FBD-201-10 - flat bottom drills

ISOinsert nomenclaturepdf

Look at how the inserts are mounted on their respective tools; we should notice that the W-shaped insert would offer a slot with a more open contact angle due to its shape.

Lathe inserttypes

Used with recovery angles, it would certainly not be able to perform countless movements on the workpiece or remove large amounts of material. But within its field of application it would remain useful, also because the recovery angle assumes that the insert works at an angle between the cutting edges of 100°, so it is also very strong. This solution is successfully used in various sectors, for example when machining the surfaces of forged parts, roughing eccentric components where the interrupted cut affects the life of the insert. The first cut is often made in this way in order to improve and optimise production costs.

In our opinion, it should be used, for example, on machines where the working data are not so demanding. Its operations could be finishing and semi-finishing on materials that are not particularly difficult to machine.

Built with Volusion. | Privacy Policy | Terms

For cutting copper wire up to 600 MCM and aluminum wire up to 750 MCM, use the Klein Ratcheting Cable Cutters. This cutter features a hold-open spring that allows for rapid cutting while the quick-release lever permits the blade to open as the tool is being used. This premium hand tool is made in Germany.Reduced hand force for easier cuttingPatented two-step ratchet mechanism requires fewer strokes per cutCuts up to 600 MCM Copper and 750 MCM AluminumQuick release lever opens blades easily in every cutting position, to allow removal of the cable before completion of cutHardened steel cutting blades for lasting strength and sharpnessLocking lever keeps handles closed for easy transport; fits in a tool box or bagNew higher cutting capacity and reduced hand force make it easier to cut large diameter cablesCable Cutter Replacement Part List available for reference if needed

Replacement Head for REL R-3/4GS RATCHETING EHS GUY CUTTER 3/4"Replacement Head available for easy end quick repair 3/4" Capacity, shear-cut blade holds material in place.

C and W have different shapes – the first trigonal and the second rhomboidal – but both, once placed on the respective tool, tackle the machining with the same 95° tool cutting edge angle and therefore with a 5° lead angle. From the point of view of versatility, so the number of possible operations, both tools would be similar. Therefore they would be able to carry out the exact same machining operations for us operators: turning of various types, shouldering, chamfers and radius.

Insert nomenclaturechart

The first letter of the code is perhaps the most important one, that is the one that every turner must surely know because it defines the shape of the insert. In this lesson we have seen them all, although as we have said, in reality the most common shapes are as follows:

Cable Cutters cuts 350 MCM Copper and 350 MCM Aluminum cableShears made of forged steel with black-oxide finish for long lifeShear-type hook jaws grab and hold cable while shear-cutting action makes clean cutsMade in USA with beveled tips for positive matingHinge bolt with pin-set nut for proper blade tensionNon-slip vinyl gripsDoes not cut steel or ACSR

Among the various shapes, we find exactly in the centre the C and W shapes. Both have an angle between the cutting edges of 80° and both, for one reason or another, are among the most popular.

ISOinsertchart

Reduced hand force for easier cuttingPatented two-step ratchet mechanism requires fewer strokes per cutCuts up to 336 MCM ACSR, 400 MCM Copper and 600 MCM AluminumQuick release lever opens blades easily in every cutting position, to allow removal of the cable before completion of cutHardened steel cutting blades for lasting strength and sharpnessLocking lever keeps handles closed for easy transport; fits in a tool box or bagSelectively-hardened blades and reduced hand force make it easier to cut ACSRCable Cutter Replacement Part List available for reference if needed

High-leverage pliers with rivet closer to the cutting edge for 36-percent greater cutting power than other plier designsDiagonal Cutters have short jaws and beveled cutting edges for close cutting of wireInduction-hardened cutting knives for long lifeHot-riveted joint ensures smooth action and no handle wobbleMade in USA with Custom, US-made tool steelState-of-the-art, dual-material Journeyman handles provide a better grip without sacrificing tool strength and durabilityHard, black material for toughness and durabilitySoft material on outer surface for comfort and a firm gripColor-coded handles allow quick identification of tool

Built to make clean cuts through even the thickest 1800 pair 24 AWG or 2700 pair 26 AWG lead or polyethylene-jacketed cable.Its maximum cutting capacity is 3-3/8 in. diameter

