End Cutting Long Reach Pliers - end reach

Used Slack kart for sale

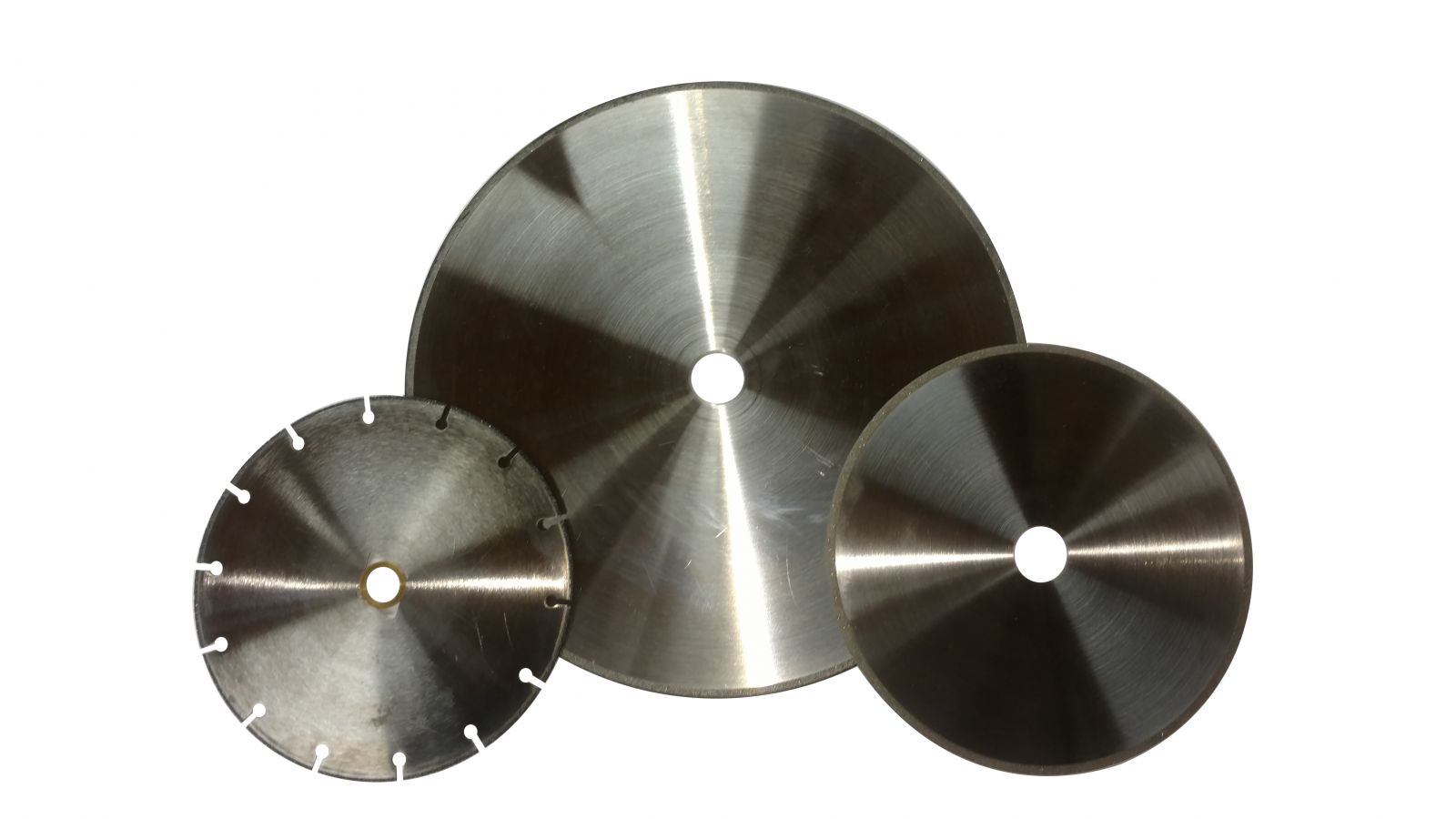

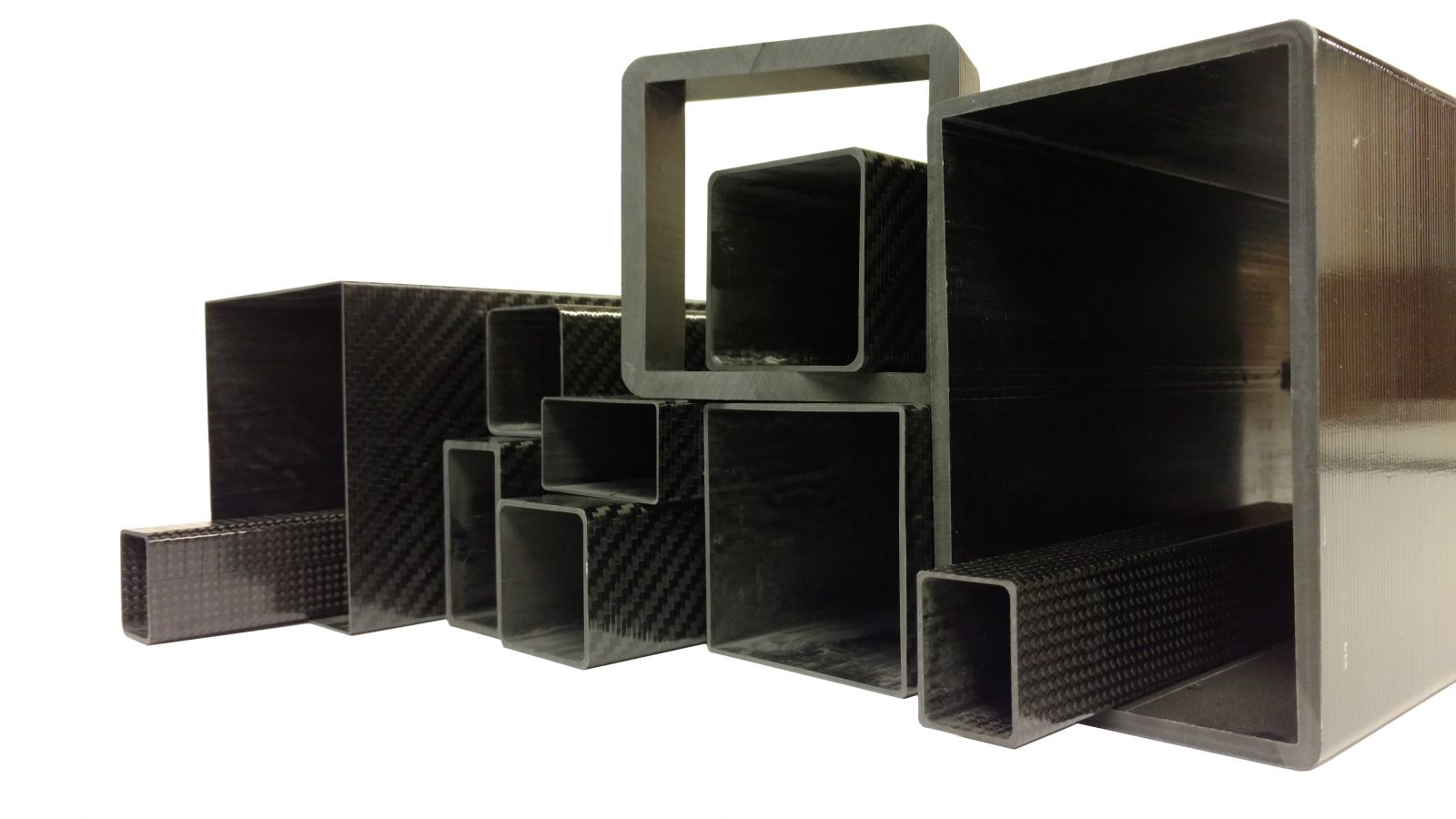

Cutting carbon fiber tubing can be difficult. If done incorrectly, the tube can be damaged beyond repair in the blink of an eye. This article will break down the steps on how to cut carbon fiber tubes.

(Bonus) Fraying:When cutting aramid or carbon/aramid hybrid tubes the cut edge is often “fuzzy”. Aramid is a difficult material to cut, it is very tough. The Fuzz is result of the aramid tearing instead of cutting.

Performance manufacturinggo karts

Delamination: Delamination often occurs when cutting unidirectional tubing. Individual filaments or tows tear away from the rest of the composite.Fix: Slow down, take your time while cutting the tube. Let the material grind away at its own pace. Do not force the blade through the tube. If you are still having issues, try using a thinner blade with finer grit.

Performance manufacturingparts

Also, take care around electronics; the conductive nature of carbon can easily fry nearby computers, laptops, and other devices. With this in mind, ensure proper precaution is taken prior to making your first cut. It may be worth covering or moving any devices in the area.

Burring: Burring occurs at the last second of cutting. This is due to lack of support/securing one, or both, ends of the tube. The carbon fiber tube begins to break away as the final filaments are cut.Fix: Secure both ends of the tube. Use a weight or clamp to ensure minimal movement throughout the cut.

Performance manufacturinggo kart parts

With a focus on precision and efficiency, the company offers a wide range of manufacturing services to meet the needs of various industries.

