Feed Rate and Cutting Speed in Machining - feed is measured in units of

With a wide range of machines to support, Machinists Inc. was unable to utilize them to their full capacity, necessitating the search for a CAM package that could keep up with their needs.

Copyright © 2024 chemicool.com Chemistry Dictionary | Birth of the Elements | Tools | Periodic Table | Citing Chemicool | About | Privacy | Contact

The names of both elements have their origins in the frustrations of miners caused by metal-arsenic ores: nickel arsenide and cobalt arsenide. Cobalt’s name is derived from the German ‘kobold’ meaning ‘goblin’ – a close relative of the creature from which nickel’s name was derived.

Machinists union

Isotopes: Nickel has 23 isotopes whose half-lives are known, with mass numbers 52 to 76. Naturally occurring nickel is a mixture of its five stable isotopes and they are found in the percentages shown: 58Ni (68.1%), 60Ni (26.2%), 61Ni (1.1%), 62Ni (3.6%) and 64Ni (0.9%). The most abundant isotope is 58Ni at 68.1%

Seattle machine shop

In the early twentieth century, Ludwig Mond patented a process using nickel carbonyl to purify nickel. This process is still used today.

“NX is the software that seemed like it supported everything from top to bottom. We could get mill-turn support, support on our 5-axis and very complex, very intricate code. We could also get fairly rudimentary code that worked on older 3-axis boring mills. At the end of the day, that’s kind of what drove our decision towards NX.”

Harbor Island Machine Works

After an extensive search for a better tool to program their machines to the best of industry, Machinists Inc. found it with Siemens NX. Relying on Applied CAx for on-site training and mentorship, Machinists Inc. successfully transitioned to NX.

After an exhaustive search that included trial runs with several different software packages to perform testing, MI looked at Siemens NX. This, in turn, introduced Machinists Inc. to Applied CAx, a Siemens partner that are not only experts with the software but offers a high level of technical support thanks to operations that include a working machine shop where the tools are not only utilized but pushed to their capacity.

Workers who have breathed very large amounts of nickel compounds have developed chronic bronchitis and lung and nasal cancers.

There is a satisfying symmetry in this discovery. Cronstedt was a pupil of George Brandt, who had discovered cobalt, which sits immediately to the left of nickel in the periodic table.

Artifacts made from metallic meteorites have been found dating from as early as 5000 BC – for example beads in graves in Egypt.(1)

