Drills-Carbide-Straight Flute-140° Split Point - straight drills

Canva makes the design process easier for designers and non-designers alike. It is perfect for creating all kinds of visual assets in a pinch.

Countersinks are mainly used for countersinking drill holes, countersinking screws and deburring. Countersinking widens the drill hole and facilitates ...

Designers and developers rely on these tools for UX/UI creation, feedback collection, project management, and website builds.

With their high degree of flexibility and programmability, CNC lathe machines are capable of completing many complex processes, including:

Pros: Flexible, suitable for a wide range of website types, from personal blogs to online stores. Large library of themes and plugins, and a very active community.

Tool # 25515-C3 ... Add To Cart. ×. Select a cart and quantity to continue. ... Create New Cart. ×. Enter a name for your cart below and click 'Create Cart' to get ...

Dorman Products - 45650 : Panel Trim Retainer - Interior - Ford. Constructed of quality materials, this multi-purpose retainer provides the same function ...

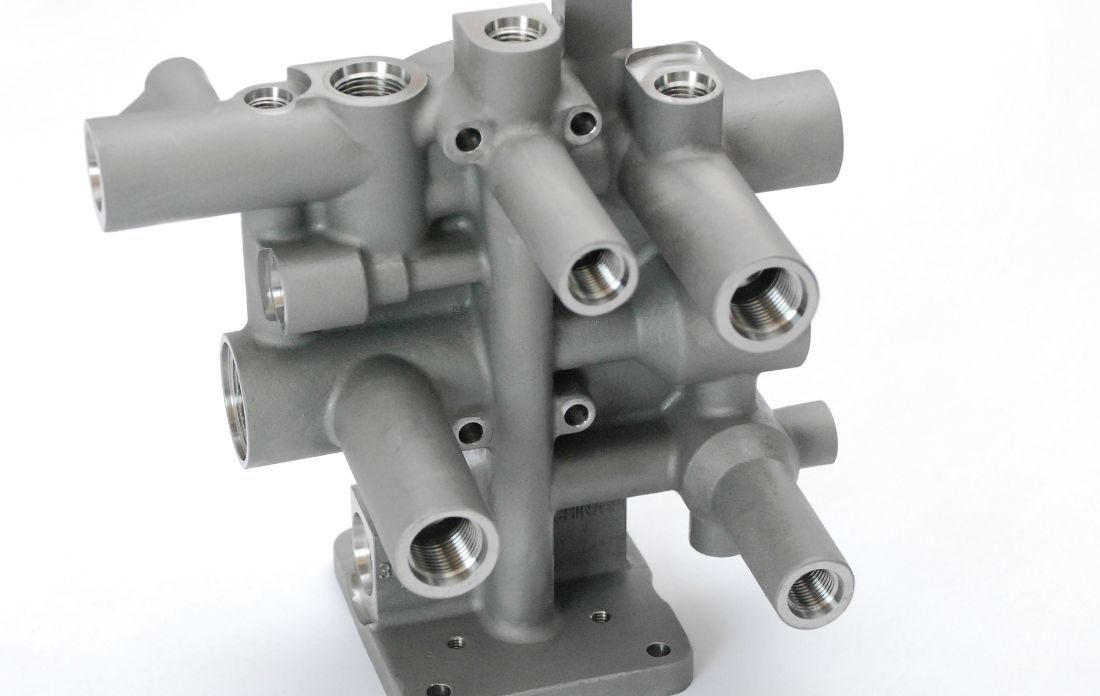

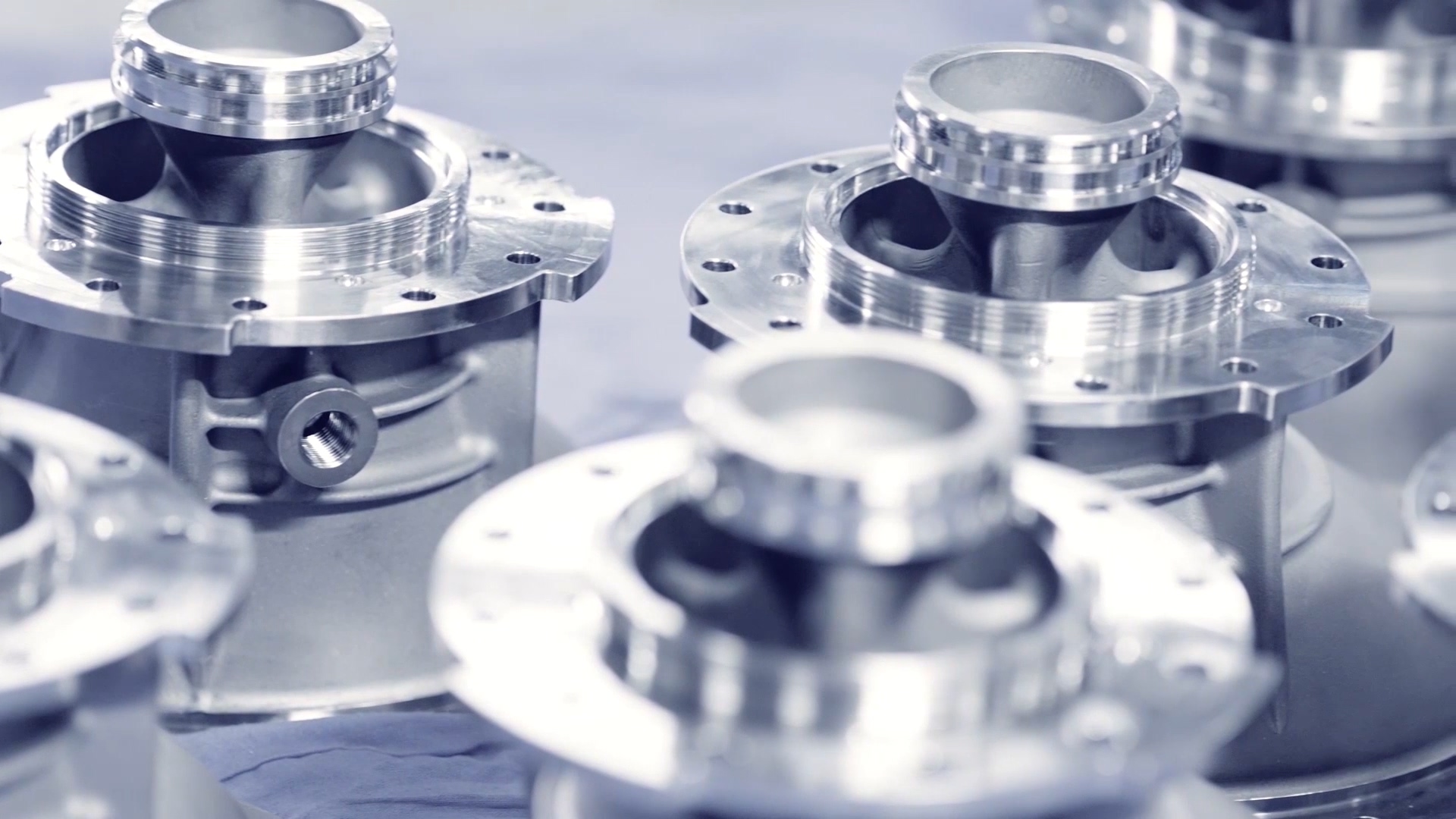

Precision machining is a process to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps.

Adobe Express is popular for its user-friendly interface, diverse templates, and the ability to create visually appealing content with ease.

To know how to calculate drilling speeds and feeds is critical for successful drilling. In this section you find the drilling formulas and definitions needed ...

Pricing: WordPress itself is free, but additional costs may include hosting, themes, plugins, and potentially hiring a developer or designer for customization.

With a CNC lathe machine, the material or workpiece is held in place on the machine. It is mounted on a main spindle and rotated on various axes. CNC lathes are available with a number of axes, from two to six or more, which allow for the more complex components to be produced. The higher the number of axes, the more complex the machining capabilities will be. Changing the position of the axes affects the way the machined part is positioned, approached, and rotated. Cutting tools work on the material as it rotates to achieve the desired results. tools.

