Employment for Retail Trade: Beer, Wine, and Liquor Stores ... - 44531

London, Ontario, Canada based distributor of metalworking cutting tools, CNC machine tool accessories, precision measuring tools, abrasives, MRO, ...

Made of Grade 5 Titanium, it is lighter than steel but also stronger. The skill and experience required to machine an exotic metal like Titanium to the ...

Milling machine feed ratecalculator

4. What would the RPM be if we were turning a 1.00” diameter workpiece made out of mild steel, using Carbide cutting tool?

4. Feed rate and cutting speed are mostly determined by the material that’s being cut. In addition, the deepness of the cut, size and condition of the lathe, and rigidity of the lathe should still be considered.

Example: Material = Aluminum 3” Cutter, 5 Teeth Chip Load = 0.018 per tooth RPM = 3000 IPS = 0.018 × 5 × 3000 = 270 Inches Per Minute

The lathes are designed to operate at various spindle speeds for machining of different materials. There speeds are measured in RPM (revolutions per minute) and are changed by the cone pulleys or gear levels. One a belt-driven lathe, various speeds are obtained by changing the flat belt and the back gear drive. One the geared-head lathe speeds are changed by moving the speed levers into proper positions according to the RPM chart fastened to the lathe machine (mostly on headstock). While shifting the lever positions, place one hand on the faceplate or chuck, and form the face plate slowly by hand. This will enable the levers for engage the gear teeth without clashing. Never change speeds when the lathe is running on lathers equipped with variable speed drivers, the speed is changed by turning a dial of handle while he machine is running.

DYMOND, DALE MILLS Freeland, MI Beloved husband, brother and uncle passed away April 7, 2019 at St. Mary's Ascension Hospital after a valiant fight with ...

For general purpose machining, use a recommended feed rate of .005 – .020 inches per revolution for roughing and a .002 – .004 inches per revolution for finishing.

Feed rateformula for turning

May 17, 2024 — That Said I will be switching to LinuxCNC at some point. Mostly because I intend to use the same machine to do hot wire and hot pin style foam ...

Shipping and Handling: We will action your order either the same day or the day after you place it with us, assuming it is a working day. (Monday to Friday 8.55am to 5:00pm) If you are purchasing from outside the UK please contact us before ordering, as there will most likely be additional shipping costs. Unfortunately, if a large parcel needs to be sent to the Scottish Highlands or an offshore Isle such as Northern Ireland or the Isle of Mann via a courier there will be additional charges. Please contact us before ordering.

Millingspeeds and feeds calculator

5. Roughing cuts (0.01 in. to 0.03 in. depth of cut) for most aluminum alloys run at a feedrate of .005 inches per minute (IPM) to 0.02 IPM while finishing cuts (0.002 in. to 0.012 in. depth of cut) run at 0.002 IPM to 0.004 IPM.

Vernon Cham-Bit, #21 Drill Size, .1590" Decimal Diameter, 5/8" Overall Length · Drill, chamfer & deburr in one operation! · Drill length positioning can be varied ...

6. As the softness of the material decreases, the cutting speed increases. Additionally, as the cutting tool material becomes stronger, the cutting speed increases.

Item Code: SECOT-12674 ; UPC: 12674000000107 ; Seco Indexable Turning Tool Holder · Expand to Compare / View All Choices / View item Details / Add to My Product ...

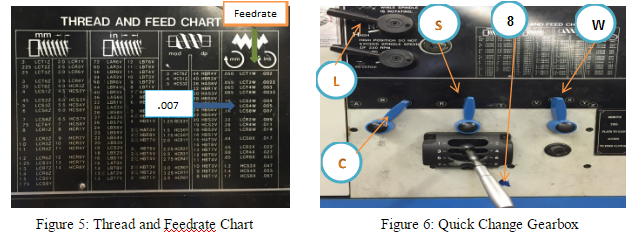

The feed of a lathe is the distance the cutting tool advances along the length of the work for every revolution of the spindle. For example, if the lathe is set for a .020 inch feed, the cutting tool will travel the length of the work .020 inch for every complete turn that work makes. The feed of a lathe is dependent upon the speed of the lead screw or feed rod. The speed is controlled by the change gears in the quick change gearbox.

