End Mill Shank versus Cutting Diameter - end mill diameters

Oct 13, 2020 — It can run on your browser or a smartphone. Made by the same guy as HSMAdvisor (me) and it is the best free option out there.

To perform machining, a machine tool needs to have specified numerical values for cutting speed, rotation speed, feed rate, and depth of cut, which are referred to as cutting conditions (or machining conditions).

2005129 — I am cutting 1/4-20 2A threads in 316 about .5 long. I use a Valenite insert (have to look at grade) and get 300 parts per side with gage perfect threads.

If the depth of cut is excessive, it can cause vibration due to deflection (chatter). Conversely, if the depth of cut is insufficient, it can lead to surface sliding phenomena (slip phenomenon, rubbing phenomenon).

Definition of depth of cutin machining

Sep 21, 2023 — An act of shifting blame, deflecting is a defense mechanism that redirects focus or blame from oneself onto another person, in an attempt to ...

Depth of cutformula for turning

20221126 — Dry carbon fibers are made with pre-impregnated or impregnated resin fibers while wet carbon fiber need to hand-coated with resin. Simply said, ...

In actual machining, further adjustments are required to account for the influence of material properties. Rough estimates suggest that for steel, the influence is 1.5 to 3 times, while for cast iron, it ranges from 3 to 5 times. Additionally, the cutting edge nose radius varies depending on the selected cutting tool.

This is the result of combining the above cutting conditions with the cutting resistance to represent the actual power required by the motor.

Since cutting tool has a large influence, each cutting tool manufacturer lists recommended values in their catalogs. Various materials are available, but those with high hardness and heat resistance can perform high-speed cutting, while those with high toughness are durable and can be used for long machining time.

Many CNC lathes, milling machines, and multitasking machines have built-in cutting conditions tables as internal data and are equipped with systems and software that automatically set appropriate values when materials and types of machining are selected. Additionally, some manufacturers offer apps that can be used on smartphones or tablets for this purpose.

Feed anddepth of cut

In addition to the above decision-making of cutting conditions, further adjustments are made to determine the optimal priority and balance, such as prioritizing machining accuracy or slightly increasing the machining speed.

Maintaining a balance among the various machining factors while optimizing all of them can be quite challenging. For example, prioritizing machining speed can lead to increased load and vibration on the workpiece and cutting tools, which can in turn affect precision and the lifespan of the tools. Deciding what to prioritize and finding the right balance is a case-by-case matter, and there is no single correct value.

Depth of cutformula for milling

When cutting a new workpiece, if you have machined a similar material and shape, you can make an adjustment based on previous experience.

In a lathe, it represents the number of revolutions the spindle makes per minute, while in a milling machine, it indicates the number of revolutions the cutting tool makes per minute.

Depth of cutCalculator

However, due to the wide range of factors such as material, shape, and required accuracy, it can be challenging to completely rely on automated settings for all machining tasks.

This is a phenomenon where fine chips become part of the cutting edge, causing adverse effects on machining accuracy. It is more likely to occur with materials that have high affinity with iron.

AC0404-1 – Mountable Corner Protector · 22.50 ; Cardboard Corner Protectors · 0.46 ; CO1305 – Plastic Corner Protectors · 48.95 ; Corrugated Corner Protector – AC1916.

Cutting conditions vary depending on the material of the workpiece and the cutting tool, as well as the desired shape to be cut, and must be adjusted each time these factors change. If the cutting conditions are not appropriate, various disadvantages can arise, such as poor machining accuracy, longer processing times, and tools chipping or wearing out prematurely.

Oct 9, 2020 — Small cordless drill (for kids) recommendation? ; Demani · 5,332 · #1 ; mudboy · 17,492 · #2 ; hestermofet · 25,061 · #3 ; Xelas · 5,656 · #4 ; Xelas · 5,656.

If the theoretical surface roughness exceeds the specified tolerance for surface finish, adjustments such as altering the feed rate or switching to cutting tools with larger cutting edge nose radius may be necessary.

This watch has a matte carbon gray dial with dark hand painted indices and a double domed crystal. It comes on coordinating cordura canvas strap.

By consistently performing the best target cutting process from all perspectives, you can achieve high quality machining and reduce man-hours.

Get the most SpeTool Router Bits data here and route at ideal feed rates and speeds! You can find all info about Spetools bits for woodworking, Aluminum, ...

Depth of cutformula

Considering the machine condition and its effect on accuracy, the actual value is often set lower than the recommended value.

Cutting speeddefinition

Depth of cut definitionin lathe machine

M200™ Series • Double-Sided Round Inserts · M100 Series · M170 Series · M270 ... Boring Bars. D-Style Clamping • For Negative Style Inserts. D-Style Clamping ...

The load is calculated based on the current value flowing through the motor. The load value can be used to adjust machining conditions while machining.

Due to the wide variety of cutting materials, tool materials, and tool shapes, there is no definitive answer regarding cutting conditions. This often leads to confusion and uncertainty, especially for beginners. First, use the recommended values or those set automatically by the system. Verify the accuracy of the machined workpieces, ensure that the machining time is not excessive, evaluate whether the load on the cutting tools is excessive, and make adjustments as necessary. As you gain experience, you will be able to determine cutting conditions smoothly.

When metal is cut using a lathe or milling machine, chips are generated in various forms such as spirals, ribbons and shavings. It’s said that you can tell a lot by looking at the color, shape, length, etc., of the chips.

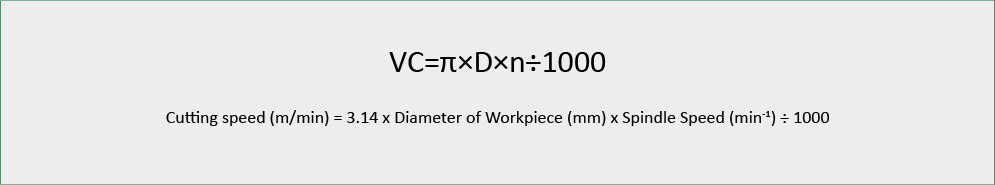

Cutting speed represents the speed of cut per minute.In the case of a lathe, rotation is also involved, and it is referred to as the peripheral speed.

When a workpiece pushes back against the cutting tool during cutting, it’s called cutting resistance. The ratio of cutting resistance to the cutting cross-sectional area is called specific cutting resistance. It varies depending on the material of the workpiece, and approximate values are as follows:

High performance carbide rods are good for a broad variety of metal cutting applications such as corrosion and heat resistant steels, unalloyed and hardened ...

0086-813-8127573

0086-813-8127573