Lightweight, yet efficient shear-type cable cutterCuts lead or rubber-covered communications cableReplaceable hook-jaw blades grab and hold cable while shear-cutting action makes clean cutsExceptionally strong fiberglass handles with heavy vinyl grips for comfort and slip resistance and heavy-duty pins in head that serve as blade-stopsMade in USAJaws are forged tool steel with black-oxide finish for long lifeMake a clean, even cut for ease in fitting lugs and terminalsNot designed for cutting steel or ACSROverall Length: 37'' (940 mm) Weight: 8.55 lbs (3.9 kg) Communications Cable-Cutting Maximum Capacity: 900-pair soft copper and aluminum Soft Cable-Cutting Maximum Capacity: up to 2-1/4'' (57 mm) diameter

Rated for ACSR and up to 1000 AWG. The iTOOLco Ratchet Cutters feature an ergonomic telescoping handle to fit in tight locations. ACSR rated Telescoping handles for added leverage Cutting capacity of up to 1-3/4″ or 44mm Large, comfortable grip Includes handy carrying case Blades have a 6 year limited warranty

Because of its versatility and not only because of the number of operations it can perform but also because of the number of possible applications, from roughing to finishing, the C-type insert is undoubtedly the most widely sold and used insert in machine shops all over the world. It could be said that the C shape combined with its 95° lead angle has made the fortune not only of the insert manufacturers but also of us operators and workshop technicians, who have solved many problems with the use of this tool. In addition, the C shape placed on a different tool with a different lead angle would have a way of working with the so-called 100° recovery angle. In this way, the C-type insert would have 4 cutting edges instead of 2, making it one of the most affordable inserts.

Turning insertIdentification chart

The Jonard Tools RC-600 Ratcheting Cable Cutter is designed to cleanly cut copper (up to 600 MCM), aluminum (up to 750 MCM), and multi-conductor cable. This cable cutter features the following:Made of heat-treated carbon steel with induction-hardened cutting edges for maximum strength and durabilityUnique design allows you to hold and cut cables quickly and easilySpring-loaded mechanism on handles for automatic openingErgonomically designed handle with cushioned rubber grip for greater comfort and torqueThis cable cutter is not designed for use on ACSR or other steel cables

Lightweight, yet efficient shear-type cutting of 1-3/8-Inch diameter, 500 Cu, and 750 AlReplaceable hook-jaw blades grab and hold cable while shear-cutting action makes clean cutsExceptionally strong fiberglass handles with heavy vinyl grips for comfort and slip resistance and heavy-duty pins in head that serve as blade-stopsJaws are forged tool steel with black-oxide finish for long lifeMade in USABeveled tips ensure positive mating while the hinge on a rugged bolt with a pin-set nut maintains proper blade tensionMake a clean, even cut for ease in fitting lugs and terminalsNot designed for cutting steel or ACSRIncludes rubber sleeves

REL R-GS RATCHETING GUY STRAND CUTTER 7/16" Capacity, notched blades hold material, while ratchet produces easy, progressive cuts. Cuts: EHS guy strand Mild steel rods,Bolts and similar materialsClean, square cuts with minimal distortion. Mechanical advantage over manual cutters

First of all, let’s start by counting the number of cutting edges useful for our machining; the trigonal insert with its 6 cutting edges would be the master. The more cutting edges, the more pieces produced. Moreover, since the purchase cost of both inserts would be the same, the cost per cutting edge would be considerably in favour of the W-type insert; therefore, it will be cheaper per cutting edge. The W-type insert would definitely be the winner so far.

