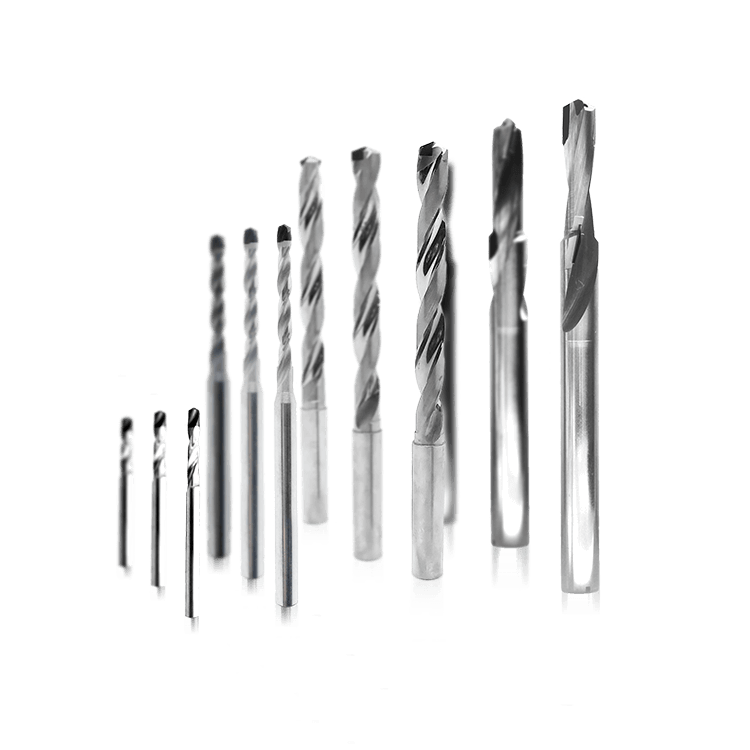

Drill & Driver Bit Accessories - tiny drill bits

We use the latest new material CHEVRON to braze on the top of the carbide body, then machine the tool body and the PCD area at one time by the electrical discharging process, which makes the tools have a good consistency. These drills are widely used in the new composite material, such as aluminum alloy, Sic, carbon fiber, PMMA, plastic, and so on

We tipped PCD on the top and chamfer of the drills, this kind of PCD step drill can locate directly the position of the holes and drill the 45° or 60° chamfers correctly, it helps workers to reduce working difficulties and workload. According to clients different requirement for the material or holes, we can add double outlets to lower the impacts from chips when machining.

The top of the PCD solid nib is formed with special PCD material, it is developed specifically for the drilling of composites and composite/Stack/AL/Ti applications, Because of its solid nib top, the PCD solid nib has strong resistance to cracking and chipping and the stability of the tool is significantly improved.

PCD diamond brazed-on entire end of solid carbidebody allows to increase tool life over carbide, meanwhile, the internal spiral coolant can provide many benefits that save both times and offer better tooling life, By reducing the temperature of both the drill and the drilling service and increasing lubricity, the tool is subject to decrease wear and tear.

We are dedicated to developing every drill, and our PCD drills and step drills are widely used for drilling aluminum, magnesium, wood, plastics, CFRP, GRP, and new composite materials. They show excellent wear-resistant properties when machining highly abrasive materials and offer an extremely long tool life compared to traditional carbide drills.

We manufacture a complete range of PCD(Tipped or solid nib) drills and step drills for both rough hole processing and finishing cuts. We have developed a variety of pointed geometries to cover all possible applications when drilling pre-cast, through, or blind holes. However, there are still other factors to consider, such as hole depth, wall thickness, and interrupted or non-interrupted cuts.

0086-813-8127573

0086-813-8127573