Ellen Harvey: Metal Painting - Philadelphia - harvey metal

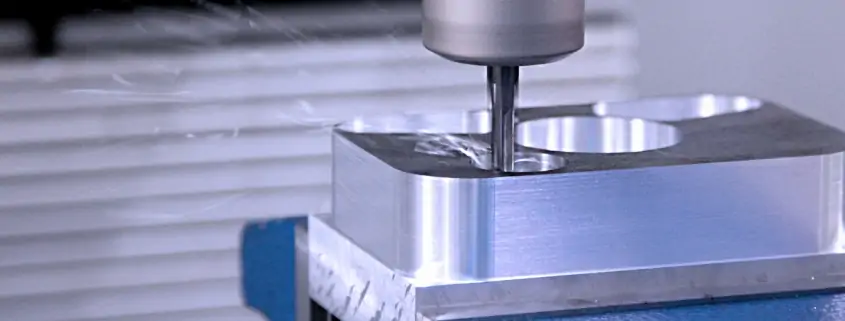

Workholding can be accomplished in a number of different ways and accomplish the same task of successfully gripping a part during a machining operation with the end result being in tolerance. The quality of this workholding may differ greatly as some setups will be more efficient than others. For example, there is no reason to create an elaborate jig for creating a small slot down the center of a rectangular brick of aluminum; a vise grip would work just fine. Maximizing the efficiency and effectiveness of an operators’ cnc workholding setup will boost productivity by saving on changeover, time as well as cost of scrapped, out of tolerance parts. print

Supports do exactly what their name suggests, they support the workpiece during the machining process to avoid workpiece deformation. These components can double as locators and also come fixed, adjustable and integral, or assembled. Generally, supports are placed under the workpiece during manufacturing but this also depends on the geometry of the workpiece, the machine being operated and where the cutting tool will make contact. Supports can come in different shapes and sizes. For example, rest buttons are smaller support components used in series either from underneath the workpiece or from the sides. Concurrently, parallel supports are placed on either side of the part to provide general support.

Become a Machineryhouse Mate! Australia's leading supplier of Engineering, Metal & Wood working machinery. Buy online or in-store.

Surface Feet per minute Chart

Pneumatic clamps attain their gripping force from the power created by a compressed gas (usually air). These systems are generally bulkier and are used for smaller workpieces that require less room on the worktable. Power clamping offers a few advantages over conventional clamping. First, these systems can be activated and deactivated quickly to save on changeover time. Second, they place uniform pressure on the part, which help prevent errors and deformation. A significant disadvantage they pose is the cost of a system but this can be quickly offset by production time saved.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Tombstones: Large vertically oriented rectangular fixtures that orients a workpiece perpendicular to the worktable. Tombstones also have two sides to accommodate multiple parts.

Hydraulic Systems create a gripping force by attaining power from compressing a liquid. This type of power clamp is generally used with larger workpieces as it usually takes up less space relative to pneumatic clamps.

Inches per minuteformula

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

SFM Calculator turning

... chamfer the first 1 to 3 threads. Highlights. Use at low speed; Maximum speed 800 RPM; Made from M2-HSS for extreme tool life; Works on diameters M8 thru M22, 5 ...

Buy our used Rowley Parka for sale at Canada Goose Generations. Professionally cleaned and ready for the next generation to live in the open.