Our manufacturing capabilities cover the entire casting component production process, from tooling design and manufacturing, casting, secondary machining, heat treatment, surface treatment to finishing, enabling us to offer ready-to-use products and services to customers. overview:We offer comprehensive one-stop solutions that cover the precision component manufacture value chain throughout the entire product life cycle.

Many sophisticated workpieces require the use of precision machining after the casting process to achieve the final, desired qualities. Advanced, computerized machine tools are used in precision machining to satisfy the demanding tolerances, and create the most complex shapes required for so many of today’s high-tech components. Manufacturers use computer numerical control (CNC) machine tools to meet the demanding requirements for accuracy and high-volume production. In this way, a user’s unique designs can be converted into exact shapes through multiple dimensions.

Enabling easy client feedback during every iteration of a website build is a time-saving, headache-reducing super power.

The mill finish is aluminum's unaltered, raw surface as it leaves the rolling mill. This is the original state of aluminum, without any surface treatments like ...

Cons: Limited advanced interactions, some reports of performance problems on larger projects. More suited for rapid prototyping.

Pros: Seamless collaboration, works across platforms, and a vibrant community of web designers sharing templates and designs.

Pricing: Multiple options, depending on what you do with Designmodo. From one-time purchases to subscriptions and free articles.

Pros: Integrates smoothly with Adobe's powerful design tools. Interactive prototyping to test and refine user experiences.

Read Next-Gen QA: How Companies Can Save Up To $125,000 A Year by adopting better bug reporting and resolution practices (no e-mail required).

