End Mills - Page 1 - ball end mills

In observance of Thanksgiving, DATRON Dynamics will be closed from November 28th - 29th, 2024. There will be no shipping during this time. We will return to normal operations on Monday, December 2nd.

Capacity, 1-1/4 Inch Shank Diameter, 2-3/4 Inch Shank Length, Chrome. Part No 63836. Whether you're taking a boat to the lake or a camper across country, you ...

It is known that the volume formula of a circle is diameter×diameter×0.7854×length or radius×radius×3.1416×length. That is, d2×0.7854×L or R2×3.1416×L

Product Line. ALL; STANDARD LENGTH; MICRO SERIES TOOLS; STUBBY LENGTH; DRILL AND DEBURRING; CUSTOM DEBURRING TOOLS.

EndMill

Apr 10, 2020 — Hardenability curves are constructed from the results of Jominy Tests. Examples of a few steel alloy curves are shown in Figure 4. With a ...

202345 — 135-140 is the new 118. If you need to spot, use a 142° spot drill, to center the point without beating up the edges. Chamfer the hole after.

BIG KAISER is a global leader in premium high-precision tooling systems and solutions for the metalworking industries.

Endmilling

U.S. Congress - ZIP Code 67147 · District 04 - U.S. Representative · ZIP Code's Voting Stats for Last Presidential Election · KS - U.S. Senate · KS - U.S. Senate.

In observance of Christmas, DATRON Dynamics will be closed on Tuesday, December 24th, 2024. We will return to normal operations on Thursday, December 26th.

May 16, 2022 — By Steve Barrett,Creative Content Writer for Hilltop Packs LLC Jake and Ashley Yates of Waynesburg are living proof that big goals, ...

Cyber Week Sale On DATRON Tools! Use Code CYBER23 for 15% Off Complimentary DATRON gift with orders of $1000 For US Customers Only

1. Calculation and tolerance of external thread pitch diameter of 60° tooth type (national standard GB197/196)a. Calculation of the basic size of pitch diameterThe basic size of the pitch diameter of the thread = the major diameter of the thread – pitch × coefficient value.Formula representation: d/D-P×0.64952. Calculation and tolerance of pitch diameter of 60°internal thread (GB197/196)a.6H level thread pitch diameter tolerance (based on thread pitch)Upper limit:P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180P1.25+0.00P2.0+0.212P2.5+0.224The lower limit value is “0″,The upper limit calculation formula 2+TD2 is the basic size + tolerance.For example, the pitch diameter of M8-6H internal thread is: 7.188+0.160=7.348 Upper limit: 7.188 is the lower limit.b. The calculation formula of the pitch diameter of the internal thread is the same as that of the external threadThat is, D2=D-P×0.6495, that is, the middle diameter of the internal thread is equal to the major diameter of the thread-pitch×coefficient value.c.6G class thread pitch diameter basic deviation E1 (based on thread pitch)P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032P1.75+0.034P1.00+0.026P2.5+0.0423. Calculation and tolerance of major diameter of external thread (GB197/196)a. The upper limit of the 6h major diameter of the external threadThat is, the thread diameter value example M8 is φ8.00 and the upper limit tolerance is “0″.b. Tolerance of the lower limit value of the major diameter of the 6h class of the external thread (based on the thread pitch)P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265P2.0-0.28P2.5-0.335Calculation formula for the lower limit of the major diameter: d-Td is the basic dimension of the major diameter of the thread – tolerance.4. Calculation and tolerance of small diameter of internal threada. Calculation of the basic size of the small diameter of the internal thread (D1)The basic size of the small diameter of the thread = the basic size of the internal thread – pitch × factor5. Calculation formula of dividing head single dividing methodCalculation formula of single division method: n=40/Zn: the number of revolutions that the dividing head should turnZ: Equal fraction of workpiece40: fixed number of dividing head6. Calculation formula of hexagon inscribed in a circle① Find the hexagonal opposite side (S surface) of circle DS=0.866D is diameter×0.866 (coefficient)② Calculate the diameter of the circle (D) from opposite sides of the hexagon (S surface)D=1.1547S is opposite side×1.1547 (coefficient)7. Calculation formula of hexagonal opposite sides and diagonals in cold heading process① Find the opposite angle e from the opposite side (S) of the outer hexagone=1.13s is opposite side×1.13②Find the opposite angle (e) from the opposite side (s) of the inner hexagone=1.14s is opposite side×1.14 (coefficient)③ Find the material diameter of the head of the opposite corner (D) from the opposite side (s) of the outer hexagonThe diameter of the circle (D) should be calculated according to (the second formula in 6) the hexagonal opposite side (s surface), and the offset center value should be increased appropriately, that is, D≥1.1547s. The amount of offset center can only be estimated.8. Calculation formula of square inscribed in a circle① Circle (D) to find the opposite side of the square (S surface)S=0.7071D is diameter×0.7071② Find the circle (D) from opposite sides of the square (S surface)D=1.414S is opposite side×1.4149. Calculation formula of square opposite sides and opposite angles in cold heading process① Find the opposite angle (e) from the opposite side (S) of the outer squaree=1.4s is the opposite side (s)×1.4 parameter② Find the opposite angle (e) from the opposite side (s) of the inner squaree=1.45s is the opposite side (s)×1.45 coefficient10. The formula for calculating the volume of a hexagons20.866×H/m/k means opposite side×opposite side×0.866×height or thickness.11. Calculation formula of volume of frustum (cone) body0.262H(D2+d2+D×d) is 0.262×height×(big head diameter×big head diameter+small head diameter×small head diameter+big head diameter×small head diameter).12. Calculation formula for the volume of a spherical body (such as a semicircular head)3.1416h2(R-h/3) is 3.1416×height×height×(radius-height÷3).13. Calculation formula for machining dimensions of taps for internal threads1. Calculation of tap major diameter D0D0=D+(0.866025P/8)×(0.5~1.3) is the basic size of tap large diameter thread + 0.866025 pitch ÷ 8×0.5 to 1.3.Note: The choice of 0.5 to 1.3 should be confirmed according to the size of the pitch. The larger the pitch value, the smaller coefficient should be used. On the contrary, the smaller the pitch value, the corresponding larger coefficient should be used.2. Calculation of tap pitch diameter (D2)D2=(3×0.866025P)/8, that is, tap diameter=3×0.866025×pitch÷83. Calculation of tap diameter (D1)D1=(5×0.866025P)/8 is the tap diameter=5×0.866025×pitch÷814. Calculation formula for the length of materials used for cold heading forming in various shapes