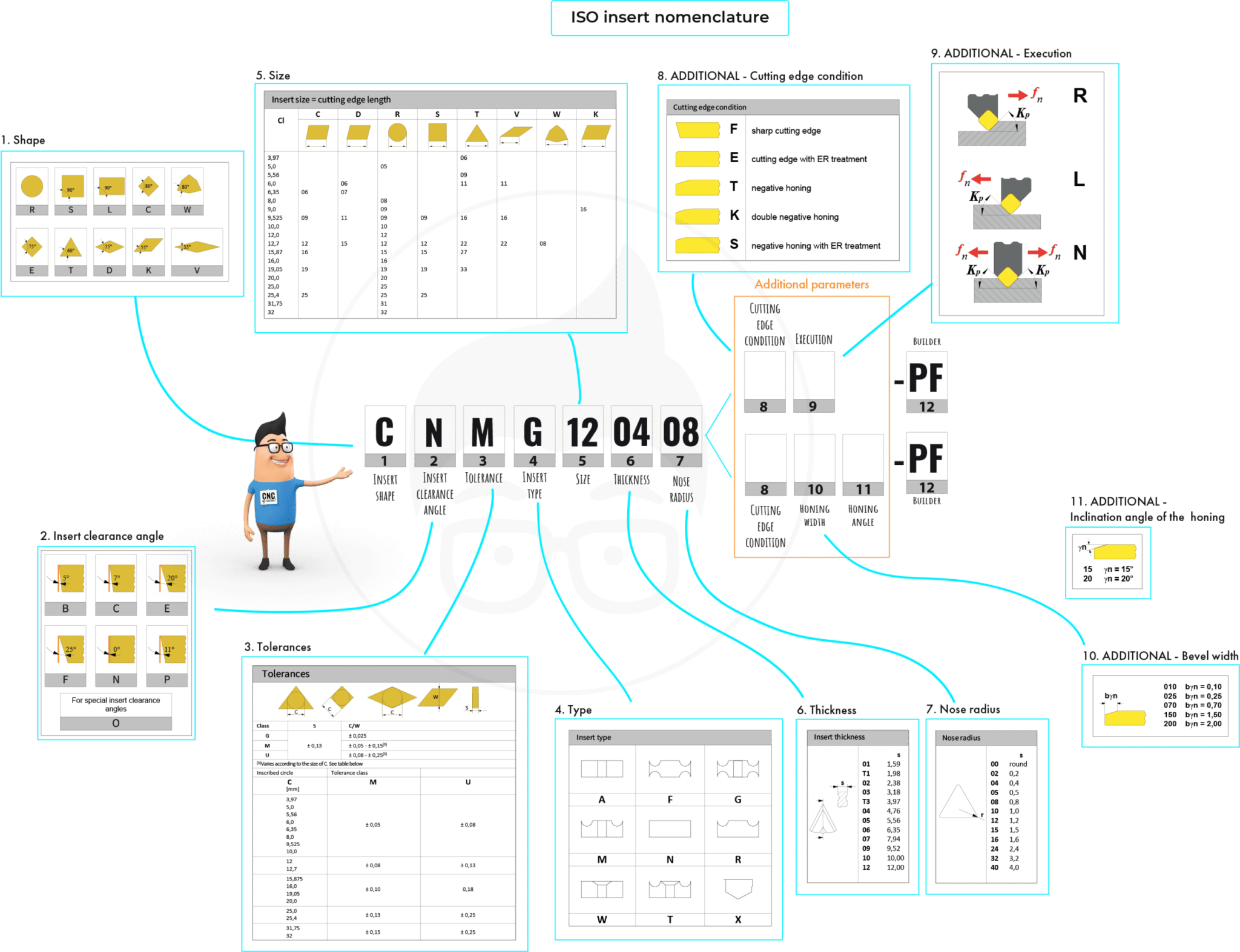

First of all, I would like to remind you that you can download the scheme of the ISO insert nomenclature. Keep it handy during today’s lesson and the next one, by clicking on the icon at the bottom right of the video. It will also come in handy on the machine.

ISOturning insert nomenclature

Carbideinsertidentification chart PDF

Hand Operated Ratchet Drive Cutter This light-weight, rugged ratchet drive cutter has been designed for cutting telecom cables especially where work space is tight. This ratcheting cutter features a thumb operated control which provides fast or slow opening of the cutter blades. Not for cutting steel, hard copper, or aluminum power cables.

As we said in the lesson, the choice of shape influences the strength of the insert and its versatility in making profiles.

