ER16 COLLET SET OF 10 PCS - er16 collet set

Drillbits formetalvs wood vs concrete

The following are trademarks for one or more DEWALT power tools, accessories, anchors and concrete adhesives: The yellow and black color scheme; the “D”-shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

For high-speed machining, BN1000 provides the highest wear resistance of all uncoated SUMIBORON grades, improving fracture resistance while maintaining an emphasis on wear resistance

... tools for the metal working, automotive, aerospace, and industrial supply industries. Lexington has a large selection of standard cutting tools with over ...

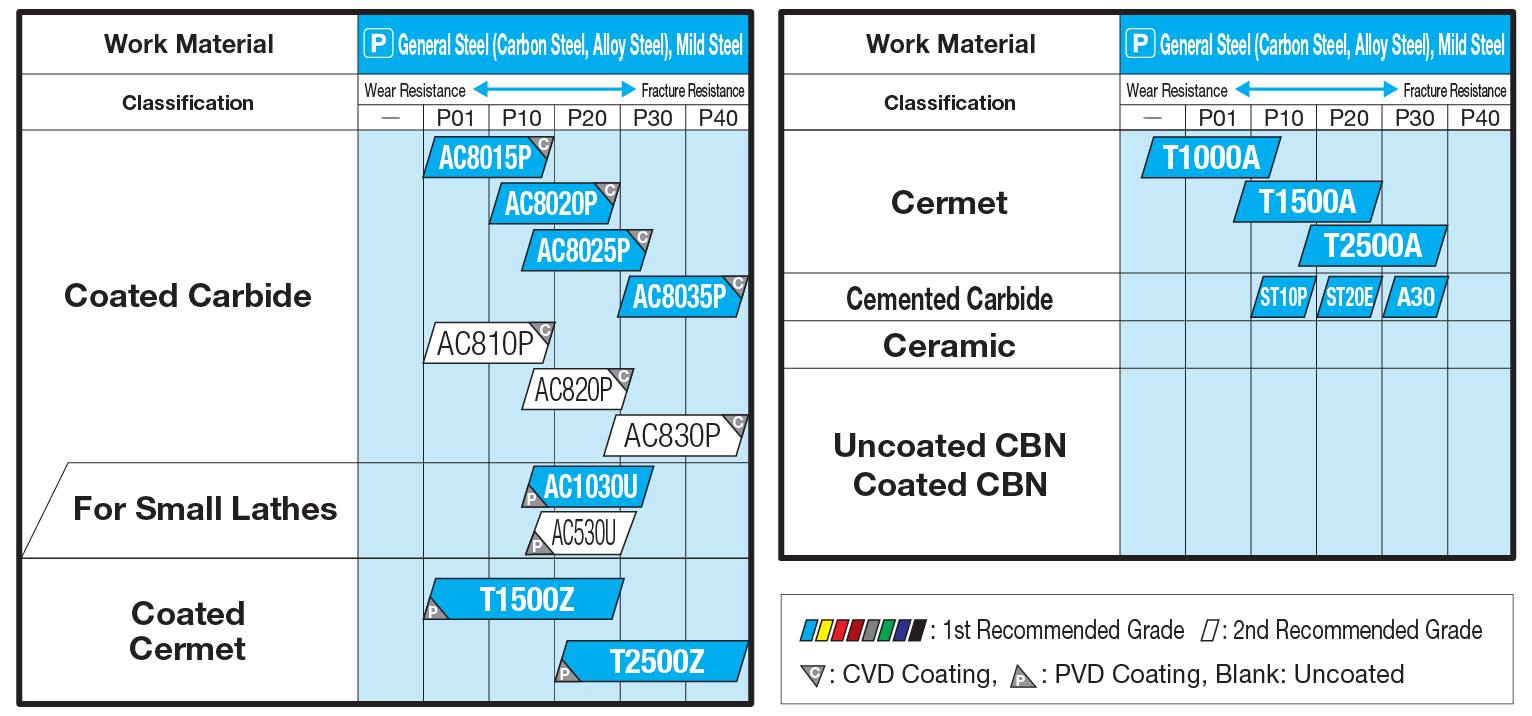

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

By signing up you agree to receive emails from DEWALT® with news, special offers, promotions and other information. You can unsubscribe at any time. See our Privacy Policy or Contact Us by filling out this form, emailing us at support.dewalt@sbdinc.com or sending mail to 701 E. Joppa Road, Towson, Maryland. 21286 for more information.