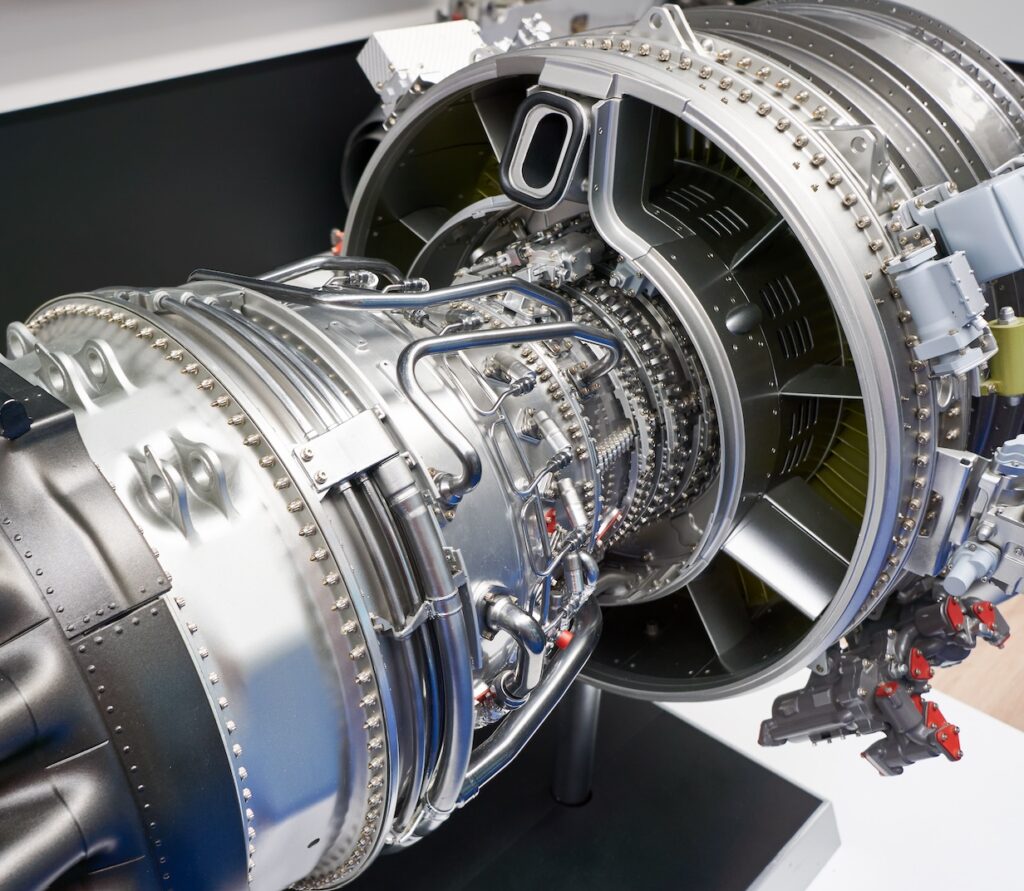

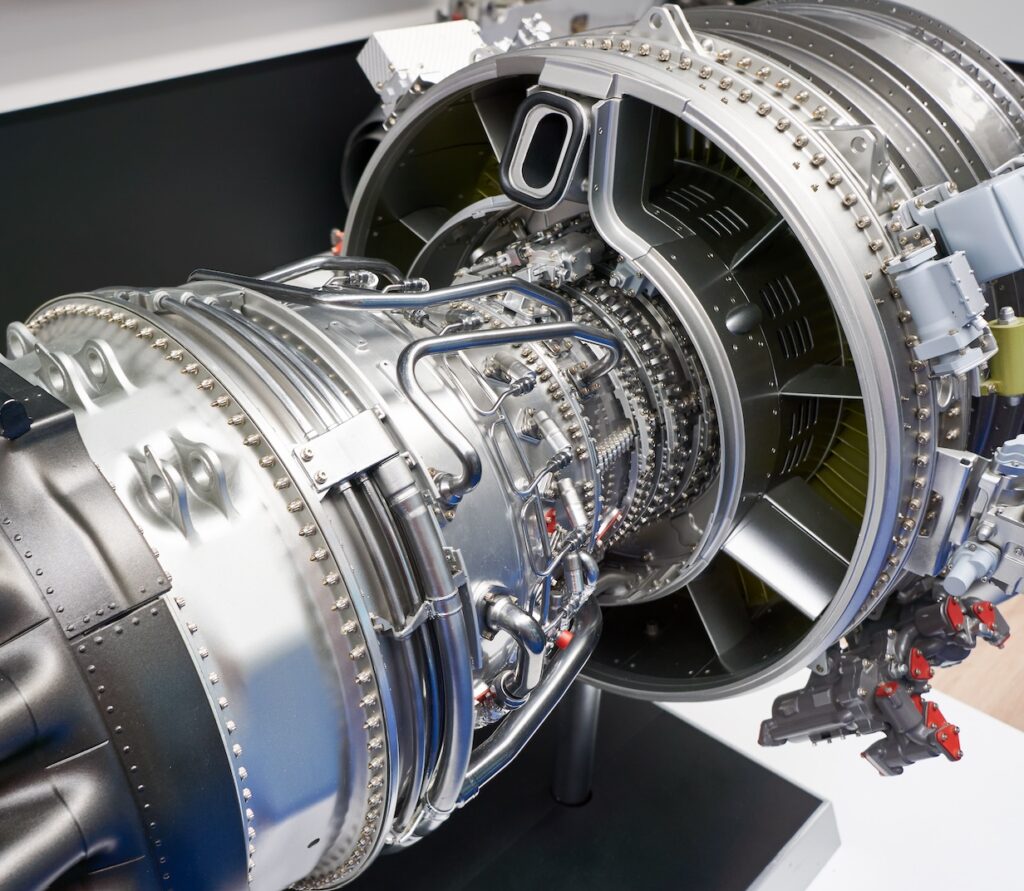

Located in South Seattle, Machinists Inc. has been operating since 1941, serving the maritime, aerospace, research, and transportation industry. Maintaining 7 plants with over 250,000 sq. ft, they’re the largest precision machining shop in the Northwest. With a diverse range of machines to support, some of which feature very large working envelopes, MI maintains up to date, specialized equipment operated by an experienced team of multi-discipline engineers and machinists. Operating advanced CNC milling machines requires specialized tools. After adding an FPT Verus 250 high-performance 5-axis machine to the shop, they spent two years struggling to write post processors for it. As their existing software couldn’t support the kinematics, it necessitated a search for a CAM package that could better support their needs.

