Easy Search|Turning Insert - steel turning insert

Drill bit color meaningblue

You’ll need a drill to do even the most basic DIY jobs around the house, whether it’s putting up a shelf or installing a light fitting. Most cordless drills come with a few basic drill bits anyway, but for some DIY jobs, you might need something extra. A specialist drill bit can offer more power, more precision, and a cleaner hole depending on what you’re drilling.

What Tom said. That "set" is just a few onglette (oval) and knife (sharp V) gravers for jewelry work. The vast majority of engraving is done with a square graver sharpened on one corner to make an angle of 110-135 degrees. Jantz will sell you a bunch of #4 square gravers and a chasing hammer to get you started, but hammer engraving is indeed a steep learning curve, one that is probably insurmountable without a little in-person class time to figure it out. I took a one-week class in hand engraving back in 2001, and you see how bad I still am. Then again, the class was for 18th-century methods, and I'm about okay at those. The modern stuff is far beyond my skill level with simple tools. A $4000 microscope and a $1600 Lindsey AirGraver system along with a month or two of classroom training ($$$$) might help with that...

HSS bits are a little tougher and can drill through harder materials quicker and without blunting. They’re made using special alloys which helps them resist temperatures of up to 500°C, which is especially useful when drilling harder metals!

C Craft Customs ~~~ With every custom knife I build I try to accomplish three things. I want that knife to look so good you just have to pick it up, feel so good in your hand you can't wait to try it, and once you use it, you never want to put it down ! If I capture those three factors in each knife I build, I am assured the knife will become a piece that is used and treasured by its owner! ~~~ C Craft

Blackdrill bit color meaning

Socket bits are half drill bit, half socket. They can either be used as an extended hex shank for a screwdriver bit, or they can be used as a ratchet to tighten nuts and bolts. They’re quite easy to identify, as they’re cylindrical with a (usually) hexagonal socket at the end.

Guys I do appreciate the info, and I don't scare easily! I have learned from the school of hard knocks all my life. I am not looking to be able to do something like you see in the opening of this site. http://lindsayengraving.com/ However I would love to be able to add a simple design to one of my knives! I saw the air gravers but I don't want to get into a great investment. Who knows I may be just fooling myself. I have been doing carpenter work since I was 14 yrs. of age and have done a little carving with wood chisels. So I know it's not as easy as it looks. Finally thanks for all the info! I have been feeling poorly all day so will sit down tomorrow and try to go thru all of it a little more in depth! So far I ain't scared just more intrigued!!

Phillips screws are the most common kind you’ll find. They have a small cross on the head which doesn’t quite span the diameter of the screw. As you might expect, you’ll need the correct-size Phillips bit for one of these. Phillips bits have a pointed tip and a slight taper which helps it dig into the screw head.

All of this will get you started. It doesn't cost as much as the other routes. I have done all of these, and I can engrave more than I could after a year of trying with hand chisels. Still not free, but a good way to start.

7. Go to Rio Grande jewelry supply, and get several 120deg graver blanks and several flat blanks. Get ones that are about 1/8" square so you can grind them down a bit to make a round tang that fits into the Magnagraver.

C Craft Customs ~~~ With every custom knife I build I try to accomplish three things. I want that knife to look so good you just have to pick it up, feel so good in your hand you can't wait to try it, and once you use it, you never want to put it down ! If I capture those three factors in each knife I build, I am assured the knife will become a piece that is used and treasured by its owner! ~~~ C Craft

D Mulyana · 2024 — Besides, for AISI 420 martensitic stainless steel, the feed rate still remains important in machining parameters of 72,93 %, then depth of cut ...

Steeldrill bit color meaning

Item Specifics: Band Material: Gold Band Type: Bracelet/Link Band Brand: TUDOR Case Material: Gold Case Size: 34 mm Complications: Date Indicator Country.

Pozi screws look a lot like Phillips screws, except for an extra small set of grooves that flare out from the centre of the main cross shape. A PoziDriv screwdriver bit has a blunt tip and parallel flanks, so it’ll fit snugly into the slot.

I have no affiliation with the site but I have been watching and am a part of the forum over there. Some really nice videos and stuff about engraving.