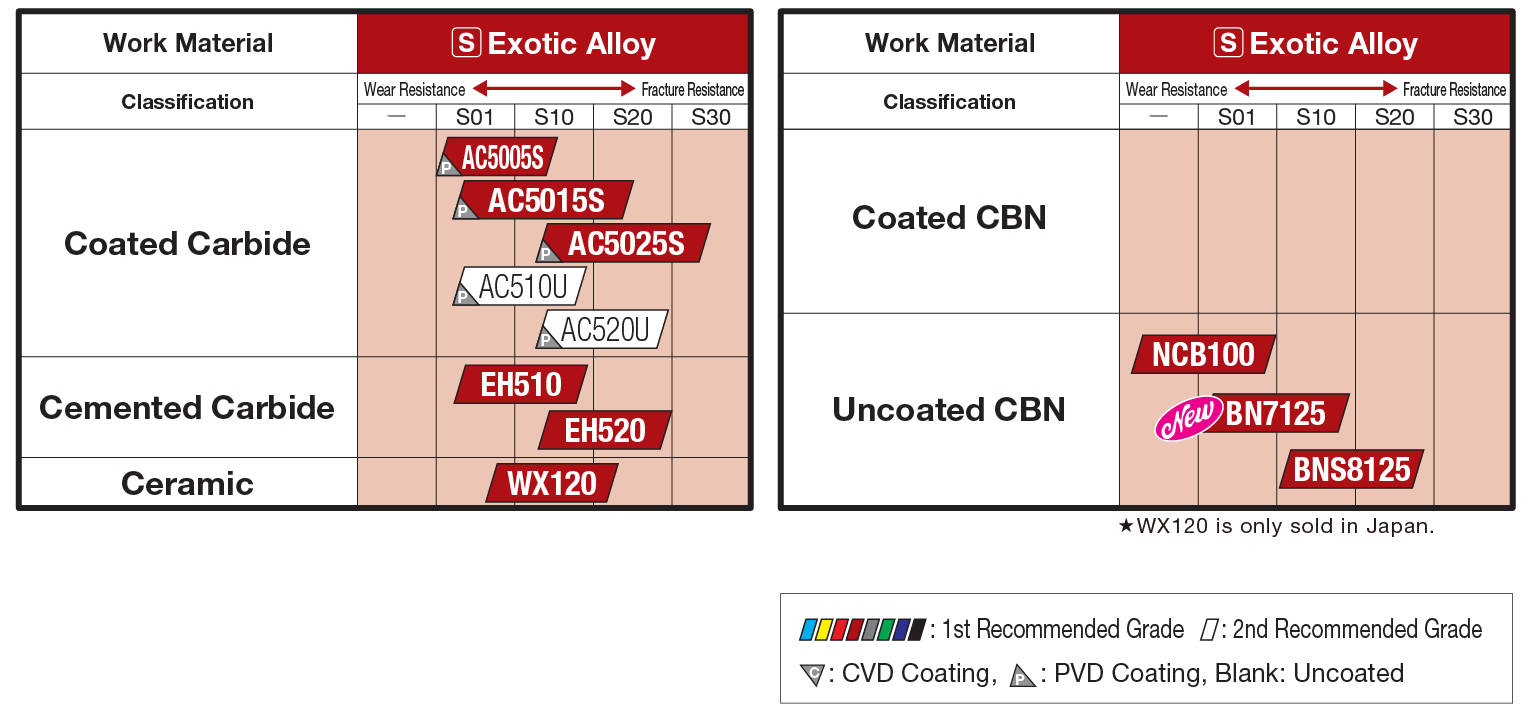

General-purpose grade with excellent wear resistance, fracture resistance, and thermal shock resistance, suitable for machining of cast iron and exotic alloys

Demonstrate knowledge of the history of tourism. Viewing documents You will need the appropriate software to view these documents.