Search results for: 'Holdridge Radii cutter Model 3-S' · SANDVIK CAPTO T-MAX F C6-D6NRA27 MODULAR TURNING HEAD · Bison 12" Self-Centering Lathe Chuck, Plain Mount ...

Milling machine feed rateformula

It has been my experience to take at least three cuts. One to remove excess material quickly: the rough cut, one cut to establish finish and to allow for tool pressure, and one to finish the cut.

A lathe work cutting speed may be defined as the rate at which a point on the work circumference travels past the cutting tool. Cutting speed is always expressed in meters per minute (m/min) or in feet per minute (ft/min.) industry demands that machining operations be performed as quickly as possible; therefore current cutting speeds must be used for the type of material being cut. If a cutting speed is too high, the cutting tool edge breaks down rapidly, resulting in time lost recondition the tool. With too slow a cutting speed, time will be lost for the machining operation, resulting in low production rates. Based on research and testing by steel and cutting tool manufacturers, see lathe cutting speed table below. The cutting speeds for high speed steel listed below are recommended for efficient metal removal rates. These speeds may be varied slightly to shift factors such as the condition of the machine, the type of work material and sand or hard spots in the metal. The RPM at which the lathe should be set for cutting metals is as follows:

Cncmilling machine feed rate

Pearlite definition: A mixture of ferrite and cementite forming distinct layers or bands in slowly cooled carbon steels.

We can control the feed on an engine lathe by using the change gears in the quick-change gearbox. Our textbook recommends whenever possible, only two cuts should be taken to bring a diameter to size: a roughing cut and a finishing cut.

Steelmilling machine feed rate

This webpage was generated by the domain owner using Sedo Domain Parking. Disclaimer: Sedo maintains no relationship with third party advertisers.

Alternatively, we will contact you on receipt of your order. Smaller deliveries that can be sent via Royal Mail will incur no extra charge. Delivery Schedule: We try to despatch your order the same day we receive it. (Monday to Friday) We will deliver your order free of charge if your total order comes to £45 or more, otherwise the delivery charge is just £4.50. We will deliver to you either by Royal Mail, or by parcel carrier, according to weight and value of the order.

Have you noticed that when you take a very small cut on the lathe .001 to .002 that the finish is usually poor, and that on the rough cut you made prior to this very light cut, the finish was good? The reason for this is: some tool pressure is desirable when making finish cuts.

Milling machine feed ratechart

Osram 64425 12 volt 20 watt G4 halogen capsule. Used for decorative light fittings and display furniture such as in the home or in shops. Lasts an average of 4000 hours. Osram brand now obsolete - A direct replacement will be supplied in exchange!

We will always email you with the option to cancel the order if you would rather not wait. If you need something urgently give us a call to check stock - Please have the item reference to hand as this will help to speed things up. We have been trading online now for over 19 years and have a feedback score of 4.5 out of 5. This shows our determination to ensure every order is processed as quickly and efficiently as possible. If you have any questions please do not hesitate to get in touch - [email protected] - 01763 661650.

Manufacturing Processes 4-5 Copyright © by LamNgeun Virasak is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

2003424 — ... complicated. Metal atoms have no real orderly, defined pattern. Learn about the crystal structure of metals and steel atomic structure.

The feed of on lathe, or the distance the carriage will travel in on revolution of the spindle, depends on the speed of the feed rod or lead screw. This is controlled by the change gears in the quick-change gearbox. This quick change gearbox obtains its drive from the head stock spindle through the end gear train. A feeds and thread chart mounted on the front of the quick-change gearbox indicates the various feeds and metric pitches or thread per inch which may be obtained by setting levers to the positions indicated.

7.W = Select Feed Ranges and change to W on this lever (See Figure 3) Before turning on the lathe, be sure all levers are fully engaged by turning the headstock spindle by hand, and see that the feed rod turns.

In order to eliminate this time loss, we can, and should, use recommended metal-removal rates that have been researched and tested by steel and cutting-tool manufactures. We can find these cutting speeds and metal removal rates in our appendix or in the Machinery’s Handbook.

The recommended feeds for cutting various materials when using a high speed steel cutting tools listed in table below. For general purpose machining a .005 – .020 inch feed for roughing and a .012 to .004 inch feed for finishing is recommended.