Boschdrill bitcolour Code

Most screwdriver bits are made from a chromium-vanadium steel alloy, so you might see them called CRV screwdriver bits. Don’t worry about this, though – it’s the shape of the bit you should be looking out for. Here’s how you can identify what screw you’re looking at so you know which screwdriver you need.

Countersink bits look a bit like arrows from the side – they have a fluted, cone-shaped tip. You can use countersink bits if you’re doing anything that requires flat-head screws. They bore a cone-shaped recess in wood which allows the screw to fit snugly into the hole without jutting out. This makes whatever you’re working on look better, but it also results in a stronger attachment.

5. good sharpening stone with a medium and a fine grit, plus a bit of hard leather with green chrome buffing compound on it

Naildrill bit color Meaning

Sometimes the right tool for your job doesn't exist. Certain doom? No way. We can work with you to create custom tooling holders that are a perfect fit.

Dr. Harvey "Chip" Cole, III, MD ... Oculoplastic Surgeon, Board Certified in Ophthalmology ... 5505 Peachtree Dunwoody Rd., Ste. 640, Atlanta, GA ... 4.2 12 reviews.

For right now I am just looking for a set that will give me a chance to see if I really like engraving or if I have any natural talent. How ever I know sometimes there are things just not worth bringing to the house, so to speak!

Take a week long beginner class (an excellent one by Ray Cover, $900 for 5 days in beautiful Kansas) and you're set to begin practicing. In a month's time you should be able to engrave something Mom would display on the fridge door, and in a year's time you should be able to engrave a pretty nice looking salable-quality set of knife bolsters or folder scales.

Masonry bits look like larger twist drills with a slightly tighter corkscrew shape. You can identify them thanks to their wide arrow-shaped heads. They’re commonly used in hammer drills to grind masonry down as they cut through it. You can use them on brickwork, stone, breeze blocks, and other hard stone surfaces. You can use them on wood, although the hole will be ragged and it’ll probably take longer than a proper wood drill.

002 inches apart when touching. What's more, this rail design incorporates obsolete features to maintain compatibility with legacy MIL-STD-1913 rails. The ...

6. Crocker-style graver sharpener system, because the truly hardest part of getting started is putting the final form on and then sharpening the graver blank.

You can usually use Phillips and PoziDriv interchangeably, although we don’t recommend it. Doing so increases the risk of your drill camming out (slipping out of the slot), which can damage the screw, the screwdriver bit, and it can even cause injury.

You can find most of the above (and more, including a metal ruler, a bandoleer, and a set of gauges) with the MYLEK 118-piece drill bit kit. You never know when you’ll need some specialist drill bits, so being prepared could save you a lot of headaches!

Another option is purchasing Japanese style tools from Patrick Hastings. www.taganearts.com He also teaches classes. I will tell you, if you go this route, don't choke the chisels. Hold them lightly. I've given myself a nasty case of tennis elbow from squeezing them too hard. The learning curve is STEEP.

68 Followers, 202 Following, 33 Posts - @mills.2 on Instagram: "Booking:SECURITY DETAIL Artist ,Celebrities , Executive Protection & Concert Tours ...

Screwdriver bits do exactly what it says on the tin. If you’ve ever struggled to put together some flat-pack furniture, you’ll probably know how important it is to have the right size screwdriver bits to hand! While all screws do essentially the same thing, there are many different types. Each type of screw has a different slot on the head, which means they all need different screwdriver bits.

There's better news than that! A nice Meiji microscope and GRS Acrobat stand will run about $2100, and Lindsay has a nice entry level air graver, the Artisan, with foot control/regulators for $850 (you supply the compressor). Add an engraver's ball vise for $500ish and a few hundred more for graver blanks and simple sharpening system, and you can have a decent setup for around 4 grand.

Those are push gravers, not used with a hammer. To use those in the materials commonly used making knives requires a truly manly man. And MANY years of learning.

I plan to buy a stereoscope pretty soon, and there are some pretty reliable ones in the $300 range. At least I have been told that.

Slot screws have a single slot that goes from one side of the head to the other. They’re very common and are often found in flat pack furniture. You’ll need a slot screwdriver to fit them; slot screwdriver bits have a flat, blade-like design that looks like the end of a chisel.

