Drill Bits - machinist drill bits

This article was written by engineers from the BOYI team. Fuquan Chen is a professional engineer and technical expert with 20 years of experience in rapid prototyping, mold manufacturing, and plastic injection molding.

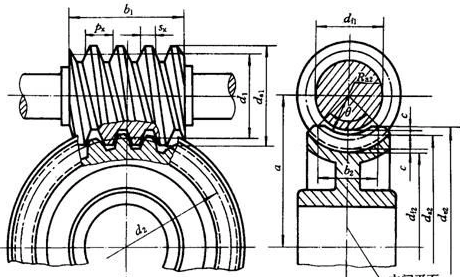

Lead angleof worm gear

Choose your class below for more information and to register. A range of dates and times are available.

This is very much a feature to let you evaluate if you want to sign on for the paid version. So why is it here? Every day we see posts from people confusing this trial offer with the free personal license version so it is mentioned here to ensure the point of difference between the trial and personal use license versions is known.

While helix angle and lead angle share similarities in their association with helical structures, they serve distinct functions in machining operations. Understanding the disparities between these angles is essential for optimizing machining processes, ensuring precision, and achieving desired performance outcomes in manufacturing applications.Or learn more about CNC machining information

In the process of designing threads, selecting the helix angle or pitch angle involves considering multiple factors, including usage scenarios, functional requirements, machining, and assembly conditions. Here are some guiding principles and recommendations:

Branching out on your own? You also have the option to apply for the Fusion 360 for Startups program, which provides eligible startups with a free, one-year license for Fusion 360. This removes any limitations imposed on the personal use version.

Join our newsletter for exclusive FREE content including live webinars, video lessons and discounts on courses.

Send this link to your mates to get $50 OFF their first course. If they enroll we will email you a discount too.

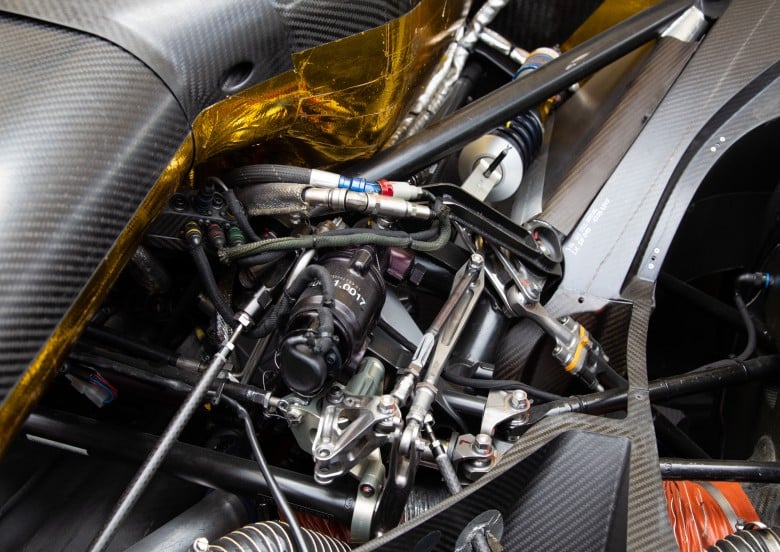

In simple terms, it's great software you can use to 3D model custom parts you cannot buy 'off the shelf' for your race car, hotrod, track car, jet boat, motorbike or whatever it is you are working on, by using skills like those taught in the 3D Modeling & CAD for Motorsport course.

Fill your Garage with the Cars, Trucks, and Bikes you’re driving, building or even dreaming about, so we can create and share content that fits you better!

If you are interested in getting Fusion 360 for free, there are a few options available to you for both personal and startup (business) use.

Threadlead angle calculator

Helix angle and lead angle play important roles in thread size design and mechanical calculations, with main differences reflected in their definitions, functions, and measurement methods.

