Drilling angled holes - tool to drill at an angle

This series comes in diameters from 1/16 to 1/2 inch, and a cutting height from 3/16 to 1 inch. (As well as common metric sizes.) Longer bits will have more vibration, so always choose the shortest bit which will do the job.

Iron and steels play an important role in the world of structural and mechancial metals. Steel, in particular, is very useful because its hardness, wearability ...

However, there's a trade-off: more flutes typically mean more heat and slower material removal because the channels for chip evacuation are narrower. So, in plunge applications, 2 flutes are better.

Fewer flutes typically allow for faster material removal because there's more space for the chips to evacuate. However, the finish might be rougher compared to bits with more flutes.

With their 30 degree center-cutting mill end, and their up-cut design, Amana solid carbide CNC spiral end mills can cut metal both laterally and vertically. So go ahead, take the plunge.

Corner Rounding End Mill Metalworking Finishing End Mills · 2 FRESHLY SHARPENED HSS CORNER ROUNDING END MILLS 1/2" RADIUS NIAGARA & WELDON · 4 NEW ASSORTED HTC ...

Generally, the more flutes a router bit has, the finer the finish it will produce. This is because the bit makes more cuts per revolution. This also means each flute gets less wear.

OTR Reset Tool | International. $800 USD. View. 5.0. OTR Reset Tool | Isuzu ... © 2024 OTR Performance® Inc.. Refund policy · Privacy policy · Terms of service ...

Harbor Freight is the source for broad range of high-quality power tools. The wide selection of electric and cordless power tools at Harbor Freight are ...

Meaning. 3632/26.5. 3632/26.5- This is the Special Education/ Mental ... BUE both upper extremities. BUN blood urea nitrogen. BUR burial. Bx biopsy or ...

Collet definition: a collar or enclosing band.. See examples of COLLET used in a sentence.

Dovetail definition: a tenon broader at its end than at its base; pin.. See examples of DOVETAIL used in a sentence.

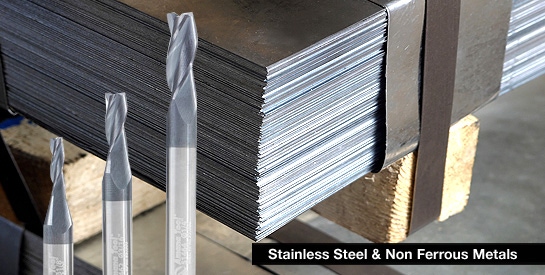

End Mill bits are typically used for metalworking, although they can be (and often are) used on wood. Choose solid carbide to handle the high rotational speeds, specific feed rates, and cutting forces involved in metal milling. An Aluminum Titanium Nitride (AlTiN) coating provides extra wear resistance and allows for faster speed rates with less heat buildup.

ANSI Size Drill Bit Chart ; Drill (in.) Decimal, Drill (in.) ; 80 .0135, 1/8 ; 79 .0145, 30 ; 1/64 .0156, 29 ...

You can cut slots by starting at one end of the material and cutting across, or use an end mill for profiling along the peripheral edge of the material.

The AlTiN coating, along with a few physical attributes (upcut, mill end, corner chamfer, etc.) combine to give you a router bit that can rout and mill steel, stainless steel, even titanium. These router bits are specifically designed for CNC machines, which is a good thing, as you can then accurately control feed rates to match the material being cut.

Monaghan Tooling Group provides the finest custom tooling solutions to the metal working industry and its customers.

To sum: Choose 2 flute endmills for efficient vertical plunging, pocketing and slotting operations. 3 and 4 fluted tools offer the promise of improved surface finishes, longer service life and increased feed-rates with peripheral milling applications.

You can also purchase the same solid carbide with AlTiN coating as a 90 degree V-spiral drill / end mill for grooving and edge-chamfering.

Amana end mills are made from their exclusive, ultra-fine micrograin carbide, and feature a 30 degree center-cutting mill end, a corner chamfer (for extra strength), up-cut design and very importantly, a AlTiN Coating.