Cable Cutters cut up to 1-Inch (2.5 cm) aluminum and copper coaxial cableShears feature precision, one-hand shearing action without compression or frayed endsForged body with heat-treated and precision-ground steel blades, withstands frequent cutting; Made in USAHot-riveted design requires no adjustment while maintaining a smooth, precise operationHandles are plastic-coated for maximum comfort and gripping powerWhen cutting drop wire with an inner steel conductor, we recommend diagonal-cutting pliers (Cat. No. D2000-28)HOW TO USE: Use a back-and-forth motion to score the cable until you reach the inner conductor. The inner conductor may then be cut by squeezing the handles firmly

Hand Operated Ratchet Drive Cutter This light-weight, rugged ratchet drive cutter has been designed for cutting telecom cables especially where work space is tight. This ratcheting cutter features a thumb operated control which provides fast or slow opening of the cutter blades. Not for cutting steel, hard copper, or aluminum power cables.

ANSIinsert nomenclature

Let’s take a closer look at some practical aspects of the C and W shape inserts. Let’s compare them on the assumption that they have the same nose radius, the same solid carbide grade and identical chipbreaker geometry.

Reduced hand force for easier cuttingPatented two-step ratchet mechanism requires fewer strokes per cutCuts up to 600 MCM Copper and 750 MCM AluminumQuick release lever opens blades easily in every cutting position, to allow removal of the cable before completion of cutHardened steel cutting blades for lasting strength and sharpnessLocking lever keeps handles closed for easy transport; fits in a tool box or bagFront-loading jaws for tight applicationsCable Cutter Replacement Part List available for reference if needed

It is probable that the W-type insert will fail when heavily loaded due to the micro-vibrations created by the precarious fixing. Consequently, it is no longer so certain that we can use all 3 of its cutting edges, contrary to what happens with the C-shaped insert where we can certainly use both cutting edges.

The C-type insert, on the other hand, has a much better positioning from this point of view, since two of its sides are all positioned in the insert slot. This aspect becomes important when we have to start using the inserts in roughing operations when depth of cut and feed rates are high. The fact of having better stability in the case of the C insert is a fundamental advantage for cutting edge life and machining success.

Cable Cutters with cable-gripping jaws quickly score jacket and insulation, and easily cut through copper inner conductorShear's blades cleanly cut aluminum and copper coaxial cable without compressoin and frayed endsForged body with heat-treated and precision-ground steel blades, withstands frequent cutting; Made in USAHot-riveted design requires no adjustment while maintaining a smooth, precise operationCompact, lightweight design fits perfectly in any professional's tool pouchHandles are plastic-coated for maximum comfort and gripping powerWhen cutting drop wire with an inner steel conductor, we recommend Cat. No. D2000-28 diagonal-cutting pliers

Designed especially for cutting communications cable up to 3-3/8 in. (85 mm) in diameter. Because of their small size, they are extremely popular for cutting cable in tight spots like manholes, ditches or riser closets.

This ingenious tool offers big cutter performance without long handles to tackle large cutting jobs in tight spaces such as manholes.

The special alloy and hardening process used in manufacturing GMP tabbing shears makes these the only ones to stand up to steel/aluminum shields. The lower snout is rounded and thinly contoured to fit smoothly between the cable shield and the core wrap without damaging conductors. A precision ground and sharpened cutter edge makes these the finest shears produced. For extra safety the formed handle grips keep your hand from sliding forward as cutting progresses and a latch keeps the handles closed for storage

In today’s lesson we looked at the first part of the ISO insert nomenclature for mechanically fixed inserts. To be precise we looked at the first 4 letters.

But does this way of thinking fit well with our chip volume and productivity? Is this really the most economical way? Of course, we would say yes if we stopped at this level. But we like to go into each topic in depth, so let’s think about it.