If you're still unsure, enrol anyway. If it's not for you, simply tell us and we'll quickly refund every cent. It's that easy

Lead anglevs helixangle

The main difference between thread angle and helix angle is their focus: thread angle pertains to the angle formed by the flanks of the threads on a threaded component, while helix angle refers to the angle formed between the helical path of a cutting tool or structure and its axis of rotation during machining operations.

BOYI provides expert CNC machining and injection molding services in China, delivering quality parts quickly and efficiently from prototyping to production.

Taz is HPA’s resident keyboard monkey. Coming from a 4x4 and motorcycling background he adds to the teams already diversified range of skills and interests. In his spare time you’ll find Taz creating some noise pollution on his WR450F, drum-kit or loudly snacking.

Threadangleformula

In machining, the lead angle is commonly used to describe the motion trajectory of the tool during thread cutting or helical machining. The size of the lead angle depends on the feed rate and rotational speed of the tool, as well as the geometric shape of the workpiece.

In the realm of machining and engineering. Two critical parameters that often come into play when discussing cutting tools, particularly in the context of threaded components, are the helix angle and lead angle. While they both pertain to the angular orientations of tool features, they serve distinct purposes and possess unique characteristics. Let’s delve into these differences to gain a clearer understanding.

With a few different ways to obtain Fusion 360 for free, including a free 30-day trial, a free 3-year personal usage license, and a free 1-year business/startup license it seems like a no-brainer to dive on in and use this tool to start building your 3D modeling skills today. If you are new to CAD or are self-taught and have hit some stumbling blocks, the 3D Modeling & CAD for Motorsport course might be the perfect accompanying tool to help you take things to the next level, setting you up with what we consider must-have fundamental know for what comes beyond that in the future too as your projects become more and more advanced.

To apply, you will need to go to the Fusion 360 for Startups home page here and fill out an application form. Once your application is received, you will receive an email with your application status and instructions on how to proceed if accepted.

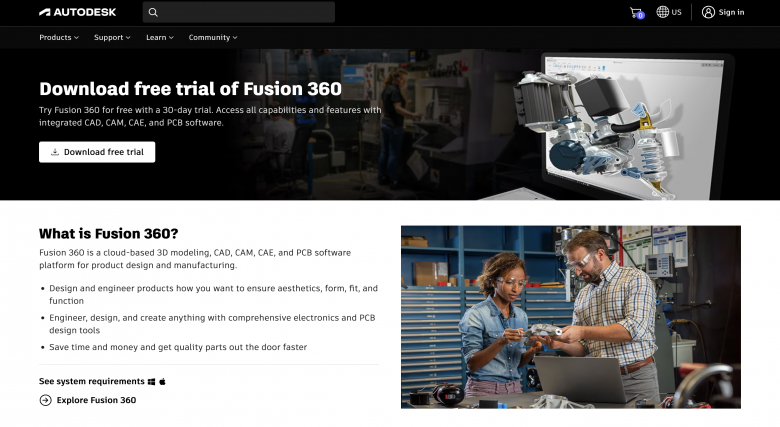

Lead angle calculatormetric

Autodesk Fusion 360 is a cloud-based 3D modeling, CAD, CAM, CAE, and PCB software platform for product design and manufacturing. It allows you to design and engineer products in a way that ensures aesthetics, form, fit, function and also provides comprehensive electronics and PCB design tools to engineer, design, and create anything while saving time and money.

Helixangleformula

BOYI possesses advanced machining equipment and an experienced technical team capable of meeting various complex machining needs. Through BOYI’s CNC machining services, you can experience the precision, quality, and efficiency of all machining projects.

The lead angle, also known as the pitch angle or thread angle, in contrast to the helix angle, the lead angle primarily pertains to the geometry of threaded components, such as screws, bolts, and taps. It represents the angle between the helix of the threads and a line parallel to the axis of the threaded feature.

The lead angle is calculated by the ratio between the feed rate and the rotational speed of the tool. It is typically expressed in degrees (°) or radians (rad).

