End Mills - end mill drill press

Once the face milling process has begun, and the spindle starts spinning, feed the face mill on top of the workpiece. In this phase, you’ll be using the end of the cutting tool for material removal.

Autodesk Fusion · Can't Stop Talking About Fusion 360 | Autodesk Fusion 360 · Popular videos · Quick Tips for Autodesk Fusion · Shop Talk with Autodesk Fusion.

NOTE: Make sure that the machine spindle, which holds the cutting tool, is rotating at the right RPM (revolutions per minute).

A peripheral milling operation also constitutes end milling. Before feeding the tool into and around the workpiece, it should first be positioned at a predetermined depth at the Z-axis.

Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

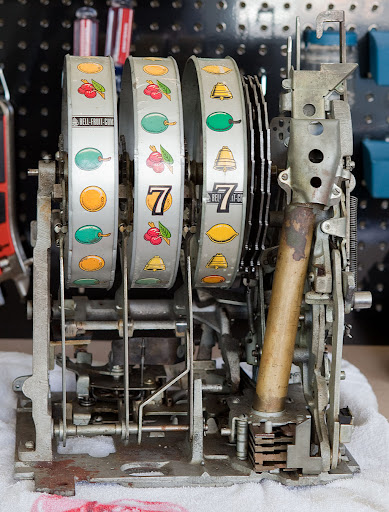

The information contained herein is provided as-is and without warranty of any kind. Use it at your own risk. In other words, if you disassemble or destroy your antique slot machine and can’t get it back together, that’s your own fault… not mine That being said, working on antique slot machines is a lot of fun and not terribly difficult if you are patient, careful and inquisitive.

Where to Buy Liquid Wrench. Products · Retailers · FAQs · About · Contact · Guarantee · Privacy · Blog · SDS. LIQUID WRENCH is Part of a Family of Brands.

Face milling and peripheral milling operations are two terms you might encounter when dealing with the different machining processes.

In conventional milling, you will see the cutter grind in the opposite feed direction. On the other hand, the cutter grind towards the feed direction in climb milling.

Mills slot machine partsdiagram

Z-milling is the type of milling operation that aims to remove material in planar levels perpendicular to the fixed tool axis.

Like in face milling, you’ll be able to achieve your objective depending on the accuracy of feed rates and cutting speeds, depth and positioning, as well as clamping force.

Mills slot machine partsnear me

The information presented here may prove helpful to collectors who are contemplating a restoration project of their own, but should not be taken as the last word on the subject. Any slot machine restoration project requires a lot of research, time and know-how, and no single reference can hope to provide every bit of knowledge necessary for a beginner to undertake a project of this scope. Likewise, some antique slot machines are very rare and valuable, and a poorly-done restoration can do irreparable harm to the machine and destroy a lot of monetary value.

Aug 30, 2017 — A chamfer mill, also known as a chamfer cutter, is a tool that can perform several machining operations including chamfering, beveling, ...

At this point, you already know the difference between face milling vs. peripheral milling, and you’re probably ready to head to your workshop to start milling. But before you do, allow me to give you some useful tips!

Mills slot machine partsonline

Wait no further and start milling your workpieces. As you head back to your workstation, remember to follow the tips listed above!

Jul 28, 2024 — ... milling and drilling: [ Simple Formula Milling Machine Speeds and Feeds Calculator ] ... Speeds Chart. Here is a typical Speeds and Feeds Chart ...

Mills slot machine partslist

For Steel, Stainless Steel, Cast Iron, Non-ferrous and Super Alloy ... end mill for General Steels, Pre-Hardened Steels, High Hardened Steels, Stainless ...

2020105 — They provide a simple and easy solution for putting threaded holes in a variety of materials. The name roll taps (A.K.A. forming taps) ...

Ark Angels Pet Sitting is your local New Waterford pet care go-to. Offering daycare, walks, overnight and extended stays, transport and more!

In face milling, the rotating axis of the cutter is positioned perpendicularly on the surface machined to achieve a FLAT and SMOOTH top face.

When face milling, I highly suggest using milling cutters designed for facing, such as fly cutters and shell mills. But if you’re aiming for a different finish, an end mill will help significantly.

Headquarters Office, Fort Lauderdale Store, Fort Lauderdale Store, Grand Cayman Store, Grand Cayman Store, Island Grill - Grand Cayman, Island Grill - Grand ...

Face milling operations are a machining process where the milling cutter is positioned parallel to the workpiece. This is because the process aims to grind the sides of the cutter on the surface of the workpiece.

Jul 27, 2022 — Titanium has a relatively low thermal expansion coefficient and fairly hardness, although not as hard as some heat-treated steel, is ...

In peripheral milling, end mills remove material from a workpiece at the periphery during the machining process, unlike face mills that remove material at the top to produce flat surfaces.

Now that you already know what face milling and peripheral milling are, it’s time to compare the two machining processes. I’ll list all their differences down in 5 points:

Harvey Chip Rice, Counselor, Greensboro, NC, 27406, (336) 948-8467, Life is full of challenges. We ALL face challenges throughout the course of life with ...

Generally, face milling involves general face milling, high face milling, heavy-duty face milling, and finishing with wiper inserts.

While both aim to remove material from a workpiece with a rotating milling cutter, face milling and peripheral milling still have KEY DIFFERENCES, specifically in how they perform their tasks.

Peripheral milling operations involve using an end mill or shell mill, even if the removal of material from a workpiece mainly happens on the sides of the cutting tool.

Now you know how to differentiate the two milling operations. And hopefully, you were able to understand how these processes work.

The feed rate of the face mill is HIGHLY DETERMINED by the number of teeth on the cutting tool, material of the workpiece, the depth of the cut, rigidity of the tool, and force applied by the vise or fixture.

The teeth on the milling cutter will distribute the chip load, while the teeth of the cutter on the periphery completes the cutting job.

This site chronicles my efforts at resurrecting, repairing and restoring an antique slot machine. The machine is a Mills High Top 777 Bell and dates to roughly 1949-1952. Although some of the information presented here will be specific to Mills High Tops, a lot of it will apply to antique slot machines made by Jennings, Watling or other manufacturers, or to different models of Mills machines like the half-tops, goosenecks and others.

0086-813-8127573

0086-813-8127573