The Jonard Tools RC-600 Ratcheting Cable Cutter is designed to cleanly cut copper (up to 600 MCM), aluminum (up to 750 MCM), and multi-conductor cable. This cable cutter features the following:

Lightweight, yet efficient shear-type cable cutters cut 1000 MCM copper and 1200 MCM aluminum cableReplaceable hook-jaw blades grab and hold cable while shear-cutting action makes clean cutsExceptionally strong fiberglass handles with heavy vinyl grips for comfort and slip resistance and heavy-duty pins in head that serve as blade-stopsJaws are forged tool steel with black-oxide finish for long lifeMade in USAMake a clean, even cut for ease in fitting lugs and terminalsNot designed for cutting steel or ACSR

First of all, I would like to remind you that you can download the scheme of the ISO insert nomenclature. Keep it handy during today’s lesson and the next one, by clicking on the icon at the bottom right of the video. It will also come in handy on the machine. ISO insert nomenclature In today’s lesson we looked at the first part of the ISO insert nomenclature for mechanically fixed inserts. To be precise we looked at the first 4 letters. The first letter of the code is perhaps the most important one, that is the one that every turner must surely know because it defines the shape of the insert. In this lesson we have seen them all, although as we have said, in reality the most common shapes are as follows: As we said in the lesson, the choice of shape influences the strength of the insert and its versatility in making profiles. Among the various shapes, we find exactly in the centre the C and W shapes. Both have an angle between the cutting edges of 80° and both, for one reason or another, are among the most popular. C and W in comparison Let’s take a closer look at some practical aspects of the C and W shape inserts. Let’s compare them on the assumption that they have the same nose radius, the same solid carbide grade and identical chipbreaker geometry. C and W have different shapes – the first trigonal and the second rhomboidal – but both, once placed on the respective tool, tackle the machining with the same 95° tool cutting edge angle and therefore with a 5° lead angle. From the point of view of versatility, so the number of possible operations, both tools would be similar. Therefore they would be able to carry out the exact same machining operations for us operators: turning of various types, shouldering, chamfers and radius. So which one are we going to use? First of all, let’s start by counting the number of cutting edges useful for our machining; the trigonal insert with its 6 cutting edges would be the master. The more cutting edges, the more pieces produced. Moreover, since the purchase cost of both inserts would be the same, the cost per cutting edge would be considerably in favour of the W-type insert; therefore, it will be cheaper per cutting edge. The W-type insert would definitely be the winner so far. But does this way of thinking fit well with our chip volume and productivity? Is this really the most economical way? Of course, we would say yes if we stopped at this level. But we like to go into each topic in depth, so let’s think about it. Look at how the inserts are mounted on their respective tools; we should notice that the W-shaped insert would offer a slot with a more open contact angle due to its shape. The C-type insert, on the other hand, has a much better positioning from this point of view, since two of its sides are all positioned in the insert slot. This aspect becomes important when we have to start using the inserts in roughing operations when depth of cut and feed rates are high. The fact of having better stability in the case of the C insert is a fundamental advantage for cutting edge life and machining success. It is probable that the W-type insert will fail when heavily loaded due to the micro-vibrations created by the precarious fixing. Consequently, it is no longer so certain that we can use all 3 of its cutting edges, contrary to what happens with the C-shaped insert where we can certainly use both cutting edges. In our opinion, it should be used, for example, on machines where the working data are not so demanding. Its operations could be finishing and semi-finishing on materials that are not particularly difficult to machine. Because of its versatility and not only because of the number of operations it can perform but also because of the number of possible applications, from roughing to finishing, the C-type insert is undoubtedly the most widely sold and used insert in machine shops all over the world. It could be said that the C shape combined with its 95° lead angle has made the fortune not only of the insert manufacturers but also of us operators and workshop technicians, who have solved many problems with the use of this tool. In addition, the C shape placed on a different tool with a different lead angle would have a way of working with the so-called 100° recovery angle. In this way, the C-type insert would have 4 cutting edges instead of 2, making it one of the most affordable inserts. Used with recovery angles, it would certainly not be able to perform countless movements on the workpiece or remove large amounts of material. But within its field of application it would remain useful, also because the recovery angle assumes that the insert works at an angle between the cutting edges of 100°, so it is also very strong. This solution is successfully used in various sectors, for example when machining the surfaces of forged parts, roughing eccentric components where the interrupted cut affects the life of the insert. The first cut is often made in this way in order to improve and optimise production costs.

The Sheathing and Industrial Cutter, also known as a Lead Ringer, is perfect for soring the lead. It also enables the user to remove paper insulation up to desired point, neatly , quickly, safely and efficiently.Max Cable Capacity: 1-7/6" O.D.For added user comfort, the tools has heavy duty plastic-dipped handles.

0086-813-8127573

0086-813-8127573