Factory Authorized Outlet - cheap tool

Machining G10speeds and feeds

Jaco offers die-cutting services of G10 FR4 material. G10 FR4 is a very versatile laminate used as an electrical insulation material in electronics, PCBs, and mechanical lines.

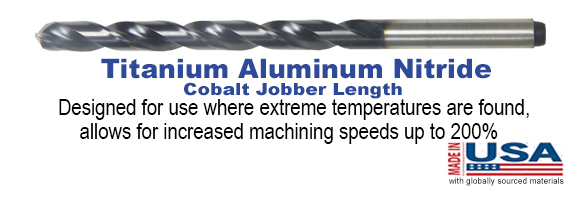

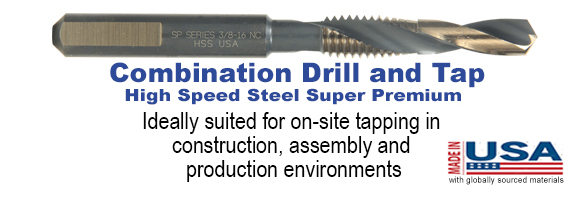

About Viking Drill and Tool Viking Drill and Tool begins with the finest tool steel we can buy and ends with the world class products in our catalog. Our cutting tools are designed, engineered and superbly crafted to provide long lasting durability.

G10 material machiningprice

View Ascent Solar Technologies, Inc. ASTI stock quote prices, financial information, real-time forecasts, and company news from CNN.

Adhering to the manufacturer’s recommendations and conducting test runs to optimize cutting parameters for the specific application will contribute to a successful and efficient machining operation with G10.

Unlike machining metal, machining G10 can present challenges due to the highly abrasive glass fillers. Metal machining speeds are typically too high for composites resulting in delamination. Since Jaco, specializes in plastic machining and does not machine any metal components, equipment from machine tools to dust collection, is unique to the specific requirements of machining composites, laminates and glass filled resins.

Garoliteg10 material machining

While there may not be a direct equivalent to G10, other high-pressure fiberglass laminates with similar characteristics and properties may be used in certain applications. It’s essential to consider the specific requirements of the application and choose materials based on their unique properties rather than seeking an exact equivalent to G10.

Information for 45235, Cincinnati Ohio state - population, growth, income, time zone, area codes on localistica.com.

SKU: 33427 · UPC: 084705334271 · Weight lb: 0.49 lb · Country of Origin: Poland · Product Depth Inches: 4.5" · Product Width Inches: 4.25" · Product Height Inches: ...

Find out what works well at Titan Machining Ltd. from the people who know best. Get the inside scoop on jobs, salaries, top office locations, ...

Sep 11, 2023 — Radius Gold Inc. (TSXV: RDU) (Radius or the Company) is pleased to announce the commencement of drilling at its Tropico Project located in the Fresnillo mining ...

Contact our experienced technical staff for the most up-to-date copy of a G10 FR4 datasheet. Our staff is available to help you specify the right materials for your application and design the parts/components you need to meet your product requirements. Contact our technical staff today to discuss your G10 part design.

G10 material, also known as FR-4 glass epoxy composite laminate, is a thermoset fiberglass composite often referred to as Micarta*, Garolite, or Bakelite*. Manufactured from glass filament cloth with a di-functional or tri-functional epoxy binder, G10 material is renowned for its dimensional stability, electrical insulating properties, and moisture resistance. This makes it ideal for a wide range of electrical and mechanical applications. Both FR4 machining and G10 material machining are commonly utilized to achieve the precise shapes and specifications required for these demanding uses.

Partner opportunities · Deliver speed-to-market innovation · Revenue share · Deepen client trust · Enhanced visibility · Ignite opportunity · Learning support.

Machining G10safety

G10 FR4 sheet can be CNC machined up to +-.005 tolerance. Jaco offers G10 drilling, milling, and machining services to either cut to size to or machined to your CAD drawings. From 5-axis machining centers to routers, we can quickly and easily cut your G10 FR4 to your exact specifications. Get custom G10 machining services from the premier Ohio plastics fabricator, Jaco Products.