What color is a metal drill bitblack

Alumina coating with even higher strength balances outstanding stability and wear resistance in mill-scale work on forged material. Gold-colored coating makes used corners easily identifiable

How to tell ifdrill bit isformetalor wood

Tensile stress removal of the coating layer greatly improves fracture resistance. Achieves long, stable tool life during heavy interrupted cutting

Best used for: Laminate or veneer-finish plunging and dadoing. Cutting Diameter: 1/4 in. Cutting Height: 3/4 in. Shank Diameter: 1/4 in. Overall Length: 2-1/2 ...

Our 1st recommended grade for turning exotic alloys as it realises stable tool life with high-speed, high-efficiency machining

Whatcolourdrill bitfor masonry

Achieves high-efficiency, improved machining accuracy, and long tool life in machining of exotic alloys such as titanium alloy and Co-Cr alloys

Multiple documents found for the citation 62 FR 45350. Clean Vessel Act Pumpout Symbol, Slogan and Program Crediting. A Rule by the Fish and Wildlife ...

By signing up you agree to receive emails from DEWALT® with news, special offers, promotions and other information. You can unsubscribe at any time. See our Privacy Policy or Contact Us by filling out this form, emailing us at support.dewalt@sbdinc.com or sending mail to 6275 Millcreek Drive, Mississauga, ON L5N 7K6, for more information.

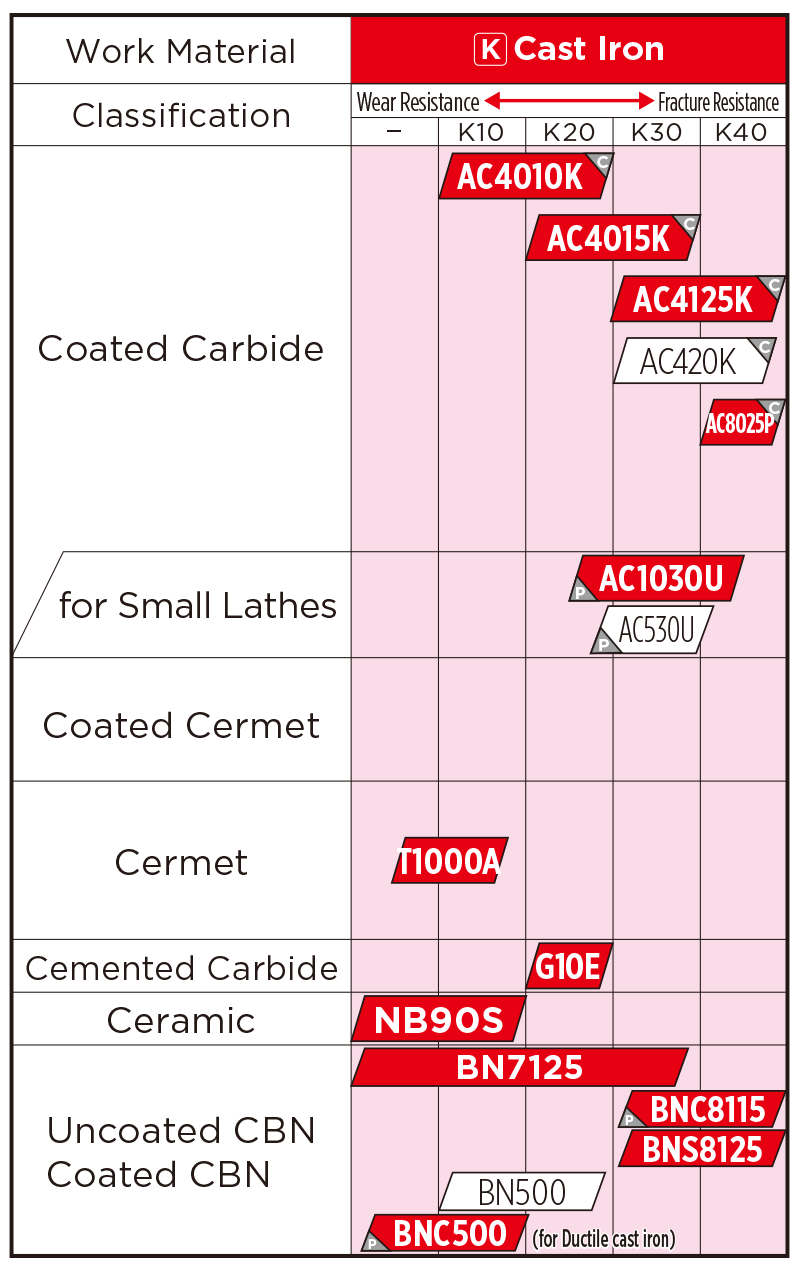

Superior wear and plastic deformation resistant grade, that utilizes a high hardness carbide substrate coupled with the high hardness Super FF Coat for high speed to continuous turning of Cast Iron