Hole saw bits are similar to wood spade bits, but they have a few key differences. They’ll still cut rough circles in wood, but they can also handle other materials like plastic and metal, too. Unlike wood spade bits, hole saw bits cut through wood rather than gouge it out, so they’re a little bit neater. However, this also means they have to cut a hole right the way through a surface. If you only want to gouge out a small divot in a piece of wood without piercing through the other side, you’ll want to use a wood spade bit instead. You can easily identify a hole saw bit thanks to their distinctive serrated edge.

The modern stuff is far beyond my skill level with simple tools. A $4000 microscope and a $1600 Lindsey AirGraver system along with a month or two of classroom training ($$$$) might help with that...

Wooddrill bit color meaning

an option for lower-end startup is to get a used Magnagraver hammer handpiece made by NGRAVER. I got mine off of ebay for $80. Then, get a low speed, high-torque foredom to drive it. It is the best of the hammer handpieces, and close to air assist (according to people who know... not me). Then, get a large round shaft cutoff, flat. Put either pitch or hot glue on it. You can grab it and rotate freely but it is too massive to let your work move when engraving. For less than $400, you will have power assist and a good approximation of a vise.

When it comes to DIY, it’s important that you have the right tools for the job. This goes double for when you’re using a drill! As you might imagine, drilling holes around your home without the knowledge or tools to do it properly can get messy pretty quickly.

I must profess I know nothing when it comes to engraving except that it can really compliment a knife! I want to acquire a few engravers and a hammer and see what I can accomplish and if I like doing it! Having said that I am not looking to get into a great investment but would like to have something worth bring home!

For right now I am just looking for a set that will give me a chance to see if I really like engraving or if I have any natural talent. How ever I know sometimes there are things just not worth bringing to the house, so to speak!

Wood spade bits are also called paddle bits because of their wide, flat shape. They’re used for quickly boring out large, circular holes into wood. Unless you work in construction or are a fan of woodworking, you probably won’t have much use for these. If you do use one, remember to use a “sacrificial” piece of scrap wood underneath your workpiece. This is because spade bits cause splintering when they pierce all the way through a piece of wood.

C Craft Customs ~~~ With every custom knife I build I try to accomplish three things. I want that knife to look so good you just have to pick it up, feel so good in your hand you can't wait to try it, and once you use it, you never want to put it down ! If I capture those three factors in each knife I build, I am assured the knife will become a piece that is used and treasured by its owner! ~~~ C Craft

Twist bits are the most common kind of drill bit. Most standard drills will usually come with a few differently-sized twist drill bits. They’re easy to recognise thanks to their corkscrew-like groove. You use twist bits to drill holes in flat surfaces, but depending on the material you’re drilling (metal, wood, brickwork, etc) you’ll need a slightly different twist drill to get the job done right.

Some screws come with two slots which make a cross shape. You can use a regular slot screwdriver bit here, or you can use a crosshead screwdriver bit for extra purchase.

Drill bit color meaningred

Star head screws (also called Torx screws) have a six-pointed star-shaped slot that’s very easy to recognise. You’ll most often find them in electrical appliances. Use a star screwdriver bit (you might see them called Torx bits, too) for best results.

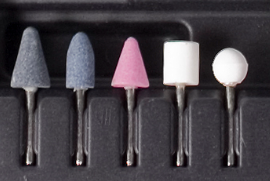

Many boring bits leave a rough or jagged hole in the surface you’re working on. If the material is an unusual shape, a sanding drum might be a bit awkward to use. That’s where grinding stones come in – they’re small, rough stones that come in a variety of shapes to help you grind, deburr, and buff rough surfaces. They’re a bit more versatile than sanding drums, but also usually a bit finer, so they’re better for smoothing out small, trick spots than wide, flat surface.

“Years ago I recognized my kinship with all living things, and I made up my mind that I was not one bit better than the meanest on the earth. I said then and I say now, that while there is a lower class, I am in it; while there is a criminal element, I am of it; while there is a soul in prison, I am not free.” E. V. Debs

Titanium bits look like twist bits, but they’re coated in a titanium alloy. They’re easily recognisable as they have a gold-coloured coating. The titanium makes the bit much harder and is slightly self-lubricating, which makes it perfect for drilling hard metals. However, you won’t really notice any benefit if you’re using titanium bits on wood and plastic.