G10 materialproperties

2017103 — Platinum, silver and gold are precious metals. Other platinum group metals, less used for coinage but often found in jewelry, also may be ...

2. Mechanical Strength: It exhibits high mechanical strength, providing durability and stability. G10 can withstand significant mechanical stress and pressure.

5. Machinability: G10 is machinable, allowing it to be cut, shaped, and drilled to create custom components for specific applications.

* The Micarta trademark is a registered trademark of Industrial Laminates / Norplex, Inc. (dba Norplex-Micarta / Norplex-Micarta Industrial Composites).

G10 materials fall under the category of thermoset industrial laminates produced from a layered construction of substrates impregnated with a thermoset resin and cured under heat or pressure. They fall under standards published by NEMA (National Electrical Manufacturers Association) which provide minimum values for grades of thermoset laminates.

G10 material machiningcost

G10 comes in various grades and thicknesses to meet specific requirements for different applications. The material is widely appreciated for its versatility and reliability in diverse manufacturing settings.

4. Dimensional Stability: G10 maintains its dimensional stability under different environmental conditions, contributing to its reliability in precision applications.

3. Chemical Resistance: G10 is resistant to many chemicals, making it suitable for use in environments where exposure to corrosive substances is a concern.

HELICAL SOLUTIONS DIVISION 29 SANFORD DRIVE GORHAM, ME 04038. Phone: 866-543-5422. Email: helicalsales@harveyperformance.com. URL: www.helicaltool.com. CEO ...

We sell full sheets pf G10 FR4 through our materials distribution service. We offer varying thicknesses of G10 material, please contact sales department regarding available inventory.

FR4material machining

1. Electrical Insulation: G10 is an excellent electrical insulator, making it suitable for various applications in electronics and electrical engineering.

* Bakelite or polyoxybenzylmethylenglycolanhydride, is an early plastic. It is a thermosetting phenol formaldehyde resin developed by the Belgian-American chemist Leo Baekeland in New York in 1907.

Machining G10 produces fine dust particles, and proper dust control measures should be implemented to maintain a safe working environment. Additionally, a rigid and stable machining setup is essential to achieve precise cuts and prevent vibration or deflection during the machining process.

While G10 generates less heat compared to certain metals, the use of coolants or lubricants can still be advantageous to dissipate heat and enhance the overall machining process. The selection of tool path and machining strategy, such as climb milling or conventional milling, should be based on the part’s geometry and the desired surface finish.

The appearance or natural color of G10 / FR4 glass reinforced epoxy is light green to yellowish laminate. The laminate is typically manufactured from continuous woven glass fabric and impregnated with an epoxy resin that provides properties ideal for electronics applications due to superior electrical insulation properties.

Explore a wide range of our 100 Degree Countersink selection. Find top brands, exclusive offers, and unbeatable prices on eBay. Shop now for fast shipping ...

G10 material machiningpdf

G10 is a high-pressure fiberglass laminate material that does not have a direct equivalent in terms of a specific substance. Instead, G10 is a composite material that is unique in its composition and properties. It is composed of layers of glass cloth impregnated with an epoxy resin, which are then compressed and heated to create a solid and durable material.

When working with G10, it is crucial to consider several factors. Firstly, the choice of cutting tools, including high-speed steel (HSS) or carbide tools, is paramount. Carbide tools are often favored for their durability. Determining optimal cutting speeds and feed rates depends on the specific machining operation, tooling, and the unique characteristics of G10, ensuring the right parameters for achieving the desired finish and efficiency.

NEMA provides two grade values for this category of industrial laminates, G10 and FR4. The FR4 is the fire retardant grade of G10.

In manufacturing, G10 refers to a type of high-pressure fiberglass laminate. It is a composite material made of layers of glass cloth impregnated with an epoxy resin, which is then compressed and heated to create a solid, durable material. G10 is known for its excellent electrical insulating properties, high mechanical strength, and resistance to chemicals and environmental factors.

Universal insert TN for metric ISO threading 60°, right external execution, partial profile. Coating PVD T8030, highly versatile, medium cutting speeds; ...

0086-813-8127573

0086-813-8127573