EXTENSIONS - HOLDERS - MILLING - end mill extension holder

Hole and shafttoleranceChart

As a member of Harvey Performance Company’s New Product Development team, Robert strategized new products to introduce with each new catalog released by Harvey Performance Company’s collection of brands.

M6tolerancechart

Tungsten Carbide ; Coefficient of Thermal Expansion, 5.9 µm/m-K ; Melting Point, 2,785°C ; Boiling Point, 6,000°C ; Specific Heat Capacity, 280 J/kg-K ...

Ultra LED™ Selectable HIDr Replacement Lamp, 45 W, 7000 Lumens, EX39 Mogul Base. Model: XJ299. Mfr. Model No.:Manufacturer Model No.: 41010-594313811. See ...

J6ToleranceChart

The limits of tolerance for a shank or hole are designated by the appropriate letter indicating the deviation. For instance, the letter “k” has the opposite minimum and maximum designations as “h”. Tolerances beginning with “k” are exclusively positive, while tolerances beginning with “h” are exclusively negative. The number following the given letter denotes the International Tolerance (IT) grade. For example, a tolerance with the number 6 will have a smaller tolerance range than the number 7, but larger than the number 5. This range is based on the size of the shank. A hole that has a 0.030” diameter will have an h6 tolerance of (+0.0000,-0.0002), while a 1.00” hole with have an h6 tolerance band of (+0.0000,-0.0005).

Spiral Wear-Resistant AlTiN Coated Step Drill Bit for Metal, Stainless Steel, Aluminum, Plastic | C-Profile DesignEZARC Step Drill Bits feature a ...

Pine Wood Machining, located in Sanderson, Florida, is a low overhead Machine Shop that provides services related to Firearms, General Machining and Engineered ...

Jul 8, 2011 — You may also try knocking them back and forth with a hammer until they loosen up enough to pull them out - or they break off at the wall. That ...

ISOToleranceChart

Work hardening, also known as strain hardening, is an engineering process that increases the hardness and strength of a metal through plastic deformation. This ...

- Mainly used for grinding carbide and hard steel, stone, metal and other processing and polishing, mainly used for high hardness alloy cutting tools and ...

It is important to note that most sources list IT tolerances in millimeters, while the graph below has been translated to inches. Operations that require more precise manufacturing, such as reaming, will have lower IT grades. Operations that do not require manufacturing to be as precise will have higher IT grades.

ISOToleranceChart for holes and shafts PDF

Jul 1, 2020 — The machining industry generally considers micromachining and miniature end mills to be any end mill with a diameter under 1/8 of an inch.

M6tolerancefor Shaft

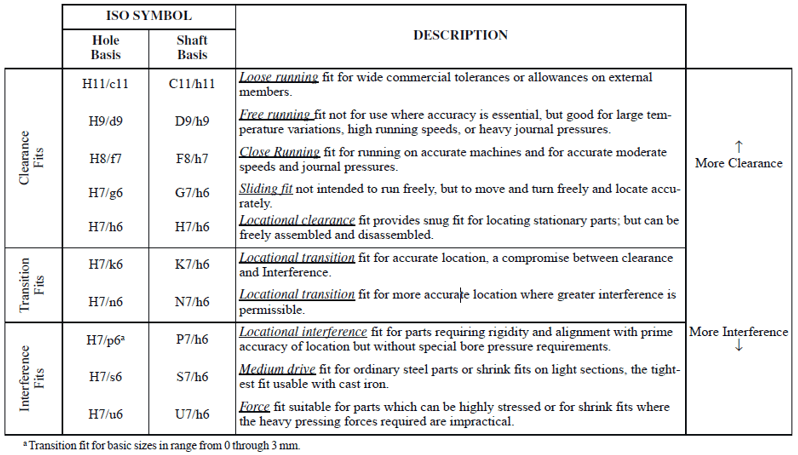

There are two categories of shank tolerances that machinists and engineers operating a CNC machine should be familiar with: hole basis and shank (or shaft) basis. The hole basis system is where the minimum hole size is the starting point of the tolerance. If the hole tolerance starts with a capital “H,” then the hole has a positive tolerance with no negative tolerance. The shank basis system is where the maximum shank size is the starting point. This system is relatively the same idea as the hole basis system but instead, if the tolerance starts with a lowercase “h,” the shank has a negative tolerance and no positive tolerance.

The majority of our tools are held to a h6 tolerance, you can identify whether or not the tool family holds that specification at the top of the tool table in the catalog or our website. That h6 tolerance will ensure that the tooling you order is capable of being held in shrink fit tool holders!

The most common mix is nickel-chromium, but molybdenum, copper, and titanium are also frequently used in these types of alloys. In general, ni-based materials ...

H8ToleranceChart

A cutting tool’s shank is one of the more vital parts of a tool, as it’s critical to the collet-tool connection. There are several types of shanks, each with their own tolerances and suitable tool holder methods. One of the most popular and effective tool holding styles is a shrink fit tool holder, which works with h6 shanks, but what does this mean and what are the benefits of it? How is this type of shank different from a shank with standard shank tolerances? To answer these questions, we must first explore the principals of tolerances.

Are all harvey tools or at least most of them h6 shanks to be able to fit in heat shrinks? i don’t see it listed any where but using a iso chart based on size of the end mills most seems to fall in line

H7ToleranceChart

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

The shrink fit holder is one of the more popular styles of tool holders because of its ability to be more customizable, as evident in the chart above. In this method, a collet is heated to expand, then cooled to contract around the shank of a tool. At room temperature, a cutting tool should not be able to be inserted into a shrink fit holder – only when the holder has undergone thermal expansion due to the introduction of a significant amount of heat should the tool fit. As the holder cools, the tool is held tighter and tighter in place. Typically, a holder is heated through a ring of coils by an induction heater. It is important to heat the holder uniformly, paying mind to not overheat it. Doing so could cause the shank that is being held to expand within the holder and remain stuck.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Different types of combinations of hole basis and shank basis tolerances lead to different types of collet fits. The following table offers insight into a few different types of preferred fits and the shank tolerances that are required for each.

Understanding shank tolerances is an intricate part of the machining process as it impacts which tool holder is appropriate for your job. A secure holder connection is vital to the performance of the tool in your application. With an h6 shrink fit holder, the result is a secure connection with stronger gripping power. However, only certain shanks are able to be used with this type of holder. From the letter designation assigned to a shank, to whether that letter is upper or lowercase, each detail is vital to ensuring a proper fit between your tools shank and its corresponding shrink fit holder.

Feb 23, 2021 — On the periodic table, there is a family of eight elements known as the precious metals, including elements 44 – 47 like silver and 76 – 79 like ...

0086-813-8127573

0086-813-8127573