X in the formula represents the volume value of the required material;L represents the length value of the actual feeding;R/d represents the radius or diameter of the actual feeding.

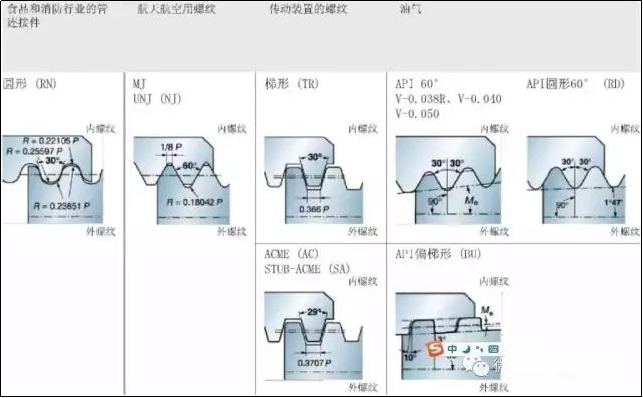

Everyone is familiar with the thread. As colleagues in the manufacturing industry, we often need to add threads according to customer needs when processing hardware accessories such as CNC machining parts, CNC turning parts and CNC milling parts.

1. What is thread?A thread is a helix cut into a workpiece either from the outside or from the inside. The main functions of threads are:1. Form a mechanical connection by combining internal thread products and external thread products.2. Transfer motion by converting rotary motion to linear motion and vice versa.3. Obtain mechanical advantages.2. Thread profile and terminologyThe thread profile determines the geometry of the thread, including the workpiece diameter (major, pitch, and minor diameters); thread profile angle; pitch and helix angle.1. Thread terms① Bottom: The bottom surface connecting two adjacent thread flanks.② flank: the thread side surface that connects the crest and the bottom of the tooth.③Crest: The top surface connecting the two flanks.P = pitch, mm or threads per inch (t.p.i.)ß = profile angleϕ = thread helix angled = major diameter of external threadD = major diameter of internal threadd1 = minor diameter of external threadD1 = Minor diameter of internal threadd2 = pitch diameter of external threadD2 = internal thread pitch diameterPitch diameter, d2/D2Effective diameter of the thread. About halfway between the major and minor diameters.

DATRON now offers our premium precision CNC cutting tools, previously only available to DATRON machine owners, to the public. German-engineered to the highest specifications for unmatched performance.

PTSolutions, PTS Tools.

SD21.5-5D-C25, U Drill Bit with 10pcs WCMX040208 Inserts ... (WCMX040208 Carbide Insert For Drilling, with Coated Genral Use.);.

For those tricky undercuts, DATRON has a dovetail milling tool and t-slot mill. The dovetail milling tool can bevel and deburr the underside of a part, removing the need to flip the part over for a second operation.

When calculating, the volume X÷diameter÷diameter÷0.7854 or X÷radius÷radius÷3.1416 of the material required for processing cnc machining parts and cnc turning parts is the length of the material.

Buy New Mini Chamfering Tool 45 Degree Handheld Metal Deburring Trimming Chamfering Machine Pneumatic Beveling Machine Light Linear Air Chamfer Tool Arc ...

The geometry of the thread is based on the thread pitch diameter (d, D) and the pitch (P): the axial distance along the thread on the workpiece from one point on the profile to the corresponding next point. This can also be seen as a triangle bypassing the workpiece.vc = cutting speed (m/min)ap = total thread depth (mm)nap = total thread depth (mm)t.p.i. = threads per inchFeed = pitch2. Ordinary thread profile

0086-813-8127573

0086-813-8127573