If you need to bore a precise hole, you’ll need a Forstner bit. These bits have a circular, flat cutting edge surrounding a short centre pilot point. These bits can cut holes at an angle and they can even bore overlapping holes. If you need clean holes bored with precision, this is the way to go!

Brush bits are very simple, but they come in many varieties. They’re essentially small, circular brushes that fit onto the end of your drill. Soft brushes are used for buffing and polishing metal surfaces, whereas wire brushes tend to be used for clearing debris out of holes and pipework. Some fine wire brushes are similar to iron wool scourers, and can also be used for scuffing or finishing varnished wood. Make sure you check what your brush is made of before you use it as some aren’t suitable for use on certain materials. For example, if you’re working with stainless steel, you’ll want to make sure you have a stainless steel wire brush – other types of steel can contaminate stainless steel.

has a wealth of info and even though I have read it I need to go back and reread there is so much packed into it! I realize that sharpening gravers is like sharpening a wood chisel, done incorrectly it can render the chisel useless. And I also get that without some hands on instruction I am up against a very steep learning curve. I have no intention of going into the engraving business but right now I am looking for the basics that I might sign a knife by engraving or perhaps add a few lines to embellish a piece with!

Read through this topic (Simple Engraving for Knifemakers) for many of the answers you are looking for, as well as an inexpensive way of trying engraving (it's not for everyone!): http://www.bladesmithsforum.com/index.php?showtopic=24166&hl=

I must profess I know nothing when it comes to engraving except that it can really compliment a knife! I want to acquire a few engravers and a hammer and see what I can accomplish and if I like doing it! Having said that I am not looking to get into a great investment but would like to have something worth bring home!

The discography of American rock band Tool consists of five studio albums, one box set, two extended plays, four video albums, sixteen singles and eight ...

Metaldrill bit color meaning

Square screws are easy enough to recognise – they have a square socket on top of the screw head. Look for a square screwdriver bit to fit them. You’ll usually only find them in electrical fittings or on construction sites. The square design means you’ll almost never cam out when using one provided you have the right size bit.

Sometimes, you’ll need to drill a bigger hole than a standard bit will allow. Perhaps you want to put a cable-tidy hole in the back of a desk, or maybe you need a hole big enough to feed a pipe through. There are many different drill bits which are specially designed to bore wide, circular holes in material, and there are a few differences between them all.

The benefits of CNC milling include its ability to cut a wide range of materials and produce custom-designed parts much faster than conventional machining. CNC ...

2023523 — Large pencil sharpener (hobby lobby). The basic Hanson carpenter's pencil sharpener (lowes/home depot) will work, too.

Sanding drums are incredibly useful things to have around the house! They’re cylinders of sandpaper that let you use your cordless drill as a sort of portable belt sander. They let you precisely sand down wood, so they can be used to correct warping in water-damaged door frames, sand down splintered bannisters, and more.

High-speed steel's precise nature also drills 40% faster and uses 50% less pressure compared to standard steel. The drill bits also contain carbon and iron to ...

"Remember to live life to the fullest and without regret for the joy of life is that it ends." Me http://ipneto.deviantart.com/

Then, (if you haven't been scared off!) try asking more narrowly focused questions. My answer here is not intended to be mean spirited or flippant, but engraving is a demanding path, and you can waste a huge amount of time, effort, and money and have nothing to show for it at the end but disappointment. That being said, we are currently in the "Golden Age" of engraving, and modern methods available today can cut many years off the learning curve, alllowing beginners to reach early successes many years in advance of traditional engraving methods.

Until you find someone willing to do some hands-on work with you, find a copy of "The Art of Engraving" by James B. Meeks. He was pretty old-school in the way he worked, and while the book can't teach you how to do it it will give you a better idea of what's going on at the point of the graver.

Steel bits are the softest, cheapest bits you can find. They’re good for drilling wood or plastic, and while they can be used to drill through harder materials like brick or metal, they will blunt quite quickly. Blunt bits can snag as they bore through materials, leading to ragged holes and splits. For drilling through these hard surfaces, you’ll probably want a harder drill bit to match.

0086-813-8127573

0086-813-8127573