End Mills - Standard 4 Flute Regular Length - Single End - common end mill sizes

HP tooling have come a long way with the way tool grinders have improved. One of the biggest issues for tool performance is harmonics that occur when you elevate your spindle RPM’s. To combat this, tool companies have designed tools using variable flute pitch and variable helix angle.

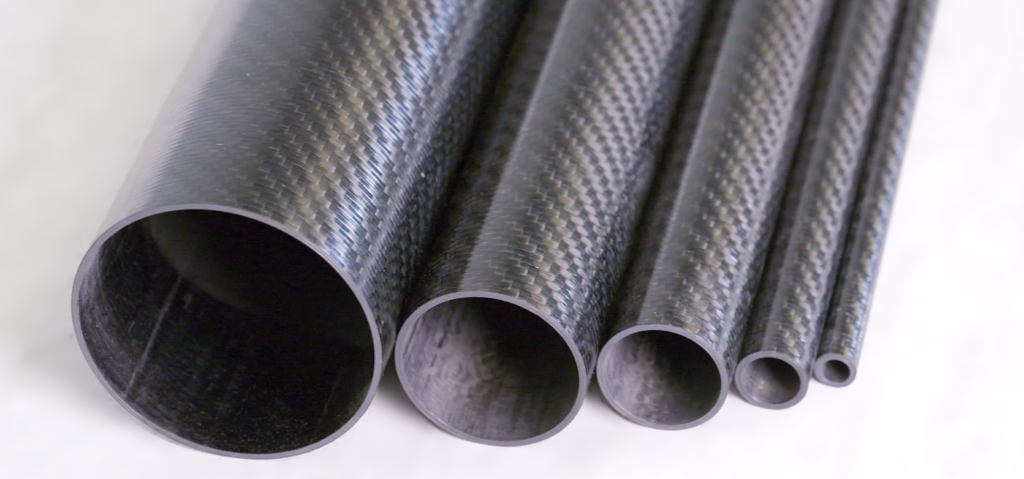

Clearwater Composites is an expert at carbon fiber and composite materials. We understand the materials down the fiber level and we know how best to tailor the carbon fiber design to achieve your needs. And, it is our intent to educate our customers, and the community at large, as best possible, as we strongly believe that the more engineers, designers, students, hobbyists and the public-at-large learn and understand about carbon fiber, the more widespread it’s use will become.

CFRPmaterialpropertiesPDF

Note: Properties of carbon fiber composites are dependent on the direction and the properties shown above are ONLY valid for one direction, typically referred to as the longitudinal direction.

HP tooling is specifically designed to optimize performance and productivity in demanding machining applications. These tools are engineered with advanced materials, specialized coatings, and precision geometries that enhance their durability, tool life, and cutting performance.

Because there are literally thousands and thousands of options when it comes to carbon fiber, it is impossible to list and explain all of the potential properties of carbon fiber.

CFRPmechanicalproperties

As mentioned above, non-ferrous typically best performs with a 2- or 3-flute on the end mill. When it comes to ferrous materials, you have many more options. Most companies have adopted a 5-flute end mill as their go-to for roughing and finishing versus the long-standing 4-flute end mill. In many cases, by using different programming strategies and HEM (High Efficiency Machining) or Dynamic milling techniques, you can increase your flute count.

It is important to determine your priorities when selecting end mills, as there are many ways to improve your overall costs. Our Good-Better-Best strategy allows us to dial in the best option from our deep selection of end mills.

It could be that you have many components to make, or very few, but the components require a great deal of metal removal. Maybe your component is very expensive, and you can’t afford any quality issues or scrap. Cycle time savings are often important, and you measure your cost per piece versus the sticker price of the tool.

When you have a new job, and before you go to the old faithful 4-flute end mill you have been using for many years, we would like you to ask yourself a few questions:

Cfrp propertiesand applications

Specific geometry, edge prep and coating is applied to the end mill to improve the overall performance you will achieve, for example:

Cfrp propertieswikipedia

Disclaimer: This data and information shown should only be used for comparison purposes. It should not in any way be used for design purposes as actual properties will vary based on many factors including, but not limited, to material variation, loading conditions, environment exposure and others. The end user is ultimately responsible for ensuring the use of our products and/or information is safe for their application. Clearwater Composites, LLC strongly urges users of our products and/or information to seek suitable engineering guidance, including but NOT limited to determining an appropriate factor of safety, when using our products and/or information for any application.

We just touched on a few of the variables to consider when thinking about HP end mills but there are many more that our team consider before selecting the best tool. There may be instances in your applications that our experts can find inefficiencies that may seem redundant on the surface, but could improve your production rate significantly. Triumph Tool’s team thinks outside the box with our solutions. This can tremendously increase your company’s productivity and reduce annual spending.

CFRPdensity

To new users of carbon fiber, understanding the properties of carbon fiber is often challenging. To some, it is a mysterious material. This is why we are here.

When you partner with Triumph Tool, you will work with a tenured technical representative that has the knowledge, expertise, and a wide range of tooling solutions available to find the perfect high-performance solid carbide end mill for your specific application.

Have you considered using a 7-flute or more for semi-finish or finish applications? When you consider this as an option, it opens some of the following benefits:

When selecting a carbon fiber product or designing with carbon fiber, one of the most important considerations is knowing the direction of the property of interest. Unlike metals, carbon fiber, and composites in general, are called anisotropic materials. This means the properties of the material are directionally dependent. For an easy analogy, think of a piece of wood. The strength of wood is dependent on the orientation of the grain. This is true with carbon fiber – the strength of the carbon fiber is dependent on the orientation of the fiber (grain). On the other hand, metals, plastics, and most common materials have the same properties in every direction. They are called isotropic materials.

CFRPuses

Nevertheless, the table below is shown for comparison purposes to help the end-user get a better understanding of the properties of the more common laminate designs of carbon fiber products sold by Clearwater Composites. The properties of other common materials, like steel and aluminum, are also shown for comparison purposes.

Carbon fiber reinforced polymer PDF

All of the factors above, or design options, are a unique advantage of carbon fiber and advanced composite materials. A part using carbon fiber can be tailored and designed for a specific application. The fiber type, fiber amount, fiber orientation, etc can all be changed to achieve certain properties, whether for mechanical reasons (strength, stiffness) or for other reasons, such as low CTE (coefficient of thermal expansion). Metals and other materials do not have this tailor ability. For example, on a metal part, the only thing that can be changed is the grade or alloy of metal and it’s thickness or shape. That’s it.

We at Triumph Tool work with our customers every day on all of these issues and more. This is the value you receive free of cost when doing business with us.

Cfrp propertiesand uses

As mentioned, there are more than a few factors to consider when deciding on what end mill to choose. Let’s look at some key characteristics that differentiate high-performance (HP) versus general-purpose (GP) tooling.

HOLIDAY CLOSURE: Our offices are closed on November 28th & November 29th. We will reopen Monday, December 2st. Please note that orders received during this time will not be processed until we reopen. Dismiss

In addition to being directionally dependent (anisotropic), there are many other factors in determining the properties of carbon fiber. Some of the key factors are:

Privacy Policy | Sitemap Additional accessible formats for this information are available upon request. Contact Us for more information.Copyright © 2022 Triumph Tool Ltd. All Rights Reserved.

Switching to a high-performance solid carbide end mill can easily improve these variables. If you are using a generic end mill, chances are, there is plenty of room for improvement in these areas and therefore, can lead to saving in annual spend when investing in the correct tooling. Contact Triumph Tool today to help find you the optimal solution for your specific application.

0086-813-8127573

0086-813-8127573