Drill vs Router Bits: What's the Difference? | Blog - router drill bits

Tyre Wall Stickers Ltd t/a Robot Craftsman EU makes no representations or warranties regarding the legality or suitability of these products for road use. By purchasing these products, the buyer assumes all risks and responsibilities for any consequences associated with their use.

FaceMill Cutter

Experience consistent and repeatable performance with Mill 16™, a cutting-edge face milling solution from Kennametal. Whether you're tackling light machining or heavy-duty applications, Mill 16™ shell mills, inserts, and flanges deliver optimal results for general-purpose machining. Specifically crafted for cast iron and compacted graphite iron (CGI) machining, the high-precision periphery ground inserts have sixteen cutting edges, ensuring the lowest cost per edge and exceptional durability. The numbered cutting edges enhance ease of use and tracking. Mill 16™ milling cutters are ideal for roughing tasks on engine heads, blocks, housings, gearboxes, manifolds, and more. The Mill 16 insert features a pocket numbering system for quick set-up times. Elevate your productivity and reduce cycle time with Kennametal's Mill 16™ inserts and shell mills.

FaceMill Holder

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

The products sold on this website, including those sourced from our partners, are designed exclusively for racing and competition. These products are not intended for road use or public highways. Any use of these products must comply with the rules and regulations of officially sanctioned motorsport events. It is the buyer’s responsibility to ensure compliance with all applicable laws and regulations of their country, including but not limited to the UK and US.

Facemillinserttypes

Facemill cutter sizes

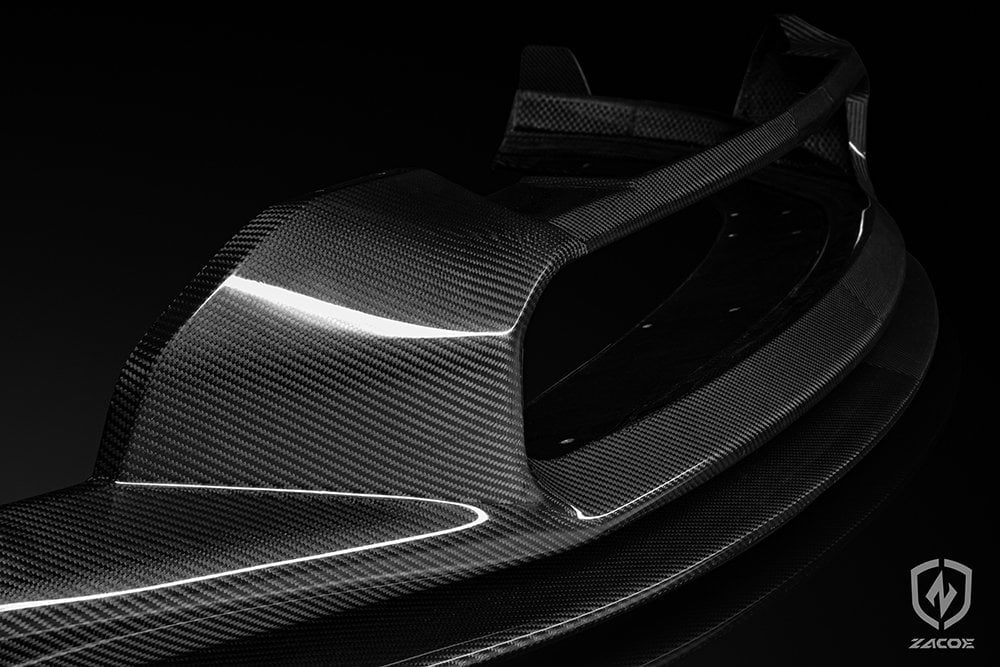

Hello, and welcome to our corner of the carbon fibre world! If you’re new here, you might be wondering about some of the terms we use, especially when we talk about CFRP and dry carbon fibre. Fear not! We’re here to break it down for you in the simplest way possible.

Now, onto dry carbon fibre. The term “dry” might be a bit misleading because it doesn’t mean the material is literally dry. Instead, it refers to the method used to make the carbon fibre parts. Dry carbon fibre is made by using a pre-preg (pre-impregnated) method where the carbon fibre is impregnated with resin before it’s molded. Then, it’s cured in an autoclave (a high-pressure oven) which makes the parts extremely lightweight and strong. Dry carbon fibre is often considered a more premium option because of its superior strength and lighter weight compared to CFRP, but it also tends to be more expensive.

So, what does this mean for you, our beloved customer? Unless specifically stated, all the carbon fibre parts we sell are CFRP. We choose CFRP for its fantastic balance of strength, durability, and cost-effectiveness, ensuring you get high-quality parts without breaking the bank. However, we also understand the unique benefits of dry carbon fibre, especially for those seeking the ultimate in performance and weight reduction. For these select items, we’ll make sure it’s clearly stated in the product description that you’re looking at a dry carbon fiber part.

First off, let’s talk about CFRP, which stands for Carbon Fiber Reinforced Polymer (otherwise known as wet-carbon). This is a type of material that combines carbon fibre with a polymer (think of it as a sort of glue) to bind the fibres together. The polymer gives the carbon fibre its shape and durability, making CFRP an incredibly strong yet lightweight material. It’s used in a variety of products and industries, from automotive parts to sports equipment, because of its high strength-to-weight ratio.

Registered Company Name: Tyre Wall Stickers Limited T/A Robot CraftsmanRegistered Company Number: 09373841Email: info@robotworks.co.ukPhone: +44 1858555583Registered Address: 45 North End, Hallaton, LE16 8UJ

0086-813-8127573

0086-813-8127573