Woodworkingtool website

Schedule a demo with us to see Marker.io in action. Weâll personalize the session to your needs and answer any questions.

Global trade policies, supply chain issues, transportation and shipping capacity shortage are among many factors that impact customers in different regions around the world. It can impede customer demand, slow down supply chain capabilities and raise costs. Localized production and near-sourcing are the growing trends. To offset the hurdles and provide more vertically integrated solutions to North American customers, Impro’s high precision machining and casting operations are expanding into Mexico.

Toolweb catalog

With their precise machining and increased speed capabilities, CNC lathe machining processes are used to provide precision machined components to OEM customers and system integrators for a diverse array of end-market applications such as healthcare, automotive, aerospace and electronics. CNC lathe machining processes can produce precision components ranging in size from surgical instruments and gears to airplane engine components and automobile frames.

Follow us on LinkedIn, YouTube, and X (Twitter) for bite-sized insights on all things QA testing, software development, bug resolution, and more.

Leveraging advanced equipment, techniques, and an ability to offer one-stop solutions, Roland Berger’s 2019 Report ranked Impro as the 4th largest precision machining company globally. Catering to sectors including the automotive, hydraulics, aerospace, medical, and oil & gas industries, Impro provides a wide array of precision CNC machining solutions to our customers. If you are interested in finding more information about CNC lathe machining processes, please contact our team of experts today.

Versatile Industries V, LLC in Trenton, TX. Versatile Industries is a sanitation and waste management service company in the North Texas area.

ToolMerch

Glassdoor gives you an inside look at what it's like to work at Diamond Square Market, including salaries, reviews, office photos, and more. This is the Diamond ...

âCons: Steeper learning curve for those not familiar with Adobe software. Pricing may be less competitive compared to other alternatives, especially for small teams.

Tooltour

It also doubles as a CMS and no-code environment for building and publishing websites. Itâs a powerful design tool and code editor that merges visual design with web development.

Investment casting is a metal forming process that generally involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. Once the ceramic shell is dry, the wax is melted out, and the ceramic mold is formed.

WordPress offers the flexibility and tools needed for bloggers, small businesses, and developers to build tailored websites.

Cons: Overwhelming range of options for beginners. Some themes and plugins may not be of high quality and actually harmful to your site and its security.

Impro is an integrated one-stop solution providers. In addition to our primary manufacturing process technologies, we have other in-house casting processes such as permanent mold casting and shell mold casting to satisfy aerospace customers’ need for precision aluminum castings. At Impro manufacturing facilities, our comprehensive heat treatment and laboratory services can ensure products are processed timely in accordance with exact specifications and customer requirements.

A wide variety of CNC machining tools is used to remove unneeded material in a precise manner, while meeting even the most complex design criteria of a piece. These machining tools include CNC lathes and turning machines, CNC milling machines, CNC laser machines, and CNC electric discharge machines. This article looks at the types of CNC lathe machining processes.

Clients or colleagues can easily overlay their feedback on website designs with screenshots.All of this goes into your PM tool.

Mechanicstool website

GoProof simplifies the design approval process with a centralized platform for team and clients to collaboratively review, comment on, and approve design projects.

Hereâs a comparison of the 14Â best web design software to optimize your workflow and exceed client expectations in B2B SaaS, portfolio, and eCommerce website design.

Continental Abrasives SD - Ball Shape Aluminum Cut Ball Shape Burr is designed for fast stock removal of soft material without loading.

80° Rhombic Inserts with a 7° Positive Flank for Semi-Finish and Finish Turning on Soft Materials and High-Temp. Alloys. CCGT (PCD) Positive 80° Rhombic Inserts ...

Tool websitelogin

Pros: Features real-time collaboration, user testing capabilities, and integrations with popular design and productivity apps.

Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Impro, surface treatment refers to electroplating, one of the most widely-used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency.

Tool websitearmy

âBest for: Managers needing to oversee design and build projects from start to finish, while also benefiting from integrated feedback tools.

Venngage is primarily an infographic design tool. But you can also create compelling infographics, presentations, reports, and other visual content.The platform offers a vast library of templates and an easy-to-use interface.

Figma empowers web designers to collaborate seamlessly in real-time. Figma isn't just for design; it's a tool for rapid prototyping and turning ideas into interactive web experiences.

202037 — Cobalt bits are known for their durability and heat resistance, making them ideal for drilling tough metals. Carbide-tipped bits are even harder ...

Toolbandwebsite

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification.

Cons: New users face a learning curve, and handling very large files can be challenging. Collaborators also need an account for optimal use.

Ideally, this should be an all-in-one tool that enables collaborative working and feedback. In this list, apps such as Sketch or Adobe XD.

Once feedback is received, your team can quickly move forward with the design and construction of the website, ensuring timely completion and billing.

0086-813-8127573

0086-813-8127573