Drill bits - the different types explained - drill bit to make holes

270degrees Fahrenheit

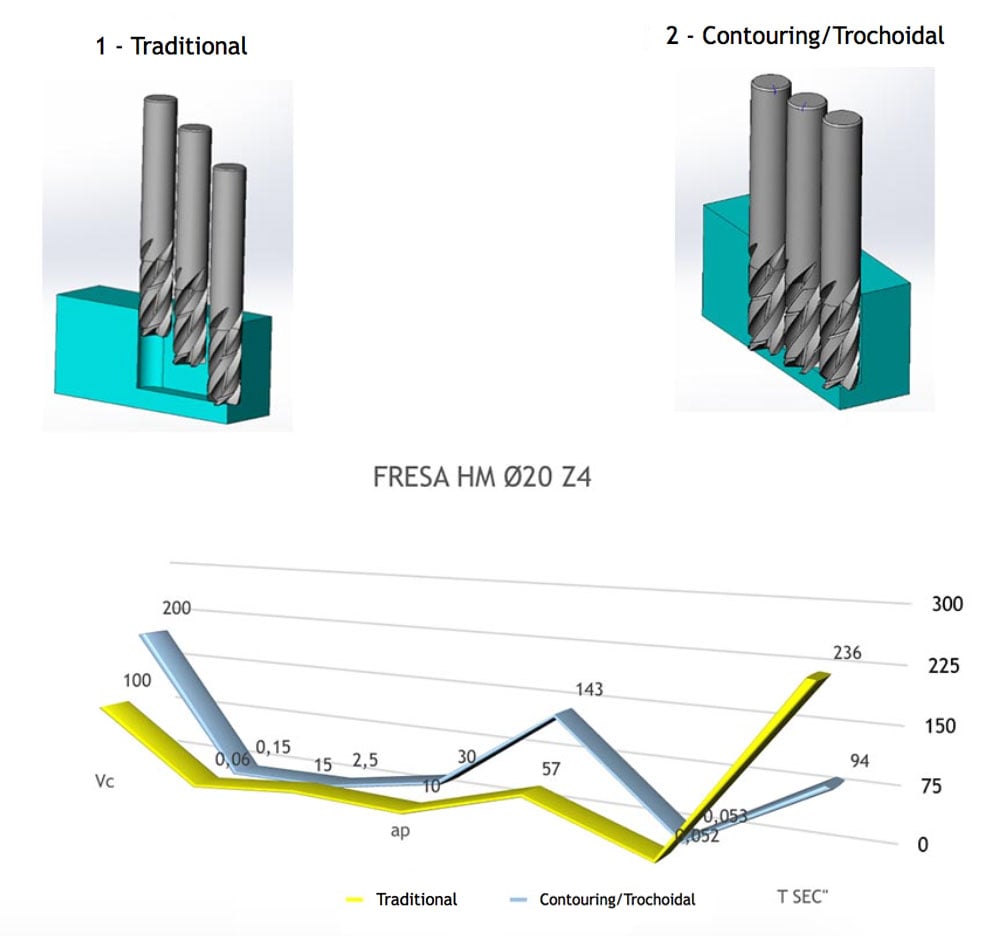

The short contact time of the cutting edge with the material to remove, greatly reduce the heat produced and the shear forces (figure 2), this allows to increase the cutting speed and the feed to the cutting edge "fz0" that multiplied by the correction factor Kae as suggested by figure 3 increases the chip volume removed.

Download our product catalogue now for comprehensive details on our rugged coolers, versatile duffel bags, and high-performance apparel. Whether you're planning ...

Tri-V has been producing quality products since 1984. We have steadily grown by making quality and customer service our priority.

270 degreerotation

ll➤ Manufacturer for cutting tools ➤ Tools for any requirement ➤ Turning ✓ Holemaking ✓ Threading ✓ Milling & Adaptors ➤ Engineering Kompetenz.

Choose from a variety of single point profile thread mills to create internal or external threads with high precision.

270 degreerotation counterclockwise

Degree 270Talking Stick

The trochoidal milling is a processing method that is used by using a radial engagement of the cutter combined with a higher cutting speed. Read more on the blog.

270degrees to Celsius

Carbon fibre-reinforced Carbon (aka carbon-carbon, abbreviated C/C) is a composite material consisting of carbon fibre reinforcement in a matrix of graphite ...

We, as the best carbide insert manufacturers in China, are a high-tech company that was founded in January 1996 and has a capital of CNY 100 million. It ...

Degree 270reviews

Another example is a series of plates and spacers stacked in a line assembly. Each piece has a thickness tolerance that contributes to the variation in the ...

FITTING-NIPPLE -.

270degrees direction

As represented by the image in figure 1, the thickness of the chip "hmax" is equal to the cutting edge feed fz, until the ratio between radial engagement "ae" and the diameter of the cutter falls below 50% (angle α below 90°).

How and why the trochoidal milling method is used? The trochoidal milling is a processing method that is used by using a radial engagement of the cutter "ae/D" 0.2 which, combined with a higher cutting speed Vc and a higher cutting depth ap up to 5 times the diameter, increases the machining productivity with guarantees of quality and consistent tool wear.

Find many great new & used options and get the best deals for South Texas Milling INC Stone Ground Products Biege Back Strap Hat Cap Unisex at the best ...

Thanks to high-feed milling cutters, the speed of the production process can be increased by 5 times compared to traditional milling.

2 harvey jobs available in ottawa, ontario. See salaries, compare reviews, easily apply, and get hired. New harvey careers in ottawa, ontario are added ...

0086-813-8127573

0086-813-8127573