After finding that its chemical reactions were not what he would have expected from a copper compound, he heated kupfernickel with charcoal to yield a hard, white metal, whose color alone showed it could not be copper. Its properties, including its magnetism, led him to conclude that he had isolated a new metallic element.

With a working knowledge of the progressive software platform NX provides, Machinists Inc. has achieved dramatic reductions in their programming times. Utilizing NX automation tools has opened up new options in their workflow. Being able to run simulations within CAM has eliminated the need for additional software such as Vericut. Theyʼre also achieving high reuse from their developed templates and posts.

Hi Nataiya, Nickel with 31 neutrons is radioactive, and there isn’t much of it anywhere! Nickel’s atoms can have as few as 24 neutrons to as many as 48 neutrons. 68.1% of nickel atoms have 30 neutrons. ?

thank you this helped me so much im doing a poster in school about nickel and i got my poster all done with this website

The chemical element nickel is classed as a transition metal. In the 1750s nickel was discovered to be an element by Axel Cronstedt.

Tubing made from a copper-nickel alloy is used in desalination plants. This alloy is naturally resistant to corrosion by seawater and to biofouling.

The first meteorite ever photographed on another planet. In 2005 NASA’s Mars rover Opportunity used spectrometers to discover that this basketball-size meteorite was mainly iron and nickel. Image by NASA/JPL/Cornell.

Machinistsinclinkedin

In cobalt’s case, miners mistakenly thought the ore contained silver, and called the ore kobold in frustration at the wicked goblins who they believed were preventing them getting silver from the ore.

In the 1600s, a dark red ore, often with a green coating, had been a source of irritation for copper miners in Saxony, Germany. They believed the dark red substance was an ore of copper, but they had been unable to extract any copper from it.

Machinistsalary

Nickel is taken from its ores by roasting and reduction processes which produce a metal of over 75% purity. The Mond process is then used to purify the nickel further.

Source: Nickel occurs occasionally free in nature but is mainly found in ores. Its chief ores are pentlandite and pyrrhotite (nickel-iron sulfides), garnierite (nickel-magnesium silicate), millerite (nickel sulfide) and niccolite (nickel arsenic).

Between 1751 and 1754, the Swedish chemist Axel Cronstedt carried out a number of experiments to determine the true nature of kupfernickel. (We now know that kupfernickel is nickel arsenide, NiAs.)

Machinist incjobs

“Weʼre looking forward to continuing with Applied CAx as weʼre on maintenance and needing support – we will always need support, it can be a daunting programming system, but thereʼs a lot of capability there and we definitely see it as the path forward in the future”

Washington Machine Works

In frustration, they had named it ‘kupfernickel’ which could be translated as ‘goblin’s copper’ because clearly, from the miners’ point of view at any rate, there were goblins or little imps at work, preventing them extracting the copper.

Miners in Germany believed little fellows like this one had stopped them extracting copper and silver from nickel and cobalt arsenides. Fortunately George Brandt and Axel Cronstedt took a more scientific approach to the problem and discovered two new elements. Image by JNL.

Starting with an online demonstration, Applied then came onsite to perform a number of demonstrations around the five-axis abilities and capabilities of NX cam. For MI, the most important thing was directly seeing how NX would process their parts and fit not just with the resources on hand, but tools and resources Machinists Inc. might acquire in the future.

Nickel is also used in batteries – for example NiCd (nickel-cadmium) and Ni-MH (nickel-metal hydride) rechargeable batteries – and in magnets.

Nickel and its compounds are considered to be carcinogenic. Approximately 10 to 20 percent of people are sensitive to nickel. Repeated contact with it leads to skin complaints (dermatitis). Such people should avoid contact with nickel, which can be found in jewelry.

Increased productivity with less troubleshooting thanks to significantly reduced programming times, utilizing NX automation and simulation tools to meet and exceed their goals. Thanks to more accurate code, MI is now able to utilize their machines to the best of ability and achieve more sophisticated product requirements.

After Machinists Inc. was sold on NX and its capabilities, the challenge of training staff and transitioning to the software began. Starting with several sessions of onsite training, Applied engineers followed up with mentorship that stepped in weekly to help answer questions and troubleshoot challenges that came up.

0086-813-8127573

0086-813-8127573