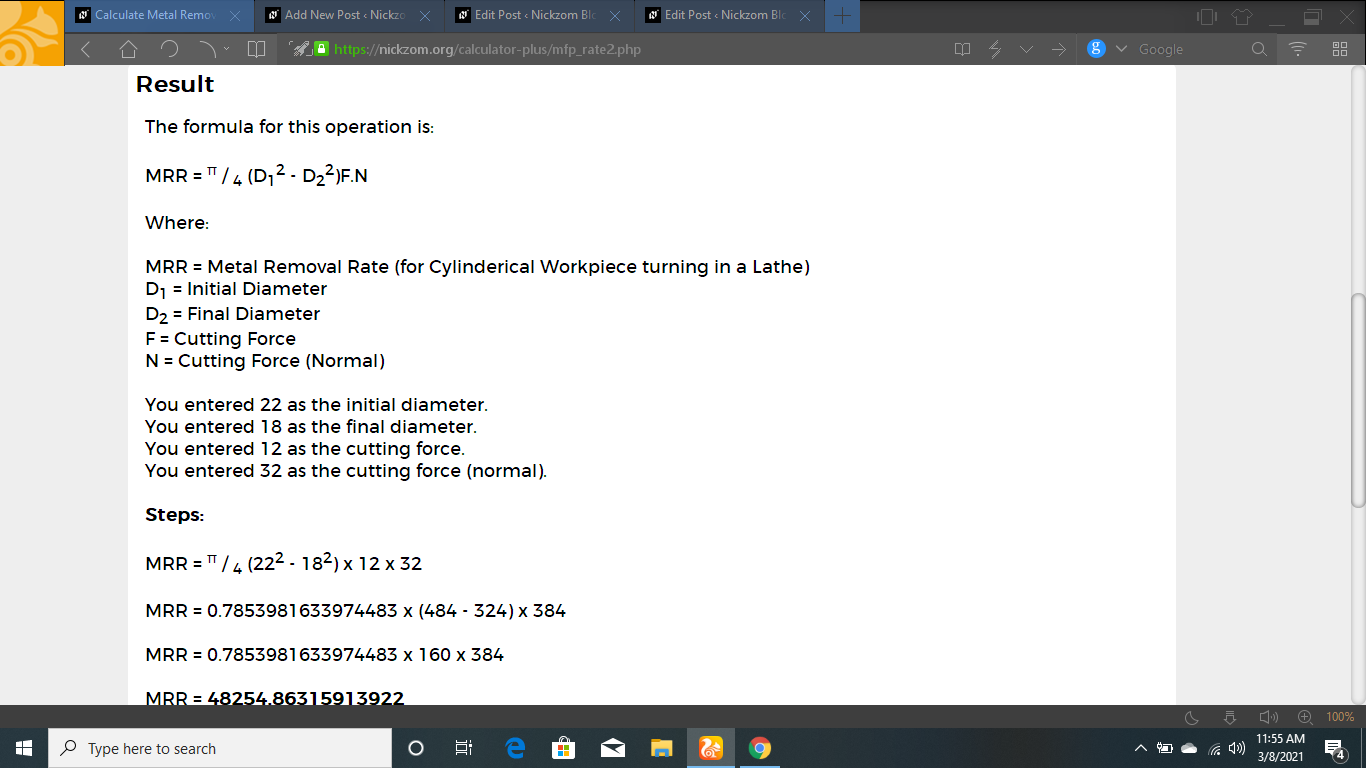

As you can see from the screenshot above, Nickzom Calculator– The Calculator Encyclopedia solves for the metal removal rate (for cylinderical workpiece turing into a lathe) and presents the formula, workings and steps too.

Carbide inserts suppliersusa

We provide comprehensive educational resources tailored to mastering complex calculations and enhancing school education. With years of expertise and a proven track record, our platform delivers authoritative, reliable content designed by educational experts. Trust us to empower your learning journey with clarity and precision, making difficult subjects accessible and engaging for all students.

Tel: (800)-445-1068 Email: sales@hemlytool.com Billing: P.O. Box 241 Billing: Thompson, OH 44086 Shipping: 16600 Thompson Rd

Ultra metcarbidegrades

MRR = π / 4 (D12 – D22)F.N MRR = π / 4 (222 – 182) x 12 x 32 So, MRR = 0.78 x (484 – 324) x 384 MRR = 0.78 x 160 x 384 MRR = 48254.8

To get the answer and workings of the metal removal rate (for cylinderical workpiece turning into a lathe) using the Nickzom Calculator – The Calculator Encyclopedia. First, you need to obtain the app.

Carbide inserts suppliersnear me

Imagine every complex calculation—Math, Physics, Chemistry, Engineering—solved with ease. Nickzom Calculator+ guides you step-by-step through formulas and conversions, showing you exactly how it's done. From simple to advanced, this app has what no one else offers: instant answers with solutions laid out clearly, all offline.

Carbideinsert identification chart PDF

it is this hardness that led to its use beginning in the 1920s and through World War II. Following the war, as cementing processes were honed, tungsten carbide became an indispensable material for use in manufacturing, mining and other industries.

The image above represents metal removal rate. To calculate metal removal rate (for Cylinderical Workpieceturning in a Lathe), two essential parameters are needed and these parameters are Initial Diameter (D1), Final Diameter (D2), Cutting Force (Normal) (N) and Cutting Force (F).

Korloy is one of the industry's leaders in cutting edge tool technology. Manufacturing both tool bodies and inserts, Korloy has the expertise to provide excellent tools.

Bestcarbide inserts suppliers

As an industry-leading manufacturer of cutting tools, WIDIA offers a complete portfolio of precision-engineered products and custom solution services.

Android (Paid) – https://play.google.com/store/apps/details?id=org.nickzom.nickzomcalculator Android (Free) – https://play.google.com/store/apps/details?id=com.nickzom.nickzomcalculator Apple (Paid) – https://itunes.apple.com/us/app/nickzom-calculator/id1331162702?mt=8 Once, you have obtained the calculator encyclopedia app, proceed to the Calculator Map, then click on Materials and Metallurgical under Engineering.

MRR = Metal Removal Rate (for Cylinderical Workpiece turning in a Lathe) D1 = Initial Diameter D2 = Final Diameter F = Cutting Force N = Cutting Force (Normal)

From milling and turning to grooving and threading applications, Hemly Tool Supply offers a wide array of quick-change, indexable carbide inserts with multiple cutting edges for optimal economy, tool life, productivity and precision â regardless of your application. Order online or contact us today for friendly, expert advice.

Nickzom Calculator – The Calculator Encyclopedia is capable of calculating the metal removal rate (for cylinderical workpiece turning into a lathe).

Hemly Tool stocks over 1 million carbide inserts to meet your machining needs. We carry a full stock of turing, milling, and threading inserts. Contact us today to see how we can help.

The screenshot below displays the page or activity to enter your values, to get the answer for the metal removal rate (for cylinderical workpiece turning into a lathe) according to the respective parameters which is the Initial Diameter (D1), Final Diameter (D2), Cutting Force (Normal) (N) and Cutting Force (F).

Let’s solve an example; With an initial diameter of 22, a final diameter of 18, a cutting force of 32 and a cutting force of 12. Find the metal removal rate?

0086-813-8127573

0086-813-8127573