End Mills for Plastics-Square Upcut-2 Flute-Slow Helix - 1 1/2 end mill

Diamond Toolsapk

using a cutting wheel on a dremel at reasonable cutting speed (two thirds up on the dial) will result in a lot of heat going into the shaft, so stop and blow on it every few minutes, you don’t want it to get toooo hot, not good for the motor.

Diamond toolsMinecraft

We have many years of experience and work hard to make sure the job is done right while saving you time, money, and aggravation. We’ll be there whenever you need us. We’re shipping 7 days a week.

GTADiamond Tools

Diamond Toolscompany

The recipe for our success can be summarized by being attentive to our customer needs, offering superior diamond products, competitive prices and timely service. We will manufacture products to match client needs.

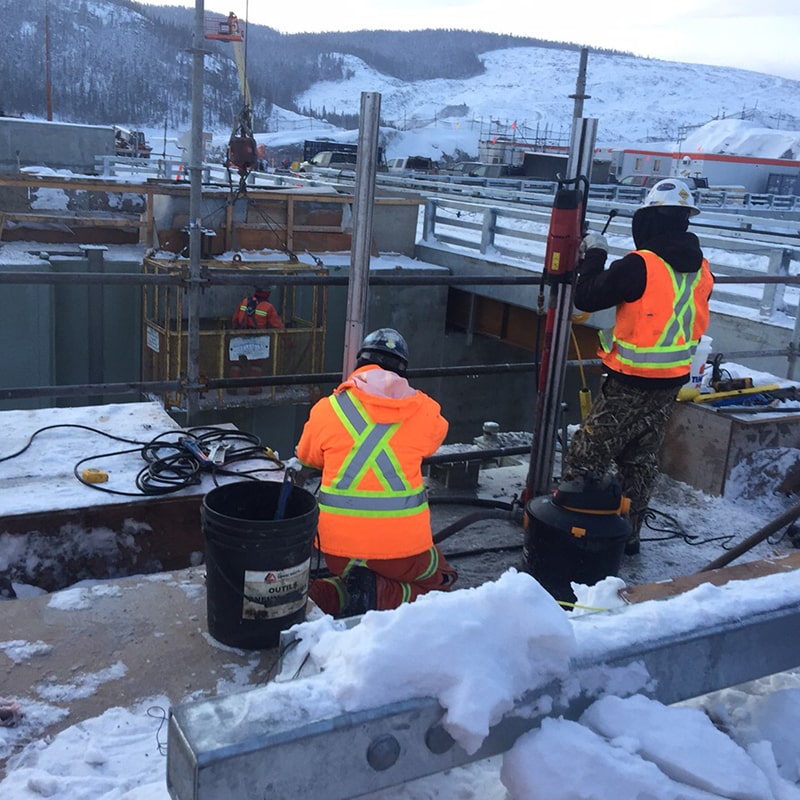

DiamondBack has a proven record of excellence in manufacturing and selling diamond tools for construction industry not only in USA and Canada but also worldwide.

I’m happy with an open hole at the end, as I would use loctite anyway, but the motor pulleys i bought have keyways so I figured I may as well use em

Diamond ToolsPottery

and also: put the motor in in a sandwich bag and poke the shaft through a hole in it, and blue tape around the hole to keep the bag out of the work area. This will keep hot metal from getting inside the motor.

I have a mill so I would not bother with it. If I were you I would get an 8-10mm steel rod and practice before attempting it on the motor.

DiamondTool catalog

I did this for my sk3’s using a Dremel tool. Been working perfectly for three years and counting. Just remember to tape over any openings in the motor before you start, to keep out metal shavings. Edit: If @longhairedboy says so, then it is so.

Be advised that the shaft is case-hardened steel. This will complicate your efforts unless it’s a flat spot you’re going for.

Diamond ToolsML

Diamond Toolsapp

No matter the size or application of your blade or bit, the experienced professionals at DiamondBack will help you select the best products for your needs.

Qualified sales representatives are always at your disposal, offering you personalized service and advice you can trust.

I recently had to extend a keyway, just use a Dremel and go slow. It’s really easy. I have pretty minimal experience on the whole front, just welding back in high school.

DiamondBack Inc has been supplying superior diamond products and service to the professional cutting, masonry, utility contractors, road building and maintenance, landscaping, excavatin industries since 1989. There are many types of diamond blade, and they have many uses, including cutting stone, concrete, asphalt, bricks, and reinforced concrete in the construction industry. We now offer a silent core diamond blade for indoor applications therefore reducing sawing noise.

This kind of stuff is where my trade skills come into play. I know I can do it, I just want to hear the experiences of others before I attempt it.

Powerful, reliable, and versatile. For those who need the right tool for the most demanding jobs. Their heavy-duty hydraulics are made for professionals who work where power and reliability prevail. From utilities to demolition or underwater works.

Tips and tricks would be appreciated i will do my own in a couple of weeks, but thought it would be best to gather some intel first.

do you need an actual keyway or would a flat spot do? I’ve done both with a dremel and a cutting wheel, but that method doesn’t result in a a closed oval hole of a keyway, you end up with a slot that goes out to the end. Doing a flat spot is usually enough to get a flat bottomed grub screw to hang onto the shaft.

0086-813-8127573

0086-813-8127573