Unified Extra Fine Thread (UNEF):Minimum thread diameter (inches): #000 (0.019685 inches) to 4 (0.250 inches)Maximum thread diameter (inches): #000 (0.029528 inches) to 4 (0.29528 inches)Pitch (threads per inch): Extremely fine, typically used for applications requiring higher precision and smaller clearances.

Fusion 360 offers a personal license (formerly known as Fusion 360 for hobbyist use) for qualifying individuals for non-commercial use.

Lead angleof thread

To obtain the free version of Fusion 360 via a personal license, click here and create your account then download the software. It's that easy.

Designers need to balance the advantages and disadvantages of lead angle and helix angle based on specific application requirements and design considerations to select the most appropriate parameters for achieving the optimal design outcome.

The helix angle is a fundamental property of helical tools, such as drills, end mills, and taps. It refers to the inclination angle of the helical line on a rotating object. In mechanical engineering, the helix angle is commonly used to describe the geometric characteristics of components such as helical gears, twist drills, and threads. The calculation of the helix angle is typically done by measuring the angle between the helical line and the axis. Its units are usually degrees (°) or radians (rad).

The personal-use license is free and valid for three years, after which you can request a renewal. To qualify for the personal-use license, users must generate less than USD 1,000 in annual revenue and use the software for home-based, non-commercial projects only. There are some limitations to this version of the software but for 3D modelling purposes, in our opinion, it is feature rich compared to other popular free options and the limitations are not 'project breaking' We highly recommend anyone new to CAD starts with this license.

Another option is to download a free 30-day trial of Fusion 360 from the Autodesk website. This trial will give you access to the software's integrated CAD, CAM, CAE, and PCB tools. You can also request a demo or talk to an expert for more information.

The advantage of a helix angle lies in its ability to facilitate efficient chip evacuation, reduce cutting forces, improve surface finish, and enhance tool stability during machining operations.

Your startup (or business using pre-2010 English) must be under 3 years old, have 10 or fewer employees and generate an annual gross revenue below US$100,000. You must design or manufacture original physical products and be willing to share your business story (note, that doesn't mean your IP!) with a valid website, transact on social media or a digital platform.

Helixangle calculator

That said, if you are at the end of your 3-year personal use license and are looking at perhaps starting to do some commercial work with Fusion 360, then this is something you should consider looking at. You can find it here. If not, then just renew your personal license.

This can be an excellent way to ease your way towards a full license if you have built up your skills and do decide to offer your services at a commercial level, and as you would expect, there are some catches.

By carefully selecting and adjusting these two parameters, the performance and reliability of the thread can be optimized to meet different design requirements and usage scenarios.

In practical applications, the size of the helix angle affects the performance and operational characteristics of rotating components. For example, in helical gears, the choice of helix angle influences transmission efficiency, noise levels, and load-bearing capacity. A larger helix angle typically implies larger tooth clearance and lower transmission efficiency, while a smaller helix angle generally has higher transmission efficiency and tighter meshing.

Unified Fine Thread (UNF):Minimum thread diameter (inches): #00 (0.036 inches) to 12 (0.750 inches)Maximum thread diameter (inches): #00 (0.086 inches) to 12 (0.794 inches)Pitch (threads per inch): Finer than the corresponding UNC threads, typically used for applications requiring higher precision and tighter fits.

Unified Coarse Thread (UNC):Minimum thread diameter (inches): #0 (0.060 inches) to 4 (0.437 inches)Maximum thread diameter (inches): #0 (0.094 inches) to 4 (0.484 inches)Pitch (threads per inch): Varies from coarse to fine depending on specific sizes.

The lead angle of a helical gear is the angle formed between the tangent to the helix and the gear’s axis. It determines the axial movement of the teeth during one complete revolution of the gear. In contrast, the helix angle of a helical gear is the angle between the helix’s tangent and the gear’s axis, defining the helical shape of the gear teeth. Both lead angle and helix angle play crucial roles in the operation and performance of helical gears, influencing factors such as load distribution, smoothness of operation, and noise levels.

0086-813-8127573

0086-813-8127573