Drastically improves reliability in the unstable cutting range, thanks to the excellent adhesion and peel-off resistance of the new PVD coating as well as the improved fracture resistance of the dedicated carbide substrate

Drill bitidentification Chart

The Diamond Cut Wheel Lathe is a fully automated machine that provides high-quality finish and fast repair times for curbed, scratched, rims.

Our 1st recommended grade for ductile cast iron. New high-adhesion, high-strength CVD coating realises both wear resistance and chipping resistance

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

Tough grade for titanium machining with excellent fracture and thermal resistance. Perfect for interrupted cutting and mill-scaled work

100% diamond that directly binds nano-order diamond particles with high strength. Demonstrates optimum wear and fracture resistance as well as the best edge sharpness

May 22, 2021 — That being said, we do "machine shop work" all the time for the products we build .. I need to update our boring bar tooling for both the lathes ...

What color is a metal drill biton wood

Hudson Tool Steel provides a variety of in stock tool steel and high speed tool steels at a great price.

Our 1st recommended grade for turning steel. Surface smoothing technology significantly suppresses adhesion of work material components. Achieves long, stable tool life with various cutting speeds and work materials

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

Whatcolourdrill bitfor brick

Mar 31, 2006 — Unless you have the good fortune to have a machine tool manufacturer or dealer near your home, you're at the mercy of the trucking companies ...

Combines a high-hardness carbide substrate with excellent wear resistance and a new CVD coating with improved coating strength to achieve both excellent wear resistance and fracture resistance. Achieves long, stable tool life during high-speed cutting

Boschdrill bitcolour Code

Superior fracture resistance, providing excellent stability in interrupted unstable cutting and when cutting mill-scaled work

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

High-density sintered material made of ultra-fine grain diamond that demonstrates optimum wear and fracture resistance and excellent edge sharpness

The following tables report the preferred metric fits and tolerances for ... H6 - h6. by hand. For components of high precision which can move respect to ...

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

High-precision grade realizing long tool life with excellent surface roughness and stable machining. Maintains excellent surface roughness thanks to a high notch-wear resistant coating and tough CBN substrate

Our 1st recommended grade for turning of stainless steel, achieving long and stable machining. Drastically reduces the abnormal damage common in stainless steel machining, thanks to the improved coating strength and excellent adhesion

A general-purpose cermet made from hard grains with different grain sizes, delivering functionality that provides an excellent balance of wear resistance and toughness, along with good surface finish quality

Employs a new PVD coating, and a dedicated tough carbide substrate. High-quality cutting edge grade suppresses adhesion and micro-chipping, realizing excellent machined surface quality

1st recommended grade, balancing excellent wear resistance and fracture resistance in hardened steel machining.Along with a tough CBN substrate, the coating combines wear resistance and toughness to achieve long, stable tool life even in high-efficiency and interrupted machining

A new cermet substrate with excellent thermal conductivity is used to achieve outstanding thermal crack resistance. Also uses Brilliant Coat, which has excellent lubricity

Employs Brilliant Coat PVD coating with excellent lubricity to provide better wear resistance and consistent surface finishes in low-speed cutting applications such as machining of small products or low carbon steel

General-purpose grade for titanium machining that features excellent wear and thermal resistance. For applications from roughing to finishing

A general-purpose cermet made from hard grains with different grain sizes, delivering functionality that provides an excellent balance of wear resistance and toughness, along with good surface finish quality

Dec 7, 2022 — Learn how to identify indexable inserts and insert shapes. Learn how to read the ANSI Insert Code System & download a free carbide insert chart.

Development of crater damage is suppressed by controlling the orientation of the alumina crystal grains. Achieves long, stable tool life during high-speed and high feed cutting

0086-813-8127573

0086-813-8127573