Best End Mill Bits Router Bits | Everything CNC October 6th, 2023 3 minute read Listen to article 1x 00:00 Audio generated by DropInBlog's Blog Voice AI™ may have slight pronunciation nuances. Learn more End Mill bits are typically used for metalworking, although they can be (and often are) used on wood. Choose solid carbide to handle the high rotational speeds, specific feed rates, and cutting forces involved in metal milling. An Aluminum Titanium Nitride (AlTiN) coating provides extra wear resistance and allows for faster speed rates with less heat buildup. Amana end mills are made from their exclusive, ultra-fine micrograin carbide, and feature a 30 degree center-cutting mill end, a corner chamfer (for extra strength), up-cut design and very importantly, a AlTiN Coating. When cutting stainless steel, cast iron, or even titanium on your CNC machine, these are the bits you want. Why is it called an End Mill? Typically, end mill bits cut along the lateral sides of the bit, as opposed to plunging down into the material. You can cut slots by starting at one end of the material and cutting across, or use an end mill for profiling along the peripheral edge of the material. These End Mills Take a Plunge! With their 30 degree center-cutting mill end, and their up-cut design, Amana solid carbide CNC spiral end mills can cut metal both laterally and vertically. So go ahead, take the plunge. Suitable Materials The AlTiN coating, along with a few physical attributes (upcut, mill end, corner chamfer, etc.) combine to give you a router bit that can rout and mill steel, stainless steel, even titanium. These router bits are specifically designed for CNC machines, which is a good thing, as you can then accurately control feed rates to match the material being cut. How Many Flutes Do I Need? Two flutes provide a good balance between speed of cut and finish quality. Three or even four flutes are used for a smoother finish, and, for peripheral milling, increased speed rates. Generally, the more flutes a router bit has, the finer the finish it will produce. This is because the bit makes more cuts per revolution. This also means each flute gets less wear. However, there's a trade-off: more flutes typically mean more heat and slower material removal because the channels for chip evacuation are narrower. So, in plunge applications, 2 flutes are better. Fewer flutes typically allow for faster material removal because there's more space for the chips to evacuate. However, the finish might be rougher compared to bits with more flutes. To sum: Choose 2 flute endmills for efficient vertical plunging, pocketing and slotting operations. 3 and 4 fluted tools offer the promise of improved surface finishes, longer service life and increased feed-rates with peripheral milling applications. Chamfered Corners for Greater Strength A typical end mill's number one major wear point will be the corner, especially when making numerous plunge cuts. By chamfering the corners by 45-degrees, Amana end mills have greater edge strength and extended tool life . Wide Range of Sizes This series comes in diameters from 1/16 to 1/2 inch, and a cutting height from 3/16 to 1 inch. (As well as common metric sizes.) Longer bits will have more vibration, so always choose the shortest bit which will do the job. Still too big? Miniature end mills are designed for micro-applications including signmaking, jewelry making, and more. Doing a lot of end milling? Get a 4-pack or an 8 piece set! You can also purchase the same solid carbide with AlTiN coating as a 90 degree V-spiral drill / end mill for grooving and edge-chamfering. (Jump to 6:15 to see the 51462 End Mill rough out this bald eagle medallion.) « Back to Articles Related Articles Tips for Working With Aluminum on Your CNC Router Table 7 minute read February 6th, 2024 Best Router Bits for Trimming Laminate 3 minute read October 10th, 2023 Amana Tool Miniature Router Bits 3 minute read September 29th, 2023

The Company is widely recognized as a leading manufacturer of smart transportation solutions, obtained with heavy investments in R&D and with the achievement of unique patented solutions and production processes. Today the company has three main production sites strategically located around the world.

Product Catalog · Part Cross Reference · Products. Product Categories; Tooling Components. Tooling Components; Clamping Kits. Featured Clamping Kits.

0086-813-8127573

0086-813-8127573