Overheating:Overheating is often result of intense friction. It is often occurs when cutting thicker walled carbon fiber tubes. The resin reaches its TG and begins to flow.Fix: Reduce heat. Here we have a few options. Either slow down to reduce friction or use liquid as a coolant to keep the heat down. If you are cutting multiple tubes it may save time to use a wet saw.

Performance manufacturingkart parts

Performance Manufacturing is a reputable company based in Kelowna, BC, specializing in the production of high-quality industrial components.

Overheating:Overheating is often result of intense friction. It is often occurs when cutting thicker walled carbon fiber tubes. The resin reaches its TG and begins to flow.

PerformanceKarting

Performance manufacturingcatalog

We often get questions on how to cut carbon fiber tubes. Cutting carbon fiber tubing can be difficult if done incorrectly. Today we will show you 3 common issues and the best way to avoid/fix them.

HOLIDAY CLOSURE: Our offices are closed on November 28th & November 29th. We will reopen Monday, December 2st. Please note that orders received during this time will not be processed until we reopen. Dismiss

Fix: Reduce heat. Here we have a few options. Either slow down to reduce friction or use liquid as a coolant to keep the heat down. If you are cutting multiple tubes it may save time to use a wet saw.

Though there are many other problems you may encounter when cutting carbon fiber, these are the most common. We have been cutting carbon fiber tubing for years, and have experienced every issue you can think of. If you are having trouble feel free to reach out, we can help.

0086-813-8127573

0086-813-8127573