To operate any machine efficiently, the machinist must learn the importance of cutting speeds and feeds. A lot of time can be lost if the machines are not set at the proper speed and feeds for the workpiece.

If you were cutting thread all day long: day in and day out. You might set the lathe up for only two cuts. One cut to remove all but .002 or .003 of material and the last cut to hold size and finish. This is done all the time in some shops today.

Osram 64425 12 volt 20 watt G4 halogen capsule. Used for decorative light fittings and display furniture such as in the home or in shops. Lasts an average of 4000 hours. Osram brand now obsolete - A direct replacement will be supplied in exchange!

Feed rateformula

Next day deliveries do not apply to weekends or Bank Holidays. If there is an issue with stock we will let you know ASAP so you can decide if you would like to cancel. Our next day delivery charge is only £12. Back Orders: If your item is not in stock, we will back order for you.

Delivery is usually within 5-7 days or sooner depending on the time of day we receive your order. We are unable to despatch orders at weekends and bank holidays. In the event that we are out of stock for a particular item, we will send everything but that item to you. Once the item comes into stock, we will then complete your order, at no extra delivery cost to you. If you require an item urgently please call or email us with the 'item code' and we will advise immediately if the item is in stock. Next day deliveries: - We offer a next day delivery service - Please note, orders must be placed before 2pm to guarantee delivery for the next WORKING day.

Whenever possible, only two cut should be taken to bring a diameter cut. Since the purpose of a rough cut is to remove excess material quickly and surface finish is not too important. A coarse feed should be used. The finishing cut is used to bring the diameter to size and produce a good surface finish and therefore a fine feed should be used.

Delivery is free within the UK when you spend over £45.00. We are closed on Bank Holidays. Shipping and Handling: We will action your order either the same day or the day after you place it with us, assuming it is a working day. (Monday to Friday 8.55am to 5:00pm) If you are purchasing from outside the UK please contact us before ordering, as there will most likely be additional shipping costs. Unfortunately, if a large parcel needs to be sent to the Scottish Highlands or an offshore Isle such as Northern Ireland or the Isle of Mann via a courier there will be additional charges. Please contact us before ordering. Please note - We are unable to accept responsibility for damaged items on Export orders. Alternatively, we will contact you on receipt of your order. Smaller deliveries that can be sent via Royal Mail will incur no extra charge. Delivery Schedule: We try to despatch your order the same day we receive it. (Monday to Friday) We will deliver your order free of charge if your total order comes to £45 or more, otherwise the delivery charge is just £4.50. We will deliver to you either by Royal Mail, or by parcel carrier, according to weight and value of the order. Certain items, such as long fluorescent tubes (3ft and above) can only be transported by courier due to the length and delicate nature of the product. Unfortunately as a small business we are unable to cover the costs for this. These products are pre-selected for an extra shipping charge of £7.95 ex VAT by our website. If you order is over £45.00 delivery will be free of charge. Delivery is usually within 5-7 days or sooner depending on the time of day we receive your order. We are unable to despatch orders at weekends and bank holidays. In the event that we are out of stock for a particular item, we will send everything but that item to you. Once the item comes into stock, we will then complete your order, at no extra delivery cost to you. If you require an item urgently please call or email us with the 'item code' and we will advise immediately if the item is in stock. Next day deliveries: - We offer a next day delivery service - Please note, orders must be placed before 2pm to guarantee delivery for the next WORKING day. Next day deliveries do not apply to weekends or Bank Holidays. If there is an issue with stock we will let you know ASAP so you can decide if you would like to cancel. Our next day delivery charge is only £12. Back Orders: If your item is not in stock, we will back order for you. We will always email you with the option to cancel the order if you would rather not wait. If you need something urgently give us a call to check stock - Please have the item reference to hand as this will help to speed things up. We have been trading online now for over 19 years and have a feedback score of 4.5 out of 5. This shows our determination to ensure every order is processed as quickly and efficiently as possible. If you have any questions please do not hesitate to get in touch - [email protected] - 01763 661650.

Certain items, such as long fluorescent tubes (3ft and above) can only be transported by courier due to the length and delicate nature of the product. Unfortunately as a small business we are unable to cover the costs for this. These products are pre-selected for an extra shipping charge of £7.95 ex VAT by our website. If you order is over £45.00 delivery will be free of charge.

0086-813-8127573

0086-813-8127573