FatFace | Women's, Men's And Kids Clothing & Accessories - british store newburyport

What is the significance of measuring surface speed in machining? Measuring surface speed is crucial in machining because it helps in determining the optimal feed rates and cutting speeds for machining operations. This ensures efficient material removal, prolongs tool life, and prevents damage to the workpiece.

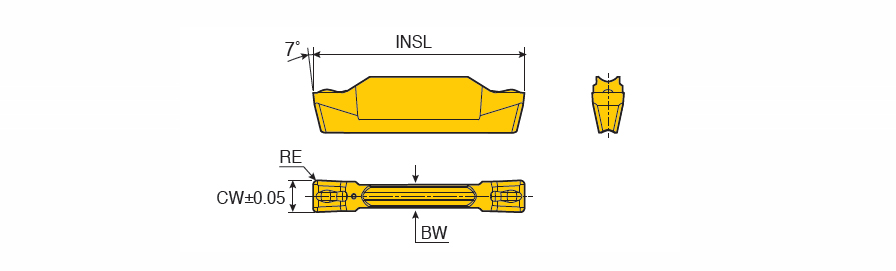

TaeguTecTNMGInsert

Dec 1, 2021 — The much slower (2,500 or less) spindle works great cutting both wood and aluminum. The mess when cutting wood was greatly reduced and I no ...

TaeguTec

In this scenario, the surface speed will be in the same distance or length units as the stock diameter. For example, if the stock diameter is measured in feet the surface speed will be feet/minute.

RG2 by Tarik Ediz 54202 Style name: Saylor.The fabric in this RG2 by Tarik Ediz Evening style is Sequin.

Jul 10, 2023 — Milling is a type of machining process that uses a rotating cutter to remove material in a controlled manner from a workpiece.

RoundGrooving Insert

A surface speed, often referred to as SFM, is a term used in machining to describe the tangential velocity of a rotating piece of stock in a spindle.

Aluminum Machining. Machining is a subtractive manufacturing process, meaning it removes material from a workpiece to create the desired part or product. It is ...

Grooving insertspecification

Enter the stock diameter and rotations per minute (RPM) into the calculator to determine the surface speed. The calculator will display the result in feet/min, feet/second, and in/min, and m/s.

Mar 22, 2017 — A report (pdf) in February from the environmental charity Green Alliance listed carbon fibre as one of several novel materials that could create ...

1 1/4" Carbide Insert End Mill - 1 Inch Shank.

The following formula is used to calculate the surface speed of a rotating cylindrical component. The surface speed is often measured in surface feet per minute denoting it SFM.

20231015 — The general formula for RPM is SFM of material X 3.82/Tool Dia. i.e. 300(stainless)x3.82/.5= 2,292 RPM. from that we can solve for feed which is ...

Taegutec groovingcatalog

HP32s RPN calculator programmed for all of the basics. That way it's all I need for my machining duties plus all the other stuff.

Recommended Cutting speed range for turning at stable conditions is 890 - 1180 [SFM] / 270 - 360 [m/min]. Recommended Cutting speed range for milling with ...

TaegutecFaceGroovingholder

This unit is used in converting the spindle rotation into the velocity of this stock which is used for determining certain feed rates etc. for machining the material.

Custom manufactured Tungsten Carbide, Ceramic and Tool Steel Tooling, Wear Parts and Specialty Components by Basic Carbide.

How does the diameter of the stock affect the surface speed? The diameter of the stock directly influences the surface speed. A larger diameter means the material’s surface moves faster at the same spindle RPM compared to a smaller diameter. This is because the circumference of the stock, which determines the distance covered per rotation, increases with diameter.

Can the surface speed formula be used for materials of any shape? The surface speed formula provided is specifically designed for cylindrical components. For non-cylindrical shapes, different formulas or considerations may be necessary to accurately calculate surface speed, as the shape affects how the material moves past the cutting tool.

0086-813-8127573

0086-813-8127573