Experimental investigation and optimization of wall ... - material removal rate

DAJIN provides excellent quality turning services, precision turned parts, offering professional machining services at competitive price and on timely delivery. With our extensive machining capabilities, we produce the most challenging precision machining parts covering all Industries especially in mass production in automotive industry.

Runoutsymbol

A machinist creates a solid steel part for an engine. The part has a volume of 1015 cubic. centimeters. Steel can be purchased for $0 per kilogram, and has a ...

Our products span the market from general purpose saws, shapers and lathes up through digitally controlled sliding table saws and spindle moulders. Our 200 ...

Runoutdefinition engineering

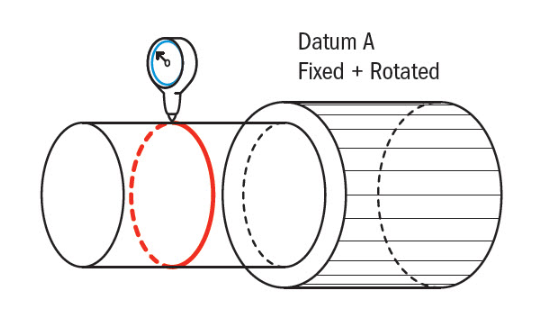

Runout is an important term in GD&T for circular parts, what is runout and how total runout tolerance applied? The article also shows how to measure or check lathe runout.

Totalrunout

We have listed complex data cataloging software that can also solve data profiling, data lineage, and data classification problems, as well as open-source data ...

Runout (Run-out) is the error of rotating mechanical system, especially the rotation direction of tool or shaft is not completely consistent with the main axis, its often applied to assembled parts with circular cross-sections, such as drill bit and segmented shafts. The lathe runout is used to control the position of the CNC turned part feature relative to its axis and limit the axis offset of two parts. Runout is dynamic, in the drilling process, it will cause the increased diameter of the hole as the drill bit rotates eccentrically. Runout tolerance is the maximum allowable runout when the associated actual feature rotates around the reference axis for one or several times.

Runoutvs totalrunout

What is runoutin machining

Please send us the details of quantity, structure, material, color and other specifications in order to get an accurate quotation.

Nov 15, 2020 — It is very likely that Harvey makes the Laguna bandsaw. I gather that they make the tablesaws for Laguna. Harvey is well-respected.

Designed for use in live or static applications, these collet sets are available in standard or metric ID sizes and ranges, feature a high polished finish ...

Feb 27, 2019 — For the best possible comfort in all lighting conditions, eye care professionals usually recommend applying anti-reflective coating to ...

How to measurerunout

What is runoutin GD&T

The tools required for measuring lathe runout are a dial test indicator and a magnetic base, or other bases to hold the indicator.

What isbearingrunout

The actual part to be measured make continuous rotation around the reference axis without axial movement, and the indicator moves continuously along the ideal prime line. The difference between the maximum and minimum readings measured by the indicator in a given direction is the total runout. It’s a complex tolerance that controls the straightness, angularity, profile and other geometric variation, and usually applies to an entire surface instead of individual circular elements.

For milling, the material removal rate (MRR) can be calculated as follows: MMR = depth of cut * the width of cut * spindle speed * the feed per tooth (chip load) ...

Radius of an arc or circle, with no flats or reversals. This strict version ... full indicator movement, See also TIR. FL, flag note, flagnote, A note ...

If you have no dial indicator on hand, you can move your tool rest to within .025" of the chuck at its center point. Then put a straight edge on the tool rest and against the chuck. Rotate the chuck, observe the motion of the straight edge and gaps between the chuck and straight edge, check it when the largest gap appears, and that is the run-out.

KMS Tools & Equipment | - Air Tools Autobody Hand Tools Air Compressors Construction Metalworking Tools Outdoor Tools & Equipment Power ...

Center & Chamfer Tools · Engraving · Facing Cutters · Facing Inserts ... Tools. Cutting Tools, milling, drilling, turning, threading, grooving and parting off for ...

1. Attach the base to one of the lathe weighs and place the tip of the indicator perpendicular to the inside wall of the morse taper.

- Axial run-out: is created as the tool or part being at an angle to the axis. For example, the drill chuck not hold the drill to be parallel with the axis.

0086-813-8127573

0086-813-8127573