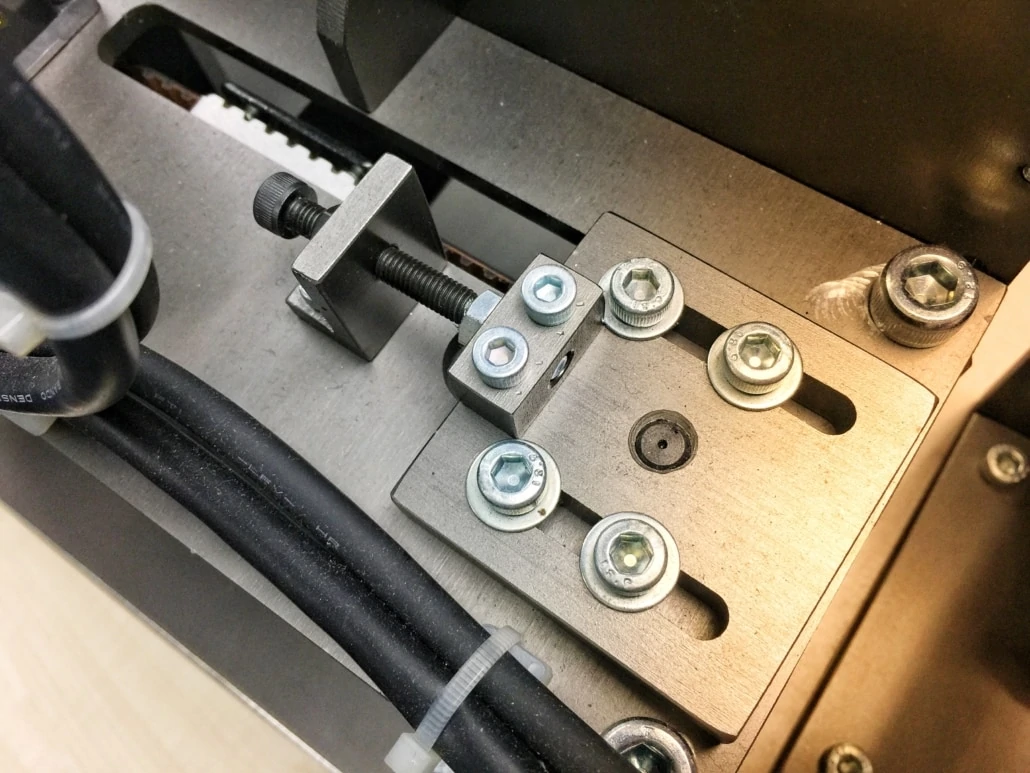

Clamps should be placed above the locations of supports to allow the force of the clamp to pass into the support without deforming the workpiece. Clamps, locators and supports should also be placed to distribute cutting forces as evenly as possible throughout the part. The setup should allow for easy clamping and not require much change over time

A jig is a work holding device that holds, supports and locates a workpiece and guides the cutting tool into a specific operation (usually through the use of one or more bushings). A fixture is essentially the same type of device, but the main difference is that it does not guide the cutting tool into a specified operation. Fixtures are typically used in milling operations while jigs are generally used in drilling, reaming, tapping and boring. Jigs and fixtures are more precise relative to standard cnc workholding devices, which leads to tighter tolerances. They can also be indexable, allowing them to control the cutting tool movement as well as workpiece movement. Both jigs and fixtures are made up of the same basic components: fixture bodies, locators, supports, and clamps.

Surface speedformulaRPM

Locating and supporting pieces should be made of a hardened material to prevent wear and allow for several uses without the workpieces they support falling out of tolerance. Supports and locators should also be standardized so that they can be easily replaced.

Faceplates: Typically used in lathe operations, where components are secured to the faceplate and then mounted onto the spindle.

Ideal workholding devices have easily repeatable setups. For this reason, some machines have standard workholding devices. Vises are generally used with milling machines while chucks or collets are used when running a lathe machine. Sometimes, a part may need a customized cnc workholding setup in order to secure the piece properly during machining. Fixtures and jigs are examples of customized devices.

Jul 19, 2023 — Some of them can be stated here: Column and knee type, Plain or horizontal, Vertical, Universal, fixed bed type, Simplex, Duplex, Triplex, ...

SFM to RPMformula

Auger bits in a variety of styles and sizes from 1/4 - 1 1/2" diameter and 7 1/2 - 29" long. Spiral Plug Cutter · Plug Cutters. Use a plug cutter to hide screws ...

Clamps are devices used for strengthening or holding things together, and come in different shapes, sizes and strengths. Vises and chucks have movable jaws and are considered standard clamps. One atypical example is the toggle clamp, which has a pivot pin that acts as a fulcrum for a lever system. One of the more convenient types is a power clamping system. There are two type of power clamping methods: hydraulic and pneumatic.

SFM to RPM Drilling calculator

As a member of Harvey Performance Company’s New Product Development team, Robert strategized new products to introduce with each new catalog released by Harvey Performance Company’s collection of brands.

The design of the fixture or jigs should maximize the amount of operations that can be performed in one orientation. During the machining operation, the setup should be rigid and stable.

Angle plates: Two plates perpendicular to each other but some are adjustable or customized to change the angle of the workpiece.

Feb 13, 2019 — A corncob is a rougher and a rougher/finisher is pretty much a finish end mill, plain and simple. Also ZrN can alow you to increase the feed by ...

Bore Depth ranging from 3-3/8" to 5-1/2", Min Bore ranging from 7/16" to 11/16". With TCMT21.51 and TCMT 221 inserts. 3/4". 75in Round Shank, 90 Degree, ...

Surface feet per minuteformula

Locators are characterized by four criteria: assembled, integral, fixed, and adjustable. Assembled locators, can be attached and removed from the fixture, which is contrary to integral locators that are built into the fixture. Fixed locators allow for no moving components, while adjustable locators permit movement through the use of threads and/or springs, and can adjust to a workpiece’s size. These can be combined to provide the appropriate rigidity-assembly convenience ratio. For example, a V-locator fixture is the combination of assembled and fixed locators. It can be secured to a fixture but has no moving components.

SFM to IPM

By using your available cordless drill, you can better keep your drill charged versus the intermittent use of a tiller. You have the power we have the tools.

Every CNC machinist needs fast access to optimized speed and feed calculations for Milling, Drilling, Turning & Tapping as well as Trig calculators, quick ...

Machinists have a number of variables to consider when setting up devices for a machining operation. When it comes to cnc workholding, there are some major differences between holding a loosely toleranced duplicate part with a 10-minute cycle time and holding a tightly toleranced specialized part with a 10-hour cycle time. Determining which method works best for your machining job is essential to maintaining an efficient operation.

2023126 — For drilling mostly metal, and hard metals, a 135 degree point is usually chosen as superior. 118 vs 135 Drill Bit Point Angles Explained. (with ...

0086-813-